Williams Applies 3D Printing to Optimize the Electric Rallycross FC1-X

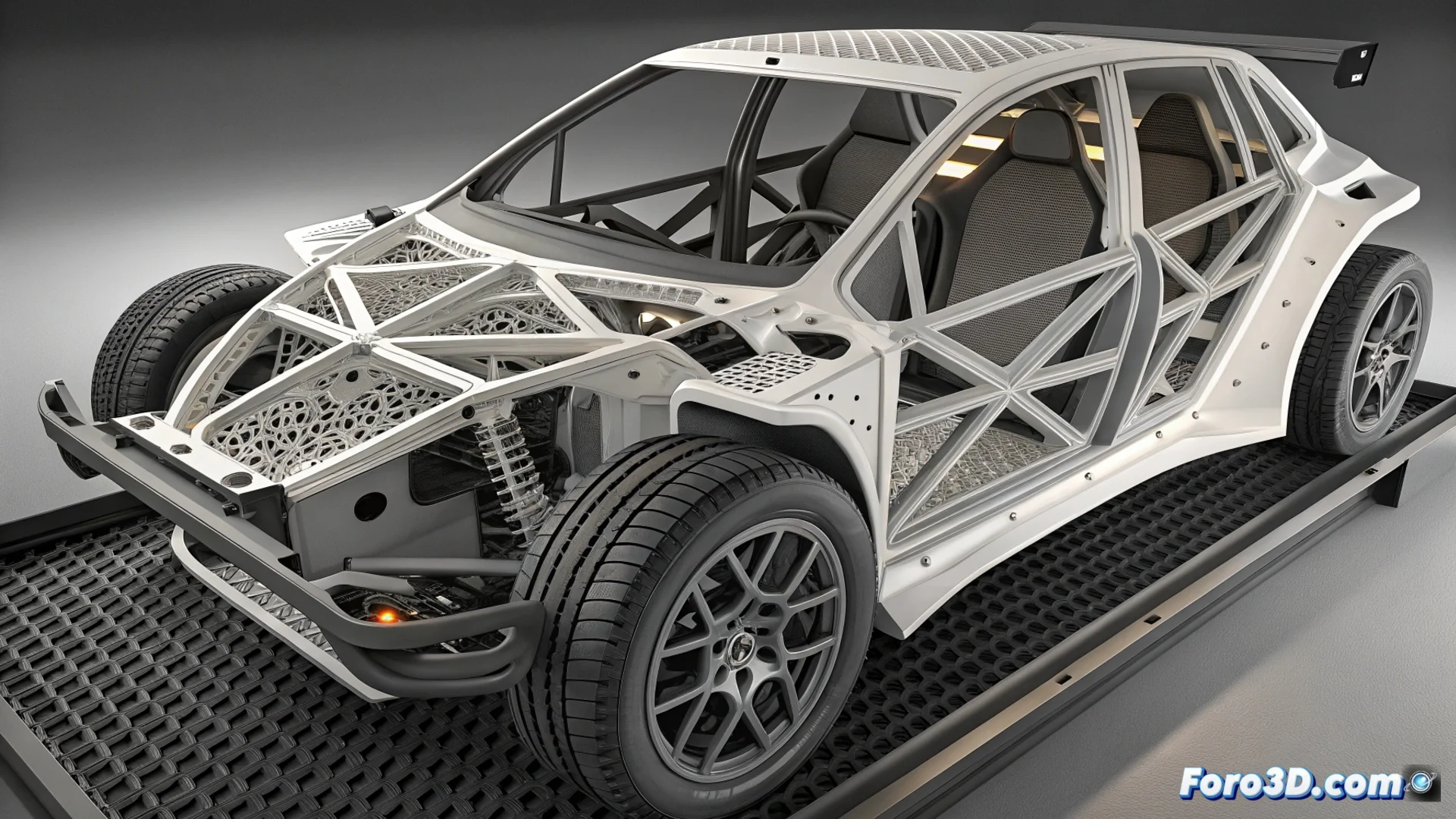

The Williams Advanced Engineering team is transforming how competition vehicles are built. Their current focus is the electric rallycross car FC1-X, where additive manufacturing is key to producing essential components. This technology enables the creation of parts with intricate shapes that conventional methods cannot achieve, concentrating on two vital areas: battery system protection and elements that define airflow. 🏎️⚡

Integrating Complex Functions into a Single Structure

By 3D printing these parts, engineers can incorporate specific features directly into the component's geometry. This not only simplifies assembly but also optimizes performance from its core. The process fuses design and functionality in a way that was previously unfeasible.

Key advantages of this approach:- Create complex internal geometries to manage impacts and dissipate heat simultaneously.

- Reduce the vehicle's total weight by using fewer parts and more efficient materials.

- Consolidate multiple functions, such as structural protection and cooling ducts, into a single manufactured element.

3D printing allows us to iterate designs at a speed that redefines our development cycle for extreme competition.

Composite Materials for Extreme Challenges

The parts are produced with advanced composite materials, which blend polymers with fiber reinforcements. This combination provides great mechanical strength while maintaining minimal weight. The internal geometry is designed with a dual purpose: absorb the energy from an impact to safeguard the high-voltage battery and, at the same time, direct airflow through integrated channels to cool the electrical systems during the race.

Functions of the internal design:- Structures that manage and distribute the force of an impact.

- Air channels that dissipate heat from power electronics components.

- Optimize the balance between robustness, lightness, and thermal efficiency.

Accelerate Development and Customize Performance

This method greatly accelerates the vehicle development process. Teams can test and modify new component designs much faster than with traditional molding or machining techniques. Additionally, additive manufacturing facilitates adapting parts for specific circuits or adjusting the car's behavior according to track conditions. This optimizes aerodynamics, protection, and thermal management in a single workflow. Although its appearance may resemble a video game, these printed components are made to withstand the most real and demanding conditions of rallycross. 🚥