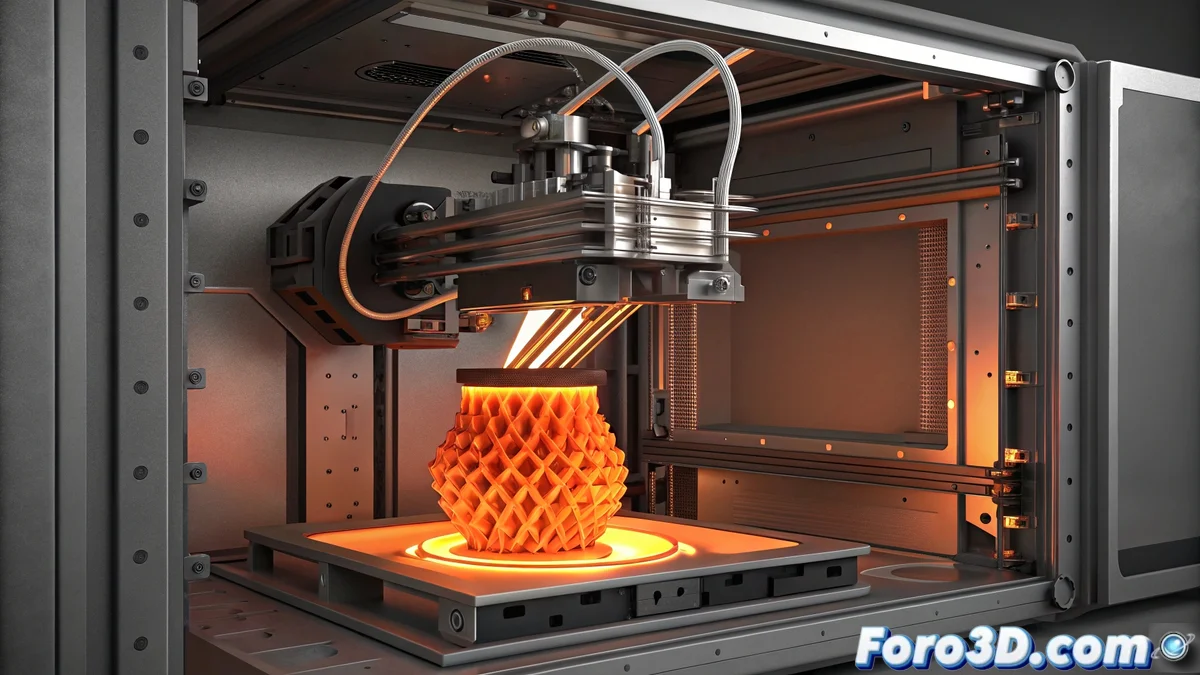

Vision Miner presents the 22 IDEX v4 industrial 3D printer for high-performance materials

The specialized company Vision Miner has just introduced to the market the 22 IDEX v4, an industrial additive manufacturing equipment specifically designed to process advanced technical materials that require extreme thermal conditions during printing. This solution incorporates an innovative fully independent dual extrusion system that facilitates working with high-performance filaments such as PEEK, PEKK, or ULTEM, while maintaining a hermetically sealed thermal chamber capable of reaching temperatures up to 200°C. 🏭

State-of-the-art technical specifications

The manufacturing platform features a build volume of 500x500x600 mm and implements a high-precision toothed belt movement mechanism that significantly reduces vibrations during the process. The IDEX system (Independent Dual Extruder) allows the use of two different materials simultaneously or the combination of main filament with soluble support material, completely eliminating the risks of cross-contamination. The heated chamber provides uniform thermal distribution, while the print bed with garolite surface ensures exceptional adhesion even with the most complex compounds.

Key features:- Toothed belt movement system that minimizes vibrations and ensures micrometric precision

- Control via intuitive touch interface that simplifies operation and job programming

- Robust structure with industrial components that ensure repeatability in production environments

The 22 IDEX v4 represents a qualitative leap in industrial 3D printing, combining extreme thermal capacity with manufacturing precision for demanding technical applications.

Implementation in specialized industrial sectors

This equipment finds its greatest utility in regulated and high-demand industries such as aerospace, automotive, and medical, where components capable of withstanding extreme temperature, chemical pressure, and mechanical stress conditions are needed. It enables the manufacture of production tools, functional prototypes, and end-use parts that were traditionally produced by CNC machining or injection molding, drastically reducing development times and associated costs.

Main applications:- Manufacturing of lightweight and ultra-resistant components for aeronautics and competition automotive

- Production of customized medical devices and sterilizable surgical tools

- Development of functional prototypes and short runs for validation in extreme environments

Practical implementation considerations

Users should consider that this high-performance technology entails significant energy requirements, as maintaining the chamber at extreme temperatures consumes considerable electrical power. However, this investment is fully justified by the unique capabilities it offers for processing advanced engineering materials, meeting the most stringent standards of highly regulated industries. The machine positions itself as a comprehensive solution for producing technical components with superior mechanical properties. 💡