The Rosalind Franklin Rover's Drill Bit is Manufactured Using Metal 3D Printing

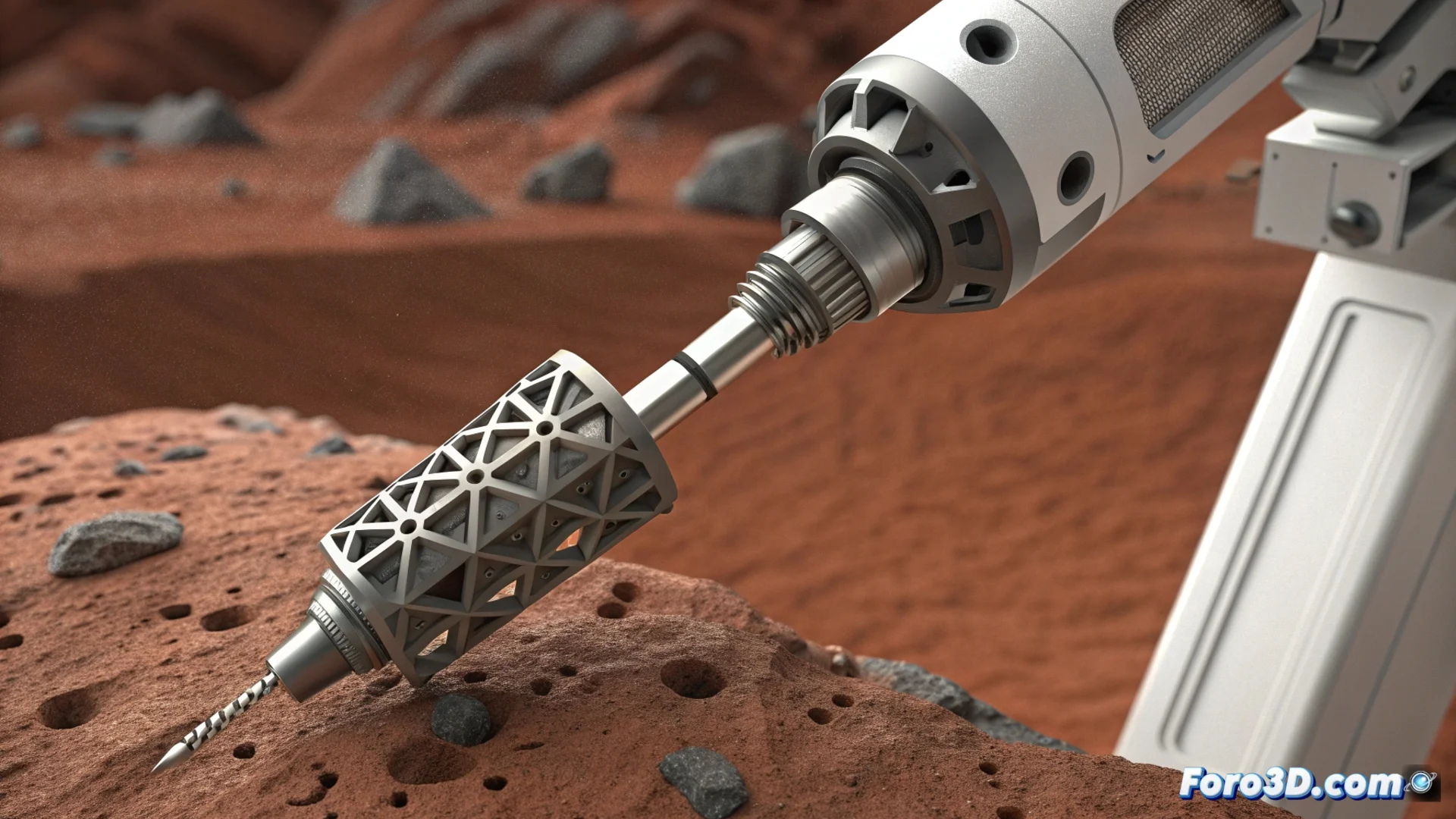

The European Space Agency (ESA) has produced an essential component for its next Mars rover using metal additive manufacturing. This is the main drill bit of the drill that will equip the Rosalind Franklin rover, a key piece for the ExoMars mission developed by the ESA and Roscosmos. Its objective is to drill into the Martian subsurface and extract samples where traces of ancient life might be preserved. 🔩

A Mission to Search for Life Beneath the Martian Surface

The rover is designed to drill and collect samples from up to two meters deep. At that distance from the surface, the material is protected from cosmic radiation and oxidants that degrade organic compounds. This significantly increases the chances of detecting biosignatures, if they ever existed. The drill bit manufactured using 3D printing is the element that makes this sampling possible in an extreme environment.

Key Advantages of Manufacturing the Drill Bit Using 3D Printing:- Allows the creation of complex internal geometries that are impossible to machine with traditional techniques.

- Integrates multiple functions into a single piece, reducing the number of joints and potential failure points.

- Generates very little waste material and requires fewer steps to produce a ready-to-use part.

In space exploration, every gram counts and reliability is critical. Metal 3D printing offers solutions to these engineering challenges.

Optimized Internal Geometry for a Unique Purpose

Additive manufacturing technology has enabled the design of internal channels and a cavity with a specific shape inside the drill bit. This special geometry not only makes the part more robust to withstand drilling in Martian soil but is also optimized to retain and protect the collected regolith. The process builds the part layer by layer, melting steel powder with an energy source, resulting in a solid and reliable structure.

Process and Testing Features:- Steel powder is used, selectively melted with a laser or electron beam energy source.

- The ESA and its industrial partners subject the parts to exhaustive testing that simulates the harsh Martian conditions.

- Validating each component is essential to ensure its operation during the mission, as it cannot be repaired on Mars.

Less is More: The Philosophy of Modern Space Exploration

This project exemplifies how metal 3D printing solves space engineering problems. Replacing a complex assembly with a single printed piece increases reliability, reduces weight, and simplifies logistics. For the ExoMars mission, this means the Rosalind Franklin rover will have a more efficient and resilient tool to achieve its ambitious scientific goal: seeking answers about life on the red planet. 🚀