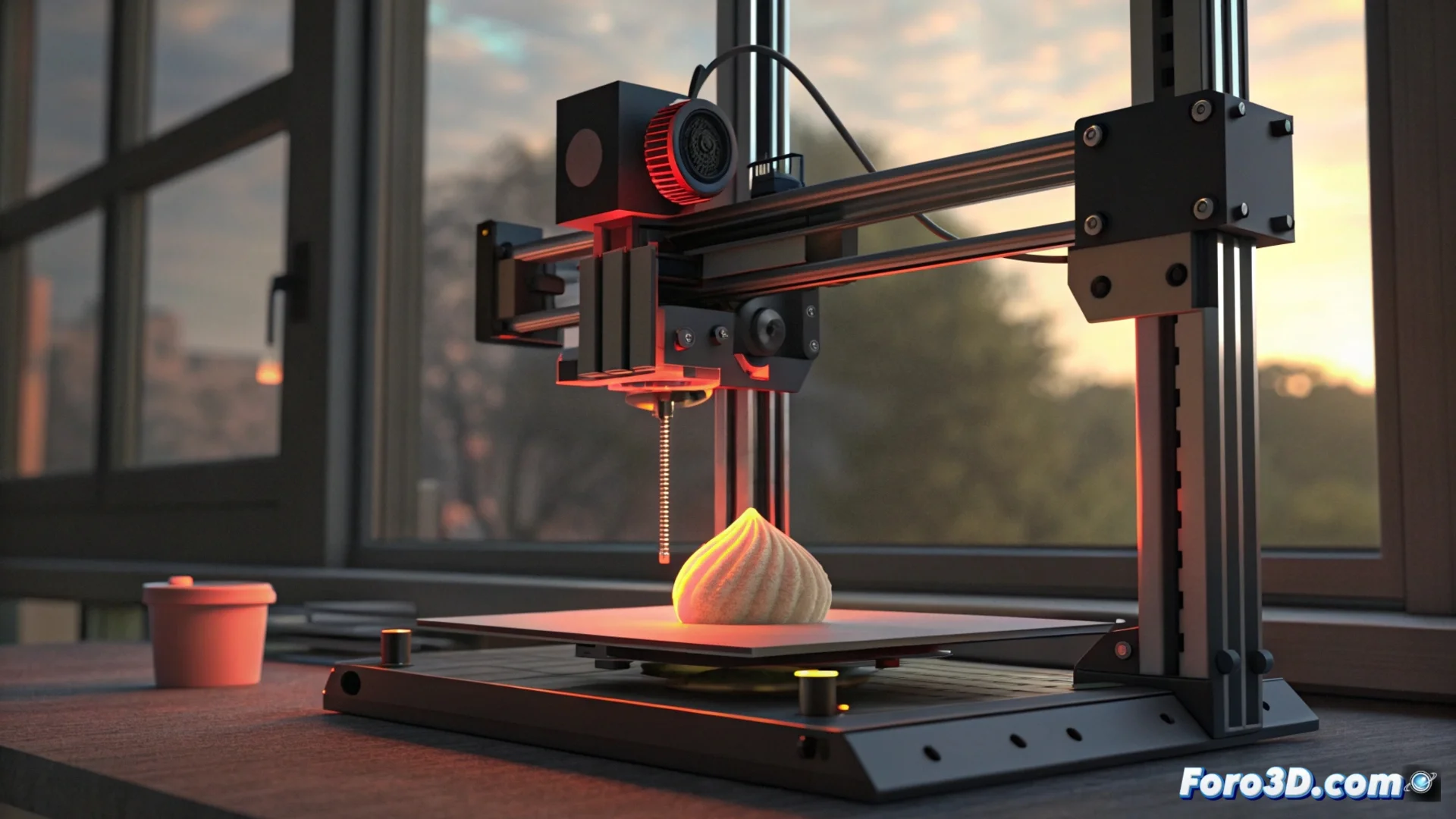

The power outage recovery function in FDM printers is not reliable

Many 3D printers using Marlin firmware include an option to resume a print after the power goes out. However, this tool is far from perfect and often creates more problems than it solves. Its operation depends on several factors that often escape the user's control. ⚡

The recovery mechanism and its weak points

For the system to work, the machine must save the print state to a non-volatile memory. This process is critical, and if power is interrupted right while writing, the data can be corrupted and become useless. Even when the information is saved correctly, the physical challenge of repositioning the head with millimeter precision is enormous. A minimal misalignment, especially on the vertical axis, can completely ruin the work.

Reasons why recovery fails:- Saving progress to memory can corrupt if the outage is abrupt.

- Recovering the horizontal position (X and Y) is easier, but the real problem is repositioning the Z axis precisely.

- Small mechanical slips, an imperfectly leveled bed, or the part having moved invalidate the saved height reference.

The function promises to save a twenty-hour print, but sometimes the remedy is worse than the disease, leaving a mark on the part.

The big challenge: the Z coordinate

While for the X and Y axes the head can lightly touch the part to find its place, the Z height is a dangerous unknown. If the nozzle is positioned just a fraction of a millimeter lower than it should be, it will drag and deform the already deposited plastic. If, on the other hand, it is higher, a visible gap between layers will be created, generating a fragile point in the part's structure. This lack of reliability is the Achilles' heel of the function.

Consequences of an error in repositioning the Z axis:- Nozzle lower: Collision with the part, dragging of material, and surface damage.

- Nozzle higher: Separation between layers, gap