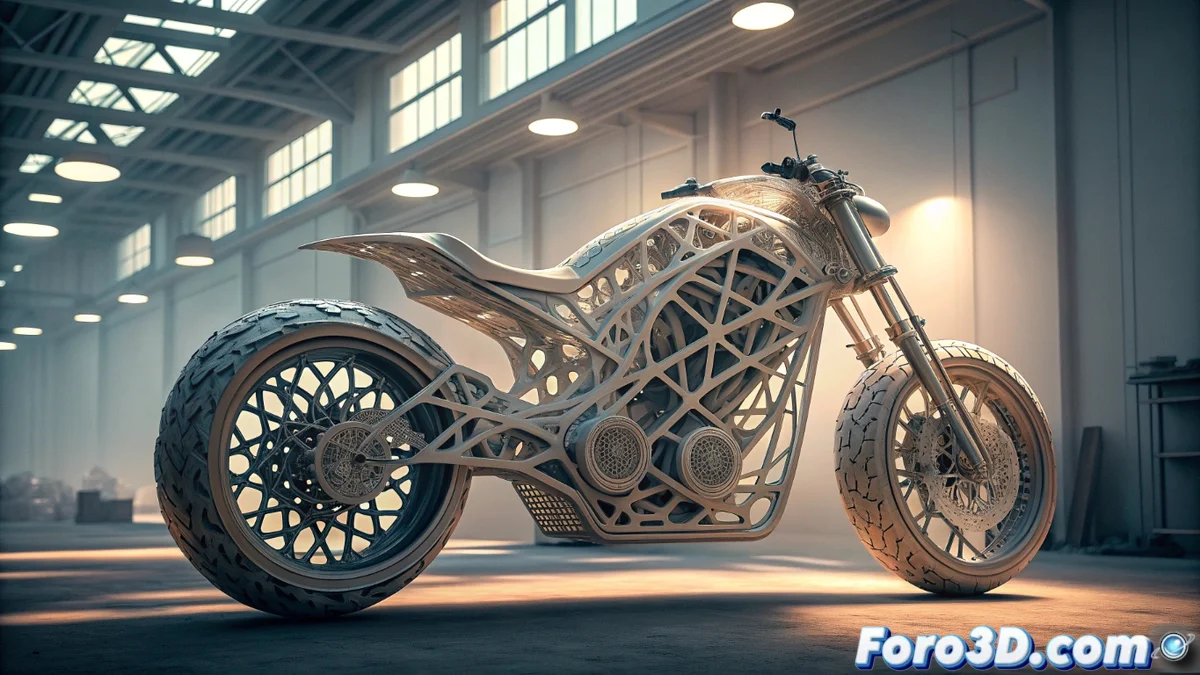

The Light Rider Electric Motorcycle and Its 3D-Printed Chassis by APWorks

Light mobility takes a technological leap with a Airbus project. Its subsidiary, APWorks, has brought the Light Rider to life, an electric motorcycle that goes beyond the prototype concept to become a practical demonstration. Its most revolutionary element is a chassis or monocoque entirely manufactured with metal 3D printing, marking a milestone by using this technology as the main structure of a real vehicle. This approach enables a radical design and superior performance compared to traditional methods. 🏍️⚡

The Winning Combination: Aerospace Alloy and Nature-Inspired Design

The key to low weight and high strength lies in the material and its application. The chassis is printed with Scalmalloy, a patented aluminum, magnesium, and scandium alloy, renowned in the aerospace sector for its exceptional strength-to-weight ratio. APWorks applied a bionic design, mimicking the efficiency of bone structures, to deposit material only where strictly necessary. The result is not a solid piece, but an intricate network of tubes and organic shapes.

Key Chassis Features:- Ultralight Weight: Just 6 kg, comparable to a full school backpack.

- Hollow Structure: Complex network that maximizes rigidity and minimizes mass.

- Single-Piece Manufacturing: Consolidates multiple components into one printed element, eliminating weak joints.

The Light Rider is tangible proof that additive manufacturing is ready to build safe, lightweight, and complex primary structures.

A Legacy That Redefines Vehicle Manufacturing

Beyond being a record, this project symbolizes a paradigm shift. Additive manufacturing enables unprecedented integration, reducing the number of parts, material waste, and simplifying assembly. This methodology opens the door to mass customization without the costly molds or tooling of series production.

Advantages of the Additive Manufacturing Paradigm:- Waste Reduction: Material is deposited only where needed, unlike subtractive machining.

- Impossible Geometries: Allows creation of the organic and optimized shapes of bionic design.

- Simplified Assembly Line: Fewer parts mean faster assembly with fewer errors.

The Future, Built Layer by Layer

Although its production was limited, the Light Rider's legacy is profound. It demonstrates conclusively that metal 3D printing has matured enough to take on critical structural roles. This advance paves the way not only for motorcycles, but for the next generation of cars, drones, and aerial vehicles, where lightness, geometric complexity, and efficiency will be fundamental requirements. The future of mobility could literally be printed. 🚀