When 3D Printing Reaches Literal New Heights

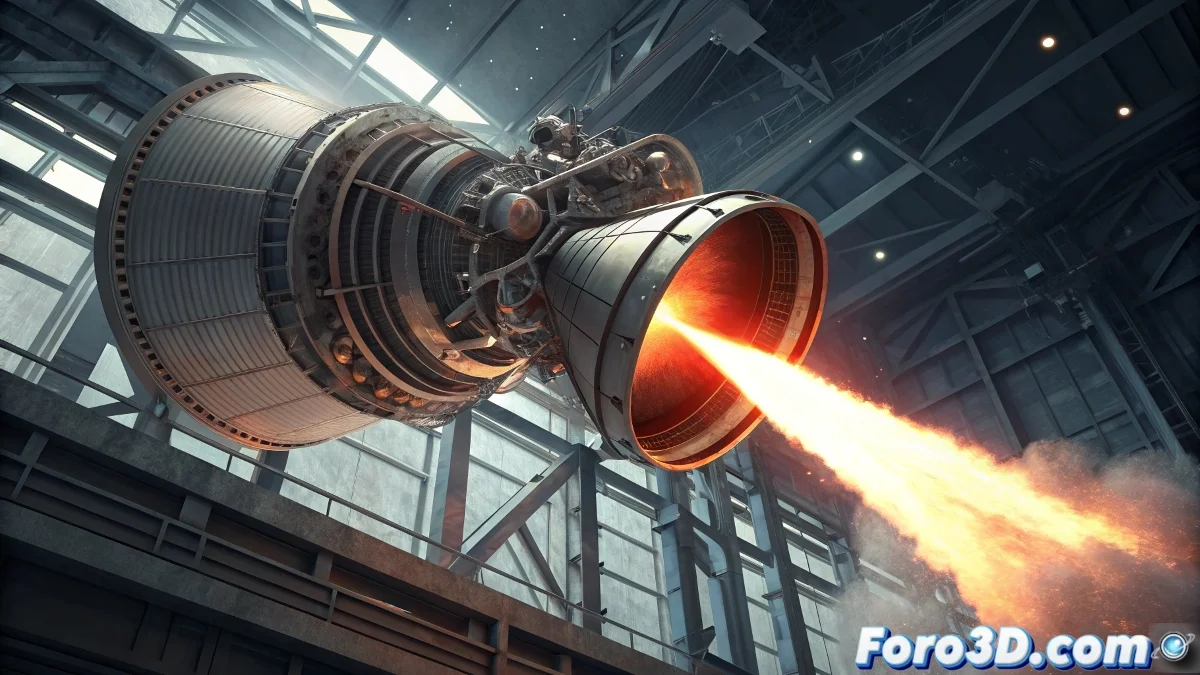

The aerospace industry has just witnessed a historic milestone with the creation of the first three-dimensionally printed rocket engine in a single piece using Inconel, a superalloy capable of withstanding extreme temperatures. This achievement represents not only an impressive technical advance, but a complete redefinition of how space thrusters are manufactured. Where previously hundreds of individual components and thousands of hours of assembly were required, now a continuous print suffices to produce a fully functional engine.

Inconel, known for its exceptional resistance to oxidation and creep, has been the preferred material for decades for jet and rocket engine components. However, its difficulty to machine using traditional methods has always represented a significant challenge. 3D printing solves this problem by allowing the creation of complex internal geometries that would be impossible to mill or cast, optimizing fuel flow and the engine's overall performance.

Revolutionary Advantages of This Approach

- 80% reduction in total manufacturing time compared to traditional methods

- Complete elimination of welded joints that represented structural weak points

- Internal optimization of ducts and chambers for maximum performance

- Significant reduction in weight without compromising structural integrity

The Printing Process That Made It Possible

The manufacturing of this engine required the development of specialized metal 3D printing techniques, particularly powder bed fusion with high-power laser. The process involved depositing ultrafine layers of Inconel powder that were selectively fused by a laser, gradually building the engine's complex geometry from the base to the nozzle. Each layer was monitored with artificial vision systems to detect possible defects in real time.

The simplicity of a single piece hides the complexity of its creation

Most notably, the print included not only the external structure, but all internal ducts, cooling channels, and the combustion chamber in a monolithic construction. This structural integrity significantly improves the engine's reliability, eliminating failure points associated with joints between components. The result is a thruster that can better withstand extreme vibrations and thermal loads during launch.

Implications for the Space Future

- Faster production of engines for urgent space missions

- Possibility of on-site manufacturing using local materials on other planets

- Easy customization of engines for specific missions without additional cost

- Dramatic reduction in costs for developing new propulsion designs

This advance brings closer the possibility of manufacturing critical rocket components on demand, reducing the need to maintain large spare parts inventories. For private space companies and government agencies, it represents an opportunity to accelerate development and testing cycles for new propulsion designs. The ability to iterate quickly on engine designs could significantly accelerate space exploration in the next decade.

Those who thought that 3D printing with metals was still experimental technology probably didn't expect it to already be producing engines capable of reaching space 🚀