Eindhoven University of Technology and Motion Imager Research Volumetric 3D Printing

A strategic alliance between the Eindhoven University of Technology (TU/e) and the company Motion Imager marks a step forward in additive manufacturing. Together, they will explore the frontiers of volumetric 3D printing, a paradigm that promises to transform how we conceive of producing objects. 🚀

A Leap Beyond Layers

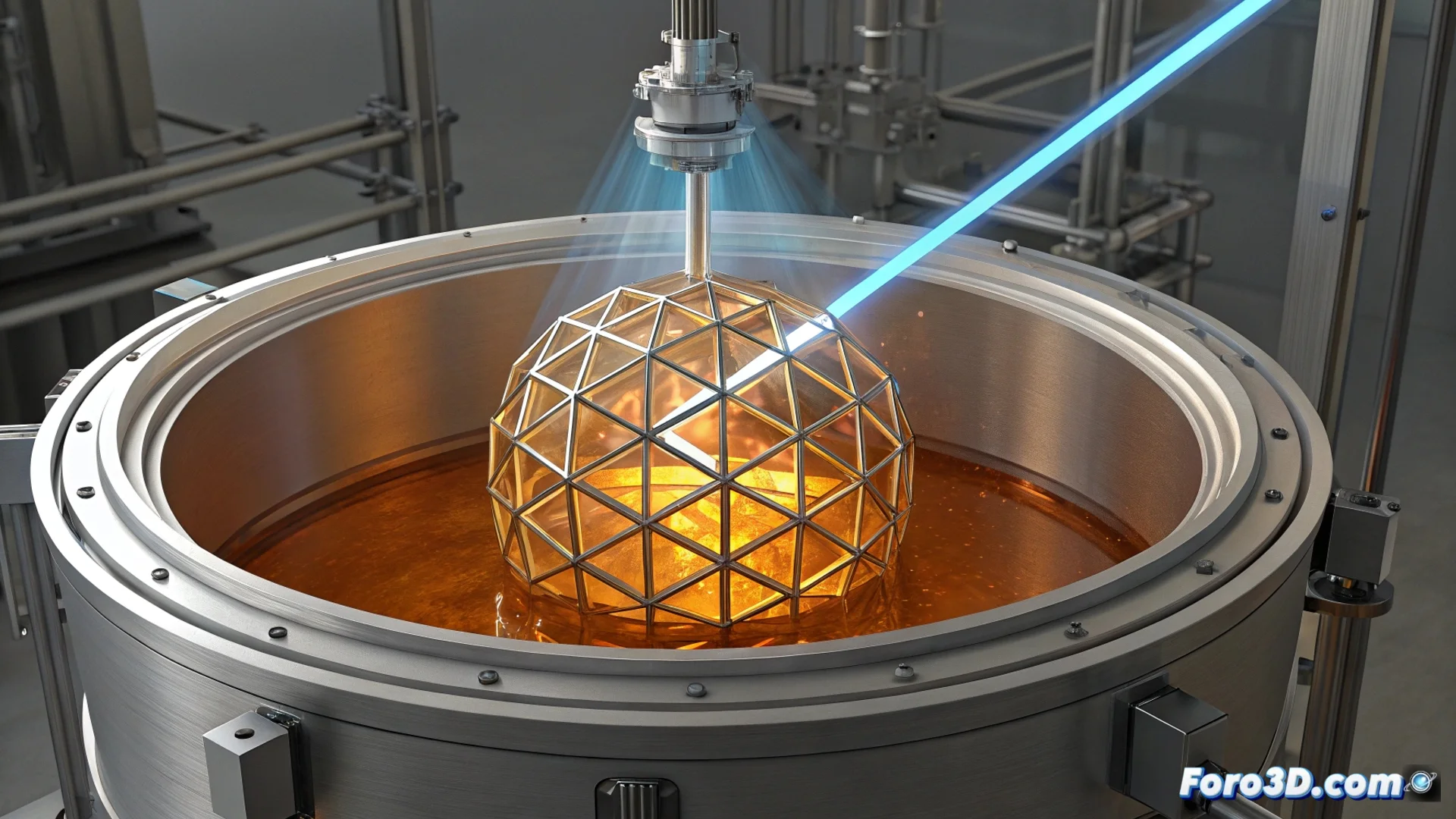

This technique abandons the traditional method of depositing material layer by layer. Instead, it projects light patterns into a volume of photosensitive resin, solidifying the complete geometry simultaneously. This approach eliminates layer marks, generates smoother surfaces, and reduces manufacturing times to seconds for intricate parts.

Key advantages of the volumetric process:- Manufacture complex objects in a single operation, without the need for support structures.

- Achieve superior surface quality by avoiding lines between layers.

- Drastically accelerate the production cycle compared to conventional additive methods.

The collaboration combines TU/e's academic expertise in photonics and materials science with Motion Imager's cutting-edge projection technology.

Focusing on Industrial Applications

The project is not limited to a laboratory demonstrator. Its main goal is to solve complex manufacturing challenges in high-value sectors. The research aims to enable this technology to handle polymers with specific mechanical properties and achieve scaling of the size of producible parts.

Target application sectors:- Medical devices: For manufacturing implants or tools with customized internal geometries.

- Aerospace components: Where lightweight parts with optimized designs are needed.

- End-use component manufacturing: The ultimate goal is to create a robust system for producing ready-to-use parts, not just prototypes.

The Road Ahead

Although the promise is great, the consortium must overcome current technical limitations. Scaling the process and expanding the library of usable materials are the main focuses. If successful, we could approach a reality where manufacturing a customized and complex part is no longer a bottleneck. For now, the method remains in the development phase, but its potential to redefine additive manufacturing is undeniable. 🔬