The Bambu Lab Printer Detects Low Flow in the Liquid Cooling

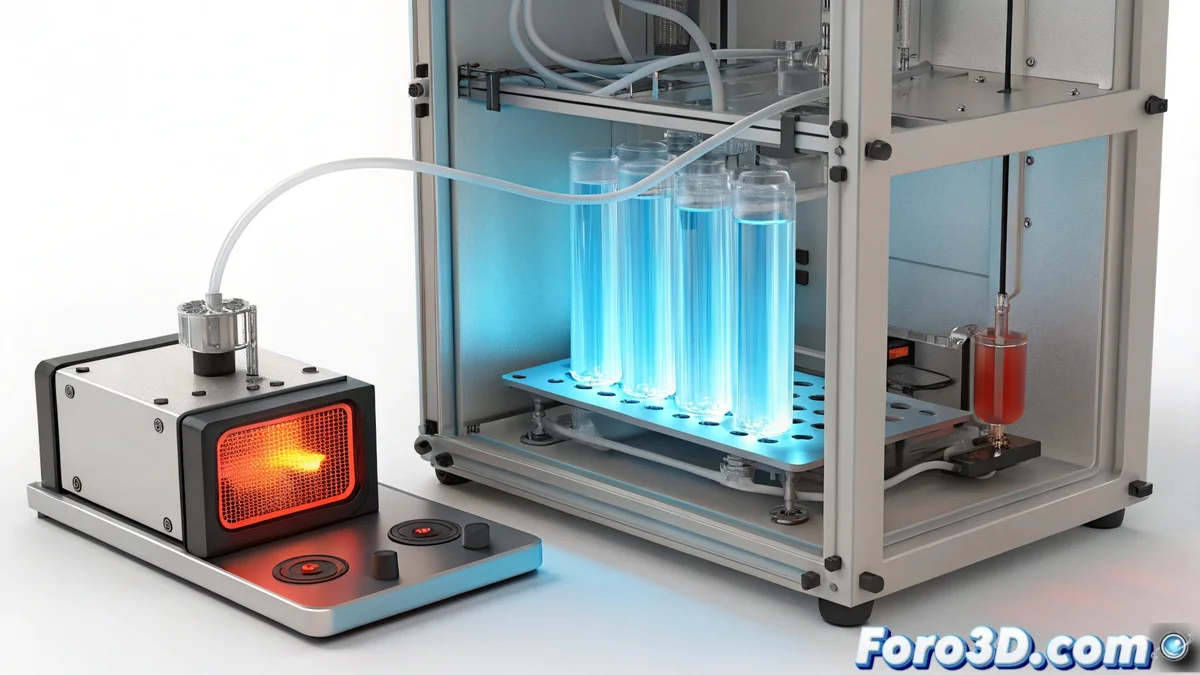

When a Bambu Lab printer displays the code HMS_0D00-0100-0001-0012, it is communicating a critical problem: the liquid cooling system is not moving enough fluid. An internal sensor detects that the flow is lower than necessary, which can overheat the hotend or the stepper motors, causing print failures or an emergency stop. 🚨

Diagnose the Origin of Insufficient Flow

This error acts as an early warning. Ignoring it can damage sensitive components due to excessive temperature. The core of the problem is always a restricted or interrupted coolant flow, and to solve it, a methodical process must be followed.

Initial Steps for Inspection:- Check the Main Reservoir: Confirm there is enough coolant liquid. A low level is the simplest and most common cause.

- Examine Hoses and Couplings: Physically look for kinks, twists, crushes, or disconnections that obstruct the liquid passage.

- Verify Seals and Connections: Sometimes, disconnecting and reconnecting the tubes ensures a tight fit and eliminates minimal air leaks.

An efficient cooling system goes unnoticed until a sensor reminds us that without fluid, only problems circulate.

Intervene in the Pump and Internal Circuit

If the external inspection reveals no faults, the problem is likely inside the circulation circuit. The pump may have sediments, trapped air bubbles, or a dirty filter that reduce its performance.

Corrective Actions for the Internal System:- Purge the Circuit of Air: Run the purge procedure recommended by Bambu Lab to eliminate air pockets that block the pump.

- Clean or Replace the Filter: Some models include an internal filter. Removing and cleaning it can restore flow instantly.

- Evaluate the Pump Condition: In persistent cases, the circulation pump may need a deep cleaning or replacement.

Maintain the System Operational

Resolving the HMS_0D00-0100-0001-0012 error requires a systematic approach: from checking the obvious (level and connections) to intervening in internal components (pump and filters). Addressing this alert in time not only resumes printing but also protects the investment in the machine by avoiding heat damage. Keeping the cooling circuit clean and air-free is key for long and reliable prints. ✅