The Teradyne UltraFLEXplus System Tests AI Chips

In semiconductor manufacturing, an automatic test equipment (ATE) system is indispensable equipment. The Teradyne UltraFLEXplus platform stands out as an advanced solution in this field. Its main mission is to electrically verify each artificial intelligence integrated circuit before it leaves the plant. These systems operate autonomously and can evaluate thousands of connections and functions in just seconds, ensuring that no faulty chip is shipped to the end user. 🔬

The Process to Validate Each Chip

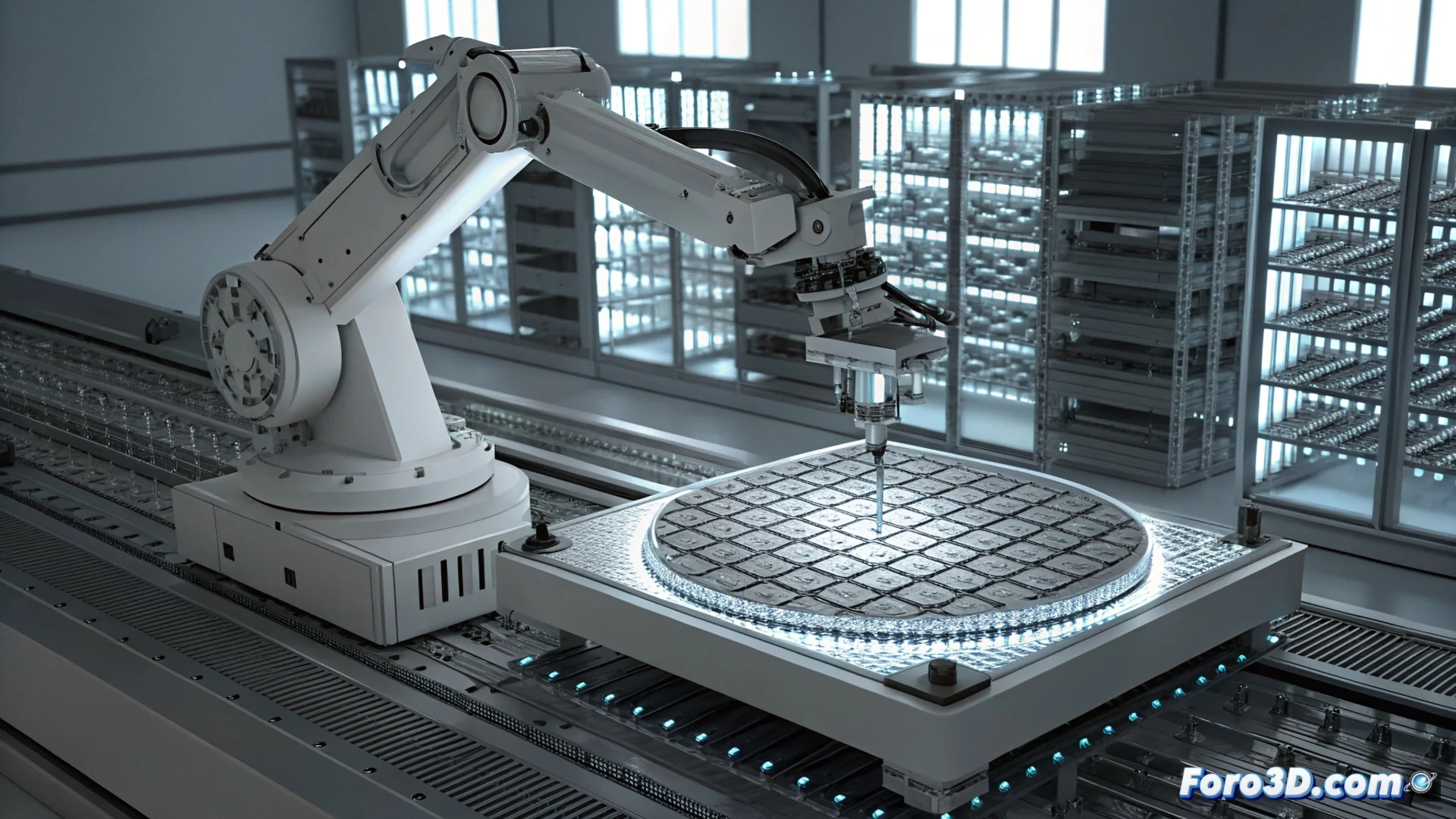

The system manipulates the devices using a high-precision robotic arm. Each chip is placed in a special socket that connects to its hundreds or thousands of pins. Subsequently, the tester's hardware applies specific patterns of electrical signals and measures how the circuit responds. It compares this data with the expected values for a functional component. If any measurement deviates, the unit is classified as defective. This process covers everything from basic current and voltage parameters to complex logic and speed tests.

Key Stages of Testing:- Manipulation and Contact: A robot places the chip in a specialized socket to make electrical connection.

- Application and Measurement: Signal patterns are sent and the device's responses are captured.

- Analysis and Decision: Results are compared to an ideal pattern; failing units are discarded.

This is the last filter before packaging a chip. Failing here means wasting all the silicon, design, and manufacturing process.

The Modular Architecture That Powers the Platform

The UltraFLEXplus platform employs a VXI-based modular architecture. This allows the equipment to be configured with different types of instrumentation cards, depending on what needs to be tested. For AI circuits, it typically integrates precision measurement source modules, high-speed digital pattern generators, and mixed-signal analyzers. Its software manages the entire flow, from loading test programs to generating final reports. The ability to run tests in parallel at multiple sites is essential to maintain high throughput in the production line.

Main Components of the System:- VXI Structure: Modular backplane that allows customization of the tester's instrumentation.

- Specialized Instrumentation: Modules for precise measurement, pattern generation, and mixed-signal analysis.

- Control Software: Manages test sequences, data handling, and report generation.

The Critical Importance in the Production Chain

The system acts as the final guardian of quality. The pressure is enormous, as an error in this phase represents the total loss of the silicon's value and all the design and manufacturing work. However, the equipment doesn't falter; its function is to identify and clearly mark what doesn't meet standards. This rigorous validation is what ensures the reliability and performance of the artificial intelligence chips that power advanced technologies. ⚙️