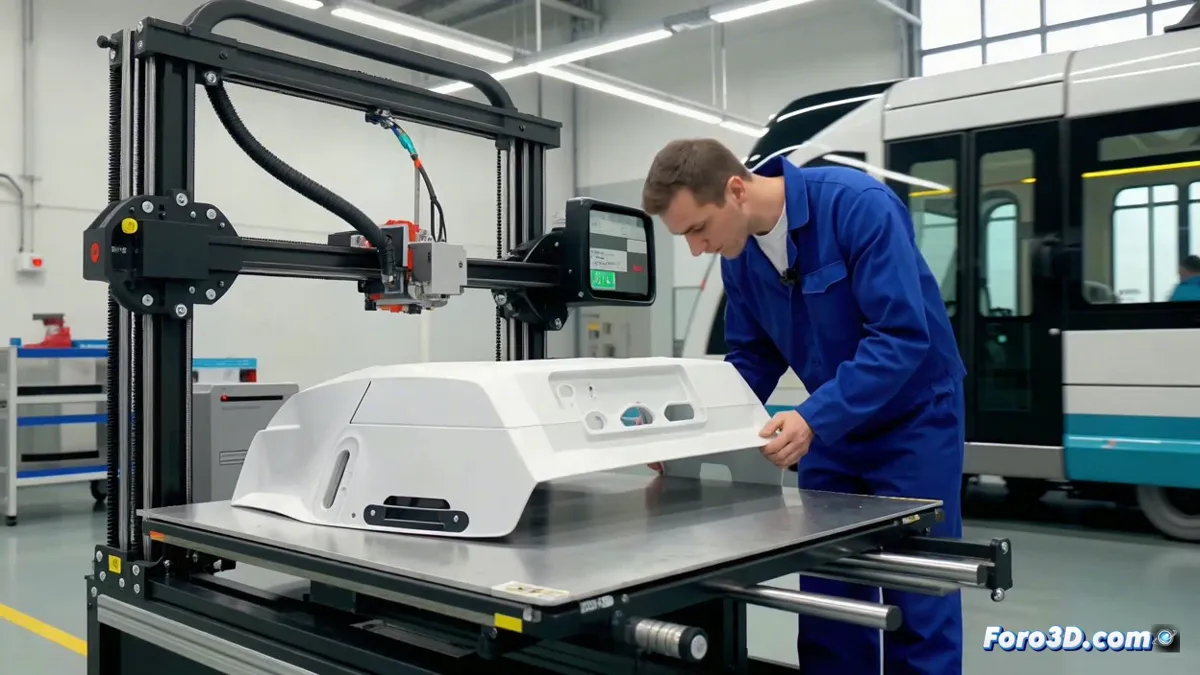

Siemens Uses 3D Printing for On-Demand Tram Spare Parts

Siemens' mobility division has integrated additive manufacturing into its maintenance strategy. The goal is to produce specific components for trams, such as rearview mirror housings or buttons, right at the moment an operator requests them. This approach prevents fleets from being out of service for long periods and reduces dependence on massive inventories or external suppliers. The technology serves as an agile solution for vehicles designed to last decades 🚋.

Transforming Spare Parts Logistics

The traditional model of storing thousands of physical parts, many for obsolete models, is replaced by a digital system. Siemens stores design files and, when a need arises, prints the part in a production center near the customer. This shortens delivery times from weeks to just days. Additionally, storage costs for stock are eliminated, and plastic components are prevented from degrading unused. The flexibility of the digital process allows redesigning or adapting a part to improve its function without creating new physical tools.

Key advantages of the on-demand system:- Reduce inventories: No need to store physical parts, only their digital files.

- Speed up delivery: Lead times go from weekly to a matter of days.

- Avoid obsolescence: Digital designs can be updated for old models.

Additive manufacturing changes the way spare parts are managed, prioritizing digital agility over physical stock.

Ensuring Quality and Durability in Public Transport

For these parts to be used in such a demanding environment, materials and processes must meet strict standards. Siemens uses high-performance polymers and printing parameters that ensure the necessary resistance to mechanical stress, weather, and intensive use. Each produced component complies with the safety and quality regulations of the railway sector. Dimensional precision is fundamental; a button or cover must fit and function exactly like the original part for years.

Critical aspects in production:- Resistant materials: Special polymers that withstand extreme conditions.

- Dimensional precision: Each part must fit perfectly in the assembly.

- Compliance with regulations: All parts pass railway quality controls.

A More Agile Future for Maintenance

This application of industrial 3D printing demonstrates its value beyond prototyping. For Siemens, it means ensuring operational continuity for its trams with a simplified and reactive supply chain. The next time a tram experiences a minor delay, it might simply be waiting for the 3D-printed button that allows the driver to close the doors, an everyday example of how this technology efficiently solves complex logistical problems 🔧.