Salamanca Researchers Manufacture Customized Prostheses with 3D Printing

A group from the University of Salamanca, integrated into the ATILA initiative, is producing hip and knee implants completely tailored to each patient using additive manufacturing techniques. This methodology promises to revolutionize orthopedic surgery by offering unique solutions. 🔬

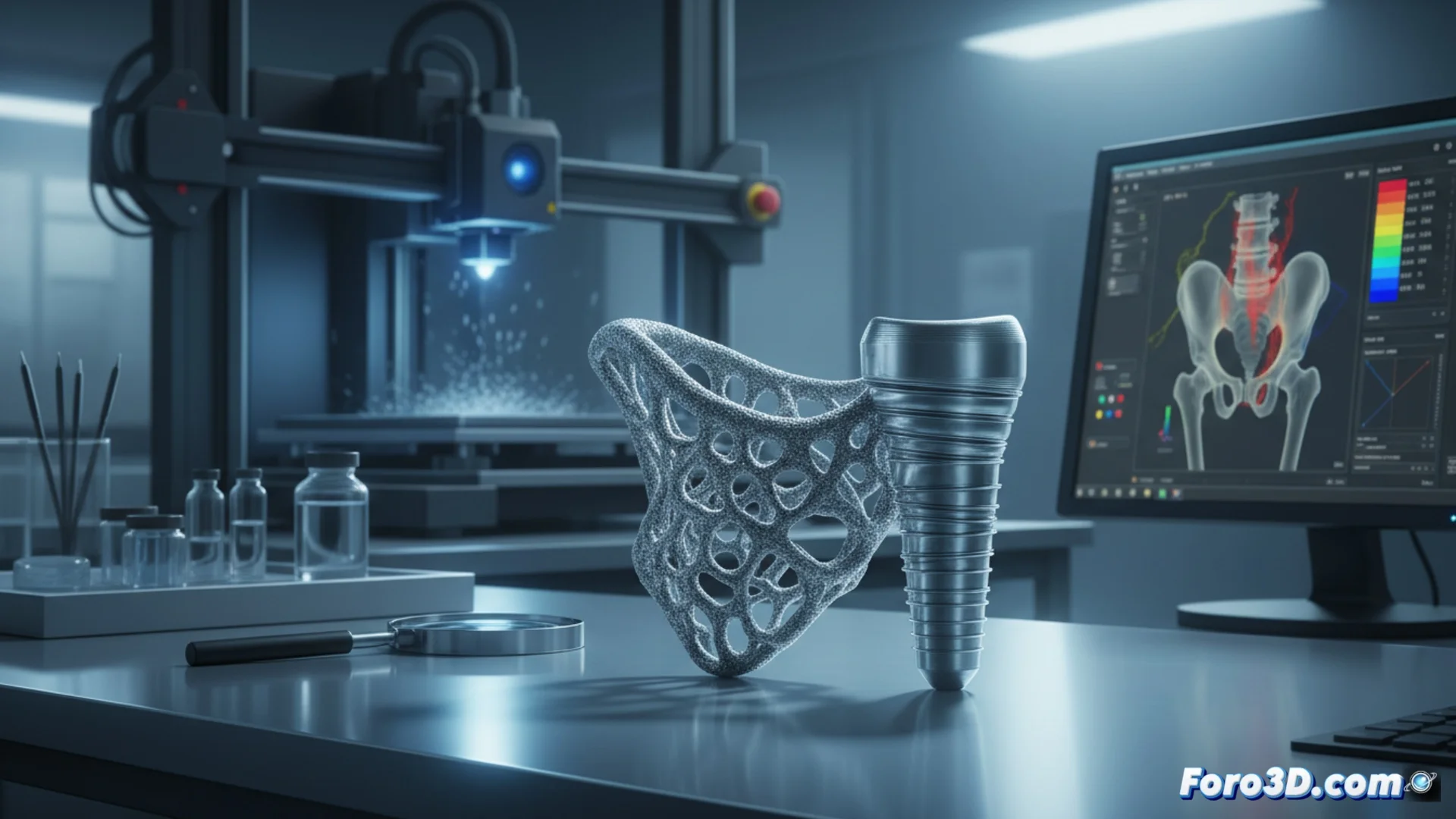

The Technology Behind Custom Implants

To manufacture these parts, the team uses an advanced process known as DED-LB/M (Directed Energy Deposition on Powder Bed). This system melts and deposits material layer by layer with a high-precision laser beam. The chosen material is titanium alloy Ti6Al4V ELI, recognized for its excellent biocompatibility and ability to integrate with human bone tissue.

Key Phases of the Manufacturing Process:- Custom Design: The prosthesis is digitally modeled to match the patient's anatomy exactly.

- Simulate Behavior: Before printing, software analyzes how the part will respond to mechanical forces.

- Texture the Surface: Work is done to modify the titanium surface so that the bone can adhere and grow on it more effectively.

The goal is to create implants that fit precisely and reduce the common problems of standard prostheses.

From Printing to Preclinical Validation

The first parts, or preforms, have already been manufactured and have passed the initial phase. Now, the project advances to a crucial stage of trials to verify their functionality and safety.

Ongoing Trials:- The implants are tested in animal models to directly observe the interaction between the bone and titanium.

- Evaluation of how the customized prosthesis adapts to joint function and supports movement.

- The process seeks to confirm osseointegration, that is, the solid and stable union between the implant and living bone.

The Path to Clinical Application

This research aims to pave the way for these custom implants to reach human patients. It is expected that this personalized approach will minimize misfits and rejection sometimes caused by conventional prostheses, significantly improving quality of life and postoperative outcomes. The future of orthopedics lies in adapting technology to the individual. 🦴