LACS drastically reduces manufacturing costs for aerospace parts

Researchers from the University of Cambridge have developed LACS (Laser-Assisted Cold Spray), a new technique that combines a supersonic jet of metal powder with localized laser heating. The result? An 85% reduction in helium usage, a key but costly gas in traditional cold spray processes.

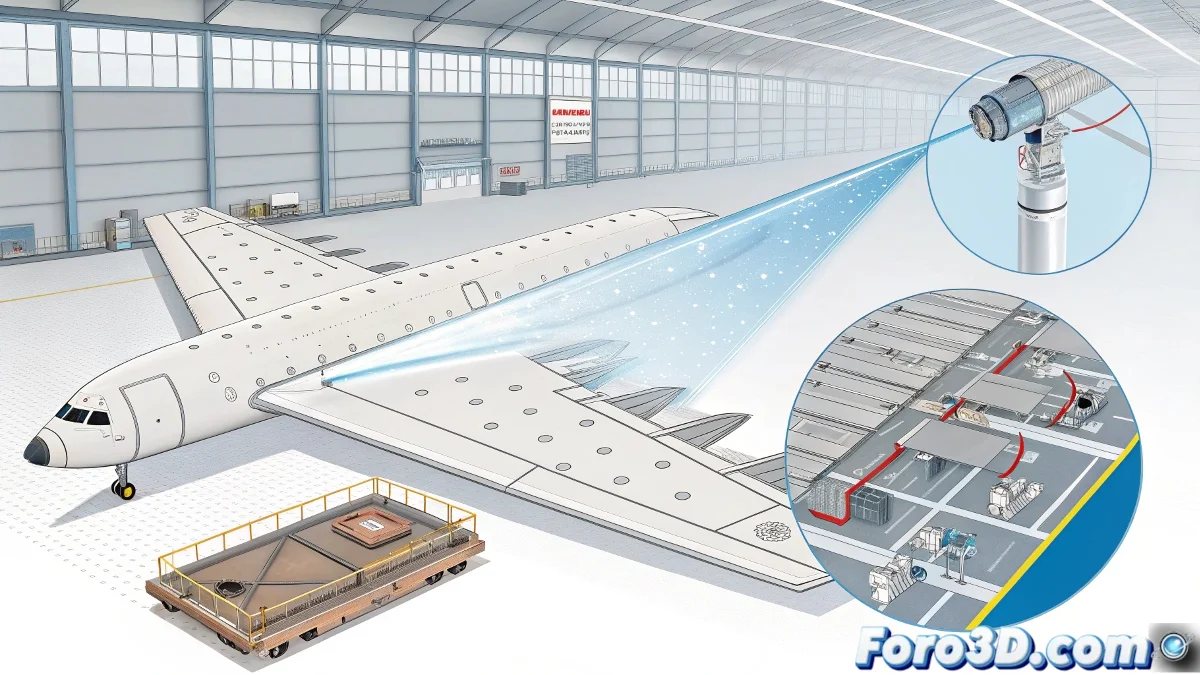

Ideal for repair and coatings in the aerospace industry

Operating at temperatures between 400-700 °C (compared to the conventional 1,200 °C), LACS can:

- Deposit up to 10 kg/hour without deforming the substrate

- Preserve the crystalline structure of delicate materials like titanium

- Repair components directly instead of storing them, reducing logistics costs

Towards 3D metal printing with LACS

Currently, LACS is mainly applied in coatings, but the team is working on controlling deposition geometry to use it in additive manufacturing of complete parts. "We have promising results," says Professor Bill O'Neill.

An innovation with significant economic and environmental impact, although it still doesn't solve what to do with all the leftover helium... beyond inflating birthday balloons.