Printing with TPU filament offers great flexibility and resistance, but it also presents technical challenges, especially on printers like the Creality Ender 3. The original design of this printer, with its Bowden extrusion system, can cause issues such as clogs, filament buckling, and inconsistent extrusion. To solve these problems, it is possible to make some key improvements to the extruder and other components.

The Cold End of the Extruder and Its Impact on TPU

One of the most common problems when printing with TPU is that the filament can buckle in the cold zone of the extruder, especially after passing through the drive gear. This phenomenon is due to the flexible nature of the material, which makes it difficult to control the flow and the pressure exerted by the extruder motor.

Extruder Improvements to Avoid Clogs

To prevent the filament from deforming in the cold end of the extruder, several solutions can be applied:

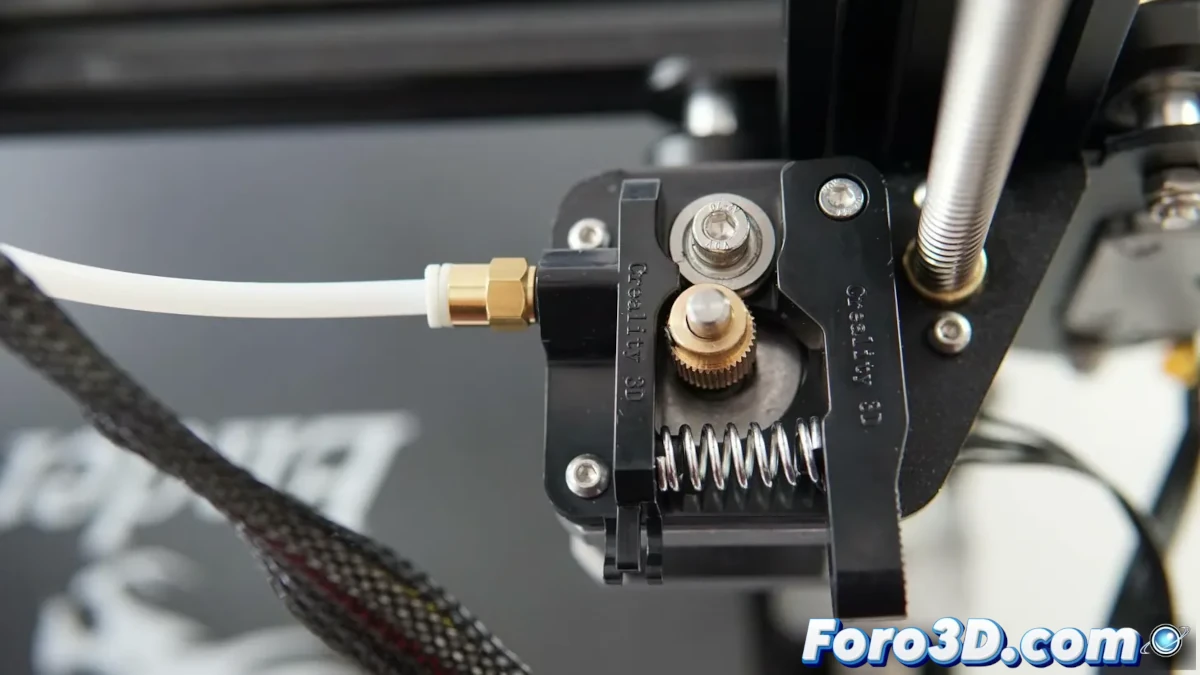

- Fully metal extruder: An extruder made entirely of metal prevents the filament from buckling inside its structure, allowing for a more stable passage.

- Modification with additional guide: Some users have developed 3D printed parts that keep the filament aligned in the extruder. An example is the improvement published on Thingiverse by user joshvv.

- Homemade solutions: Ingenious methods, such as inserting a small straw into the filament entry channel, can help keep it straight and avoid blockages.

Direct Drive Extrusion System as a Solution

The original extrusion system of the Ender 3 uses a Bowden tube, which separates the extruder motor from the hotend. This design can cause problems with flexible materials like TPU, as the filament can buckle inside the tube instead of being pushed efficiently.

Advantages of Direct Drive Extrusion

- Greater precision: By eliminating the Bowden tube, the filament is pushed directly to the hotend, reducing the possibility of buckling.

- Better grip: With a shorter path, the extruder motor can control the filament flow more efficiently.

- Fewer retractions needed: The reduced distance between the extruder and the hotend minimizes problems caused by excessive retractions.

To make this improvement, there are conversion kits that replace the Bowden system with a direct drive extruder, allowing the Ender 3 to handle TPU more easily.

The Hot End and Its Importance in TPU Printing

The hotend is another component that influences TPU printing. An inadequate design can cause clogs or temperature fluctuations that affect print quality.

Benefits of a Fully Metal Hotend

- Greater thermal stability: A fully metal hotend can reach higher temperatures more uniformly.

- Elimination of PTFE tube: In standard hotends, the PTFE tube can deform with heat and affect filament extrusion.

- Compatibility with more materials: This type of hotend allows printing other high-temperature materials besides TPU.

Upgrading the hotend not only improves TPU printing but also expands the range of materials that can be used.

The Bowden Tube and Its Influence on Extrusion

In printers with a Bowden system, the tube guides the filament from the extruder to the hotend. However, with flexible materials, this tube can be a failure point if it is not of good quality.

How to Optimize the Bowden Tube

- Use a higher quality tube: Capricorn tubes have less internal friction, facilitating filament passage.

- Reduce tube length: A shorter path minimizes the possibility of filament buckling.

- Adjust print parameters: Setting appropriate speed and temperature reduces pressure inside the tube.

"A proper setup of the extruder and hotend is key to achieving successful prints with flexible filaments like TPU."

Conclusion

TPU printing on the Ender 3 can present challenges, but with some modifications and adjustments, excellent results can be obtained. From improving the extruder and switching to a direct drive extrusion system to optimizing the hotend and Bowden tube, each improvement contributes to more stable and smooth printing. With these changes, the Ender 3 becomes a tool capable of handling flexible materials with precision.