When Additive Manufacturing and Machining Decide to Work as a Team

Hybrid Directed Energy Deposition is proving that in industrial manufacturing, just like in good marriages, the key is to complement each other rather than compete. This hybrid technology combines the best of two worlds: the creative freedom of additive manufacturing with the millimeter precision of traditional machining. 🔧 The result is a process that allows creating metal parts so complex they would make any engineer sweat, but with finishes that look like they came from high-end jewelry. Sectors like aeronautics and energy are adopting this technology for components where a microns error can cost millions, proving that sometimes, unity really makes strength.

How Does This Technological Wonder Work?

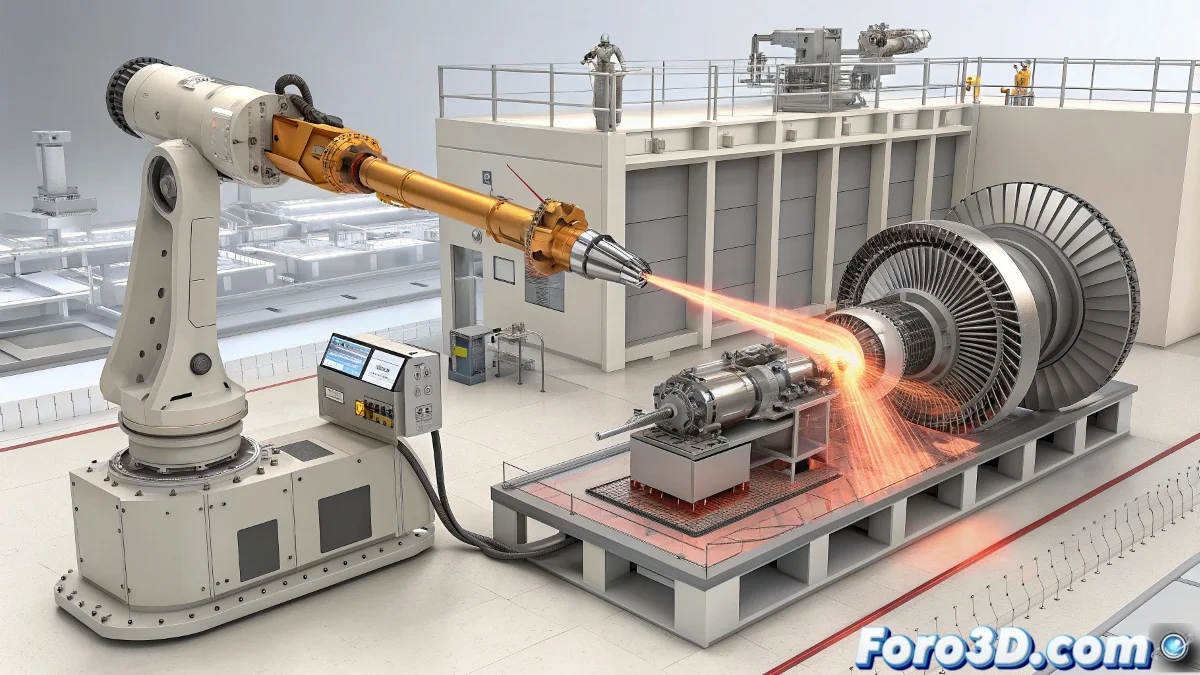

Imagine a machine that first deposits material layer by layer like a metal 3D printer, and then passes a machining head that polishes and perfects every detail in the same setup. This choreography between material addition and subtraction is what makes Hybrid DED so special. ⚙️ While the deposition process builds the overall geometry, the integrated machining takes care of correcting deviations, improving tolerances, and achieving those surface finishes that drastically reduce the need for additional post-processing. It's like having a sculptor and a polisher working in unison on the same masterpiece.

Advantages That Are Changing the Rules of the Game:- Complete integration in a single machine setup

- Impossible dimensional tolerances with purely additive methods

- Ability to repair high-value parts instead of replacing them

- Drastic reduction in total production times

Applications That Justify the Investment

In the aeronautical industry, Hybrid DED is revolutionizing the manufacturing and repair of critical components like turbine blades and complex structural elements. The ability to add material only where needed and then machine it with aerospace precision extends the useful life of parts that were previously considered unrecoverable. ✈️ In the energy sector, it is used to create and maintain reactor and wind turbine components where resistance to extreme conditions is non-negotiable. And in high-end automotive, it enables rapid prototyping and limited series production with mass production quality.

The Price Challenge: When Technology Hurts the Wallet

Not everything is good news in the world of Hybrid DED. Machines capable of performing these hybrid processes have prices that can make even the most stoic CFO cry. 💸 We're talking about investments that frequently exceed half a million euros, a significant hurdle for many SMEs in the sector. Additionally, the learning curve for operators is considerable, requiring knowledge of both additive programming and traditional CNC machining. It's like asking a chef to master both molecular gastronomy and the most classic traditions.

Current Barriers to Mass Adoption:- Prohibitive initial investment for many companies

- Lack of standardization in processes and parameters

- Shortage of operators with dual training in both technologies

- Piece size limitations depending on the available machine

Part Repair: The Secret Superpower of Hybrid DED

One of the most underestimated aspects of this technology is its ability to revive parts that would otherwise end up in the scrapyard. Heavy machinery components, worn injection molds, or even production tools can be restored by adding material exactly where needed and machining it back to its original geometry. 🔄 The potential savings are enormous, especially in industries where a single component can cost tens of thousands of euros. It's the industrial equivalent of having a team of plastic surgeons for metals instead of simply replacing entire organs.

Hybrid DED does not seek to replace existing technologies, but to create an ecosystem where manufacturing and finishing coexist in perfect harmony

The Future: Towards Standardization and Accessibility

Like any emerging technology, Hybrid DED needs to overcome its current challenges to reach its full potential. Process standardization, the development of more intuitive software, and equipment cost reduction will be crucial for its mass adoption. 📈 Researchers are working on solutions that simplify programming and reduce the learning curve, while machine manufacturers compete to offer more affordable and versatile systems. The ultimate goal is to democratize a technology that currently seems reserved for industrial giants with unlimited budgets.

Conclusion: Revolution or Natural Evolution?

Hybrid Directed Energy Deposition represents less a disruptive revolution and more the logical evolution of digital manufacturing towards integration and efficiency. Its true value is not in replacing existing methods, but in complementing them intelligently to overcome technical limitations. 🏭 In the end, as engineers working with this technology rightly point out, parts produced with Hybrid DED have such perfect finishes that they make the designers' own resumes look like mere preliminary drafts. And in a world where precision is synonymous with quality, that's a compliment hard to beat. 😄