How to Control Heat to Print PEEK, PEKK, and ULTEM Correctly

Processing advanced materials like PEEK, PEKK, or Ultem in FDM 3D printing goes beyond just melting the filament. The real challenge is managing the heat so that the polymer develops its crystalline microstructure, which defines its mechanical strength and thermal stability. A common mistake is cooling the part too quickly, which generates fragility and deformations. 🔥

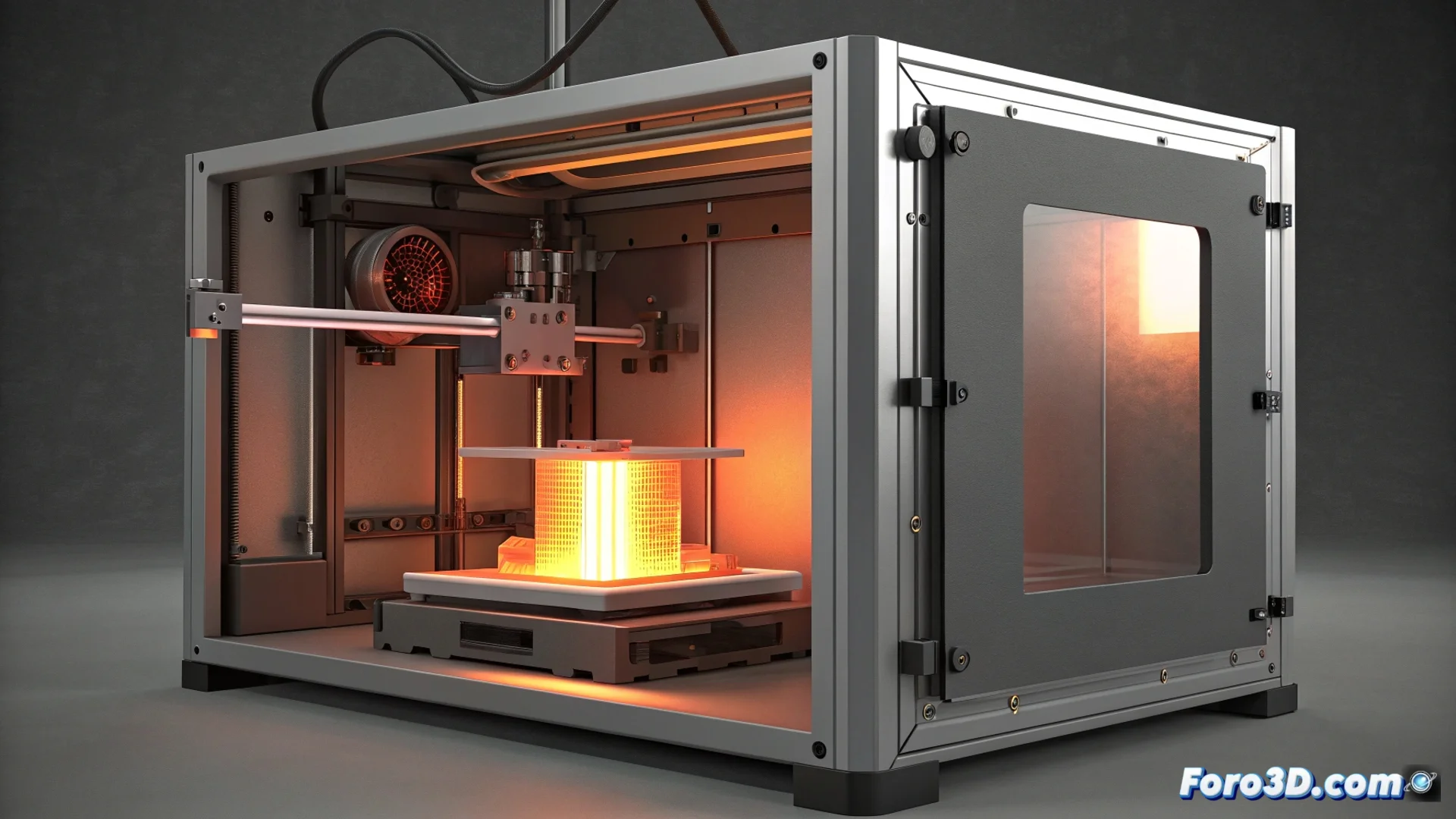

The Critical Role of the Hot Build Chamber

The main function of a hot chamber is to create a stable and elevated thermal environment, generally between 120°C and 180°C. This temperature not only prevents the material from cooling upon deposition but also allows the long polymeric chains to organize slowly and orderly as they solidify. If the chamber is cold, the material vitrifies forming a weak amorphous structure.

Key Factors for an Effective Chamber:- Stable Temperature: Fluctuations harm the crystallization process. It is vital to check that the heaters, insulators, and sensors work precisely.

- Heat Uniformity: The heat must be distributed homogeneously throughout the build volume so that the part crystallizes consistently.

- Robust Insulation: A well-sealed and insulated chamber conserves energy, maintains temperature, and protects from cooling by air currents.

If your PEEK part breaks like a cookie, it might not be the material, but that you're treating it like PLA and giving it a cold shock from which it doesn't recover.

Managing the Cooling Phase After Printing

Finishing the layer work does not mean the process is over. Here begins an equally crucial stage: cooling the part in a controlled manner. Turning off the machine and opening the chamber abruptly causes a thermal shock that ruins the crystallization and generates internal stresses.

Strategies for Proper Cooling:- Cooling in a Closed Chamber: The safest is to let the part cool slowly inside the turned-off but sealed chamber, allowing the temperature to drop naturally and gradually.

- Programmed Cooling Profiles: Some advanced firmwares allow programming a temperature descent ramp for the chamber after printing, optimizing the process.