How the GOM ATOS System Works for 3D Scanning

Contactless measurement technology evolves with systems like GOM ATOS. This three-dimensional optical scanner uses a method that does not touch the part, capturing millions of coordinates synchronously to represent the actual surface with high fidelity. 🎯

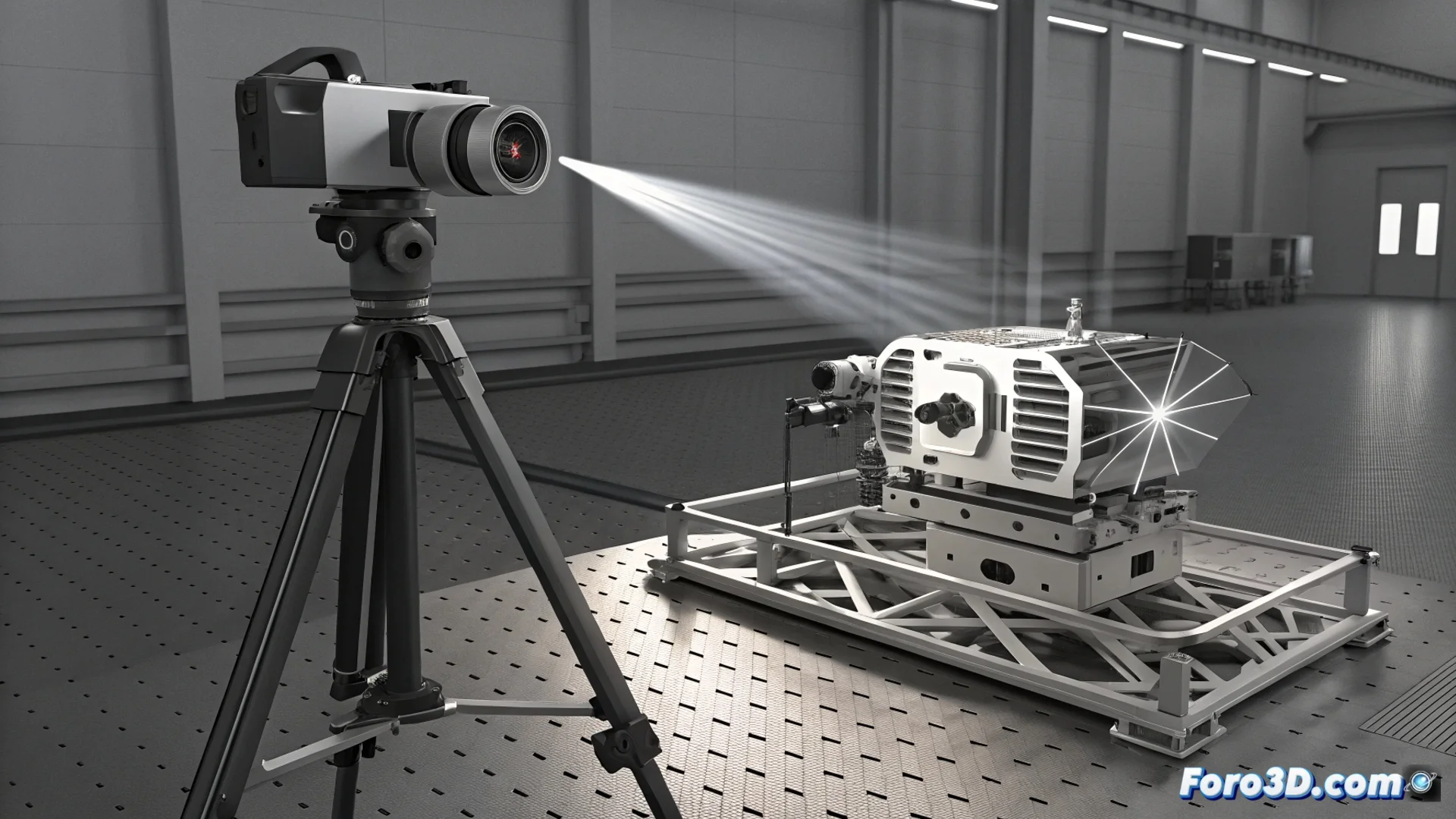

The Principle of Fringe Projection

The core of the system is based on projecting structured light patterns. A digital projector emits light fringes onto the object, while two high-resolution cameras, positioned at a precise angle, observe how these patterns deform on the surface. Specialized software calculates the 3D position of each point from these deformations.

Step-by-Step Capture Process:- The projector illuminates the part with a light fringe pattern.

- Two cameras capture the pattern deformation from different angles.

- The software processes data from both cameras to triangulate the position of each measured point.

- The process is repeated from multiple positions to digitize the entire geometry of the object.

The key advantage is inspecting every point on the surface, not just specific locations.

Full-Field Analysis and CAD Comparison

After capturing the data, the system generates a dense and accurate point cloud. This cloud enables comprehensive analysis, where each scanned point can be compared with the theoretical CAD model of the part. The result is visual deviation maps, usually in color, that accurately indicate the differences between the actual part and its nominal design.

Advanced Inspection Capabilities:- Detects variations and defects across the entire surface, even those imperceptible to the human eye.

- Generates detailed graphical reports with color maps showing deviations.

- Provides quantitative data for quality control, reverse engineering, or prototyping.

Precision and Practical Applications

The extreme precision of GOM ATOS makes it a vital tool in industries like automotive or aerospace. Its ability to detect minimal discrepancies ensures that components meet the most demanding design specifications. It is a technology that transforms how we measure and understand physical objects in the digital environment. 🔍