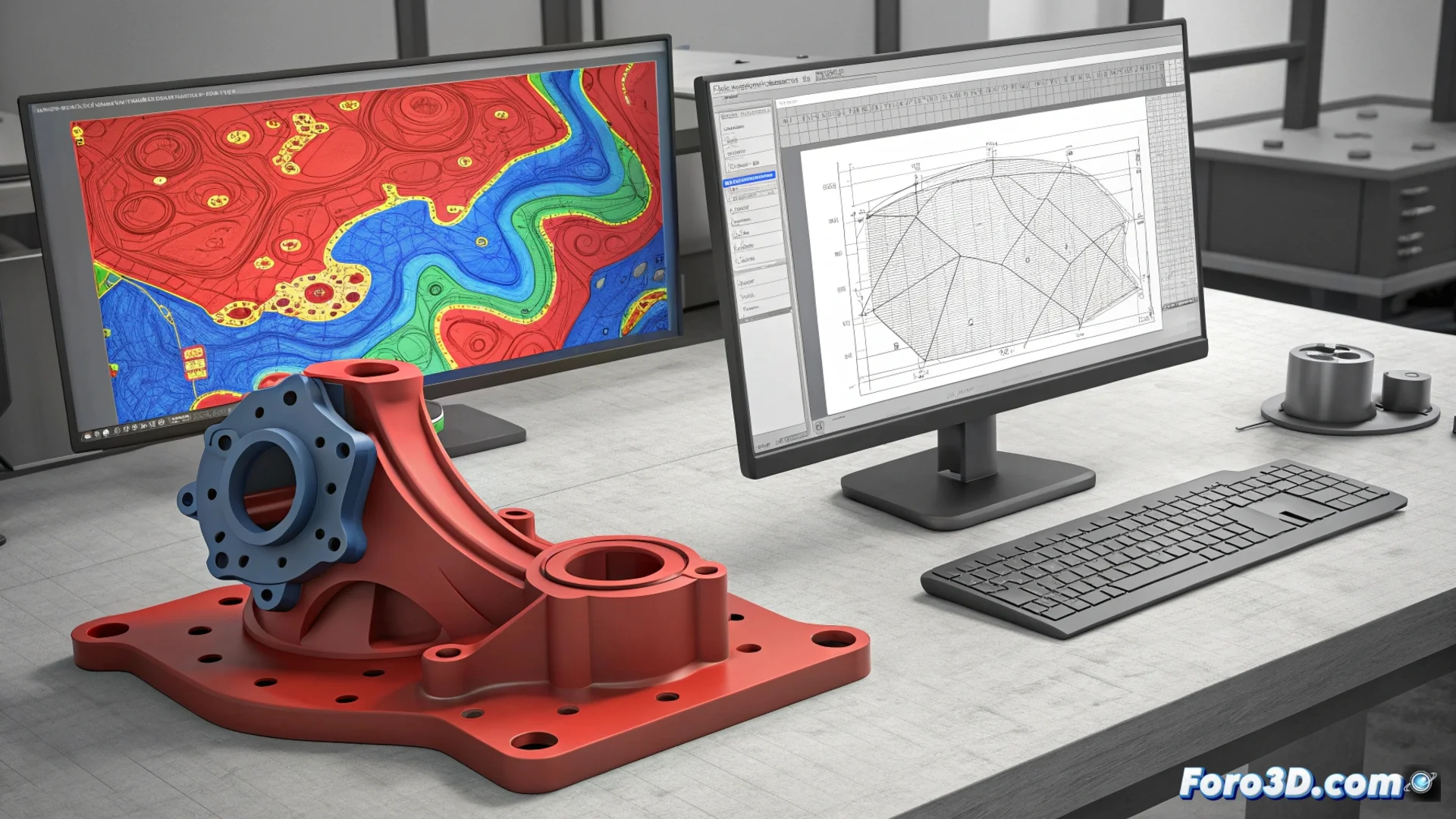

GOM Inspect: Analyze Physical Parts by Comparing Them with CAD Models

In the field of quality control and digital metrology, GOM Inspect stands out as an essential tool. This software takes data from a 3D scanner of a real part and automatically compares it with its theoretical CAD model. The result is an objective evaluation of the component's geometry, generating visual maps that detail any discrepancies. 🧐

Workflow for Inspecting a Component

The procedure begins when the user loads two elements: the nominal CAD and the point cloud obtained from scanning the manufactured part. Using advanced algorithms, the software aligns both datasets in the same coordinate space. It then calculates the distance between each scanned point and the theoretical CAD surface. This information is translated into a visual deviation map, where a color scale indicates the differences.

Key Steps in the Process:- Import Data: Load the CAD file and the 3D scanner data.

- Align Geometries: Algorithms overlay the real part with the ideal model.

- Calculate Deviations: The system measures distances between surfaces point by point.

The software's precision does not forgive process failures, transforming manufacturing errors into an interpretable rainbow of data.

Interpreting the Color Deviation Map

The generated map is an immediate visual guide. Cool colors like blue typically indicate areas with excess material. Conversely, warm colors like red highlight areas with material shortage. The green shade usually represents the acceptable tolerance band, where deviation is minimal. This visualization allows identifying manufacturing issues at a glance and generating detailed reports for documentation.

Meaning of the Color Palette:- Blue: Indicates that the real part has more material than the CAD model (positive deviation).

- Red: Shows that the part lacks material compared to the theoretical design (negative deviation).

- Green: Represents that the part is within the specified tolerance limits.

Impact on Production Control

Beyond creating a colorful graphic, the value of GOM Inspect lies in its ability to quantify deviations with accuracy. It provides a solid metric database for optimizing manufacturing processes, reducing scrap, and ensuring components meet design specifications. The final challenge is to use this precise information to communicate effectively and correct inefficiencies in the production line. 🛠️