General Motors Investigates 3D-Printed Battery Housings for Its Ultium Platform

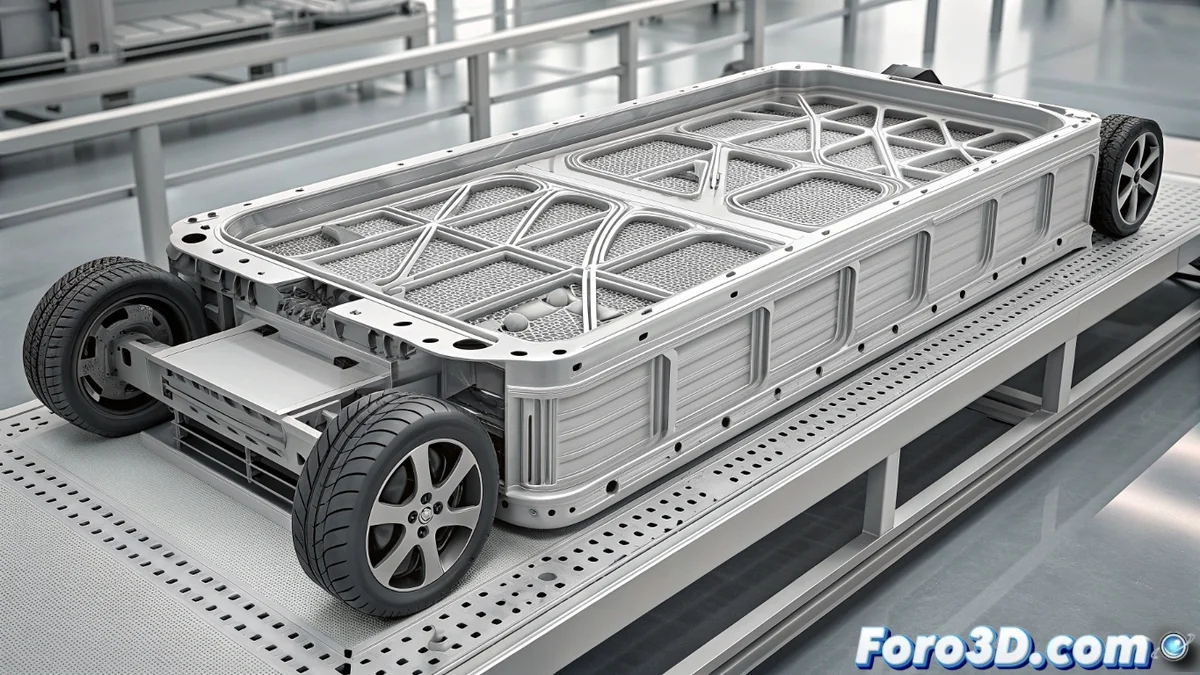

The automotive company General Motors is advancing in the use of additive manufacturing to create critical components in its transition toward electrification. The current focus is on developing housings for the battery packs of its Ultium architecture, seeking to integrate multiple functions into a single 3D-printed piece. This approach represents a significant shift in how structural elements of electric vehicles are designed and produced. 🔋

Integrating Structure and Cooling into a Single Piece

GM's project consists of consolidating the load-bearing structure of the battery pack and the thermal management system into a single monolithic component. Metal 3D printing enables the creation of labyrinthine internal geometries that are unfeasible with traditional casting or machining methods. This is not just a design exercise, but an effort to redefine the efficiency of complex assemblies.

Key Advantages of Additive Design:- Part Consolidation: Replacing multiple welded or joined components with a single printed piece increases rigidity and reduces potential failure points.

- Total Geometric Freedom: Engineers can distribute material only where strength is needed, lightening the total weight without compromising structural safety.

- Function Integration: Coolant fluid channels are designed and manufactured directly within the housing walls, optimizing heat transfer from the cells.

Perhaps the biggest challenge is not printing the piece, but convincing the entire team that such an organic and complex design is not a failed prototype, but the final solution.

A Critical Component for Safety and Performance

In an electric vehicle, the battery housing is a primary structural element. It must protect the cells in collisions and withstand the constant dynamic loads of driving. Additive manufacturing allows the use of specialized aluminum alloys to achieve the best strength-to-weight and durability ratio. This method also enables maximizing internal space to house more cells within the same external vehicle dimensions, increasing range. ⚡

Materials and Performance Objectives:- Lightweight Alloys: Materials like aluminum are prioritized for their combination of low density and high mechanical strength.

- Optimized Thermal Management: Integrated cooling channels help maintain cells within their ideal temperature range, which is crucial for battery performance, lifespan, and safety.

- Rigorous Validation: Printed prototypes must pass exhaustive impact, fatigue, and sealing tests to meet the automotive industry's strict standards.

The Path from Prototype to Production

GM is in the research and development phase of functional prototypes. The leap from this R&D stage to implementation in large-scale production lines presents logistical and cost challenges. However, the potential to simplify assemblies, reduce vehicle weight, and improve battery performance makes this technology a strategic bet for the future of electric mobility. Success will depend on scaling the process while maintaining the required quality and reliability. 🚗