When Metallic Particles Fly at Supersonic Speeds

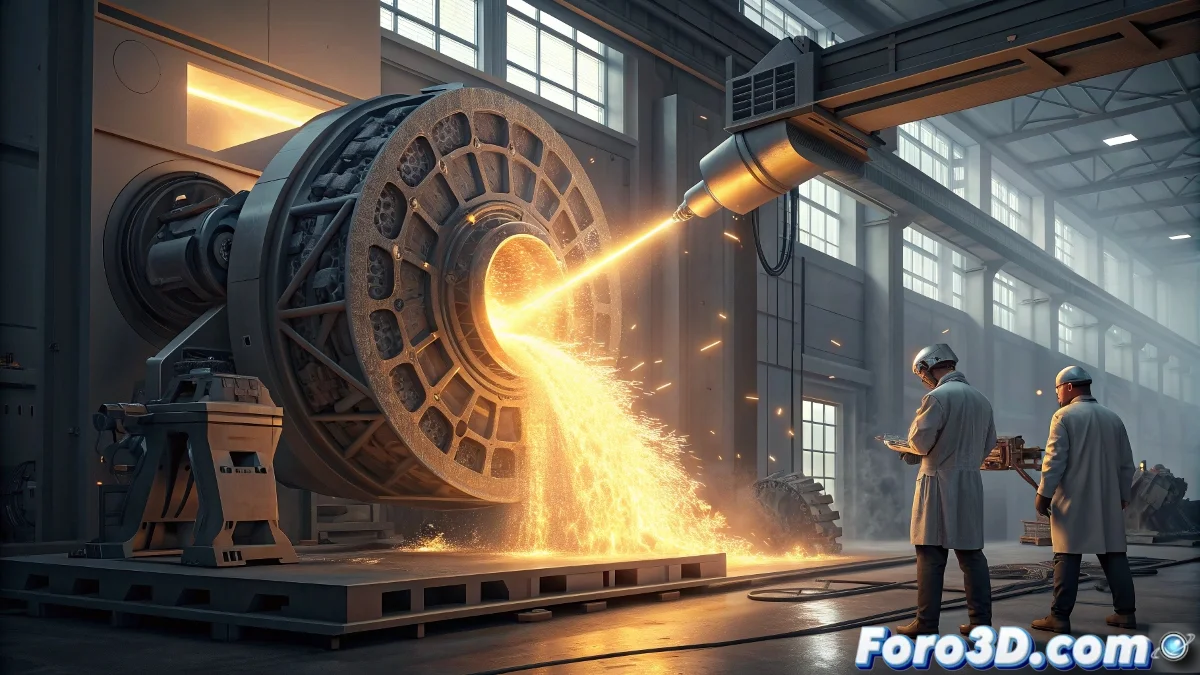

Florida International University is positioning itself as a pioneering institution in large-scale Cold Spray application research, a manufacturing and repair technology that challenges conventional intuition. Unlike traditional thermal processes, Cold Spray uses compressed gas to accelerate metallic particles to supersonic speeds that, upon impacting a substrate, plastically deform and mechanically bond without melting. This unique approach preserves the base material properties and avoids issues associated with intense thermal cycles.

What makes this research particularly valuable is its focus on industrial-scale applications, taking Cold Spray beyond the laboratory into real-world implementations. Conventional systems typically handle small or medium components, but FIU is developing capabilities to work with large structures such as aerospace components, marine infrastructure, and energy equipment. This scaling requires overcoming significant challenges in deposition consistency, quality control, and process efficiency.

Potential Applications of Large-Scale Cold Spray

- Repair of aerospace components without affecting base material properties

- Regeneration of worn surfaces in turbines and industrial machinery

- Manufacturing of metallic composites with customized gradual properties

- Corrosion protection in marine and offshore infrastructure

The Science Behind the Cold Process

The fundamental mechanism of Cold Spray is fascinatingly counterintuitive: instead of melting the material, it leverages adiabatic plastic deformation that occurs when particles impact at critical velocities. This deformation generates sufficient localized heat to create metallurgical bonding without reaching the material's melting temperature. The result is coatings with minimal porosity, excellent adhesion, and mechanical properties that often surpass those of traditional thermal processes.

Sometimes the best way to join metals is to hit them hard enough

FIU's research focuses on optimizing parameters for different material combinations and complex geometries. Variables such as gas temperature, pressure, spray distance, and particle characteristics must be meticulously adjusted for each specific application. The development of real-time monitoring systems allows controlling deposit quality during the process, detecting anomalies before they compromise the final component's integrity.

Advantages Over Traditional Methods

- Microstructural preservation of the base material without heat-affected zone

- Environmentally friendly process without toxic fumes or UV radiation

- High material efficiency with minimal waste and recycling possibility

- Material versatility including reactive metals like magnesium and titanium

The potential of Cold Spray extends beyond simple repair. The technology enables creating advanced functionalities such as conductive coatings, surfaces with controlled friction coefficients, and even multimaterial structures with gradual transitions. For industries like aerospace, where every kilogram counts, the ability to repair expensive components instead of replacing them represents substantial savings and reduced downtime.

Those who thought metal manufacturing and repair would always require intense heat will likely be surprised to discover what can be achieved when particles travel faster than sound ⚡