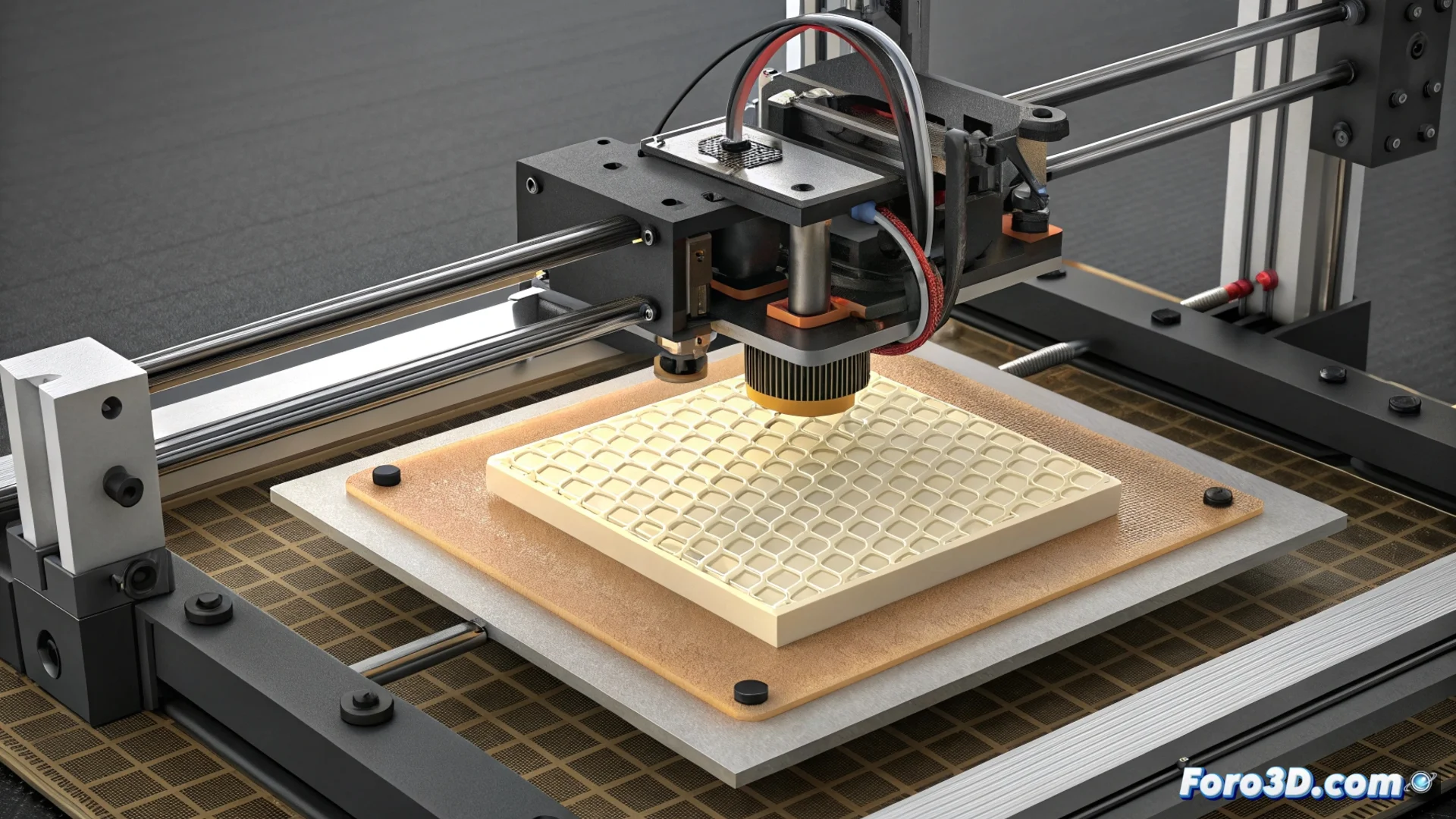

Fixing Pillowing on 3D Printing Surfaces

A common defect in FDM 3D printing is pillowing or pillowing. This problem arises because the layers forming the top face of the object lack adequate support from below. 🛠️

Why does the surface sink?

The internal infill, when set to a low percentage, leaves large spaces. When the nozzle extrudes molten plastic to create the top layer, this material curves or sags into those gaps as it cools, generating a bumpy and irregular texture.

Key factors causing the defect:- An insufficient number of solid top layers in the slicer settings.

- A infill density that is too low, which does not support the part's roof.

- Rapid cooling that contracts the plastic over a weak structure.

It looks like the printer decides to add an unwanted special texture to the top of your model.

Adjust the top layers

The most effective strategy to prevent the plastic from sinking is to increase the solid top layers. By adding more layers, stresses are distributed and a more rigid base is built. 🏗️

How to configure correctly:- Program at least four or five top layers in your slicing software.

- This allows the material to cool more gradually and evenly over the infill.

- The result is a noticeably smoother and flatter final surface.

Reinforce internal support

Modifying the infill pattern and density provides more direct support. A higher percentage reduces the size of the gaps under the surface.

Recommended parameters to optimize:- Increase the infill percentage to values like 25% or 30%.

- This generates a denser and more continuous support mesh that prevents the plastic from curving.

- For the best results, combine denser infill with more solid top layers.

Final tip for perfect parts

If you're looking for impeccable top surfaces, don't underestimate these two