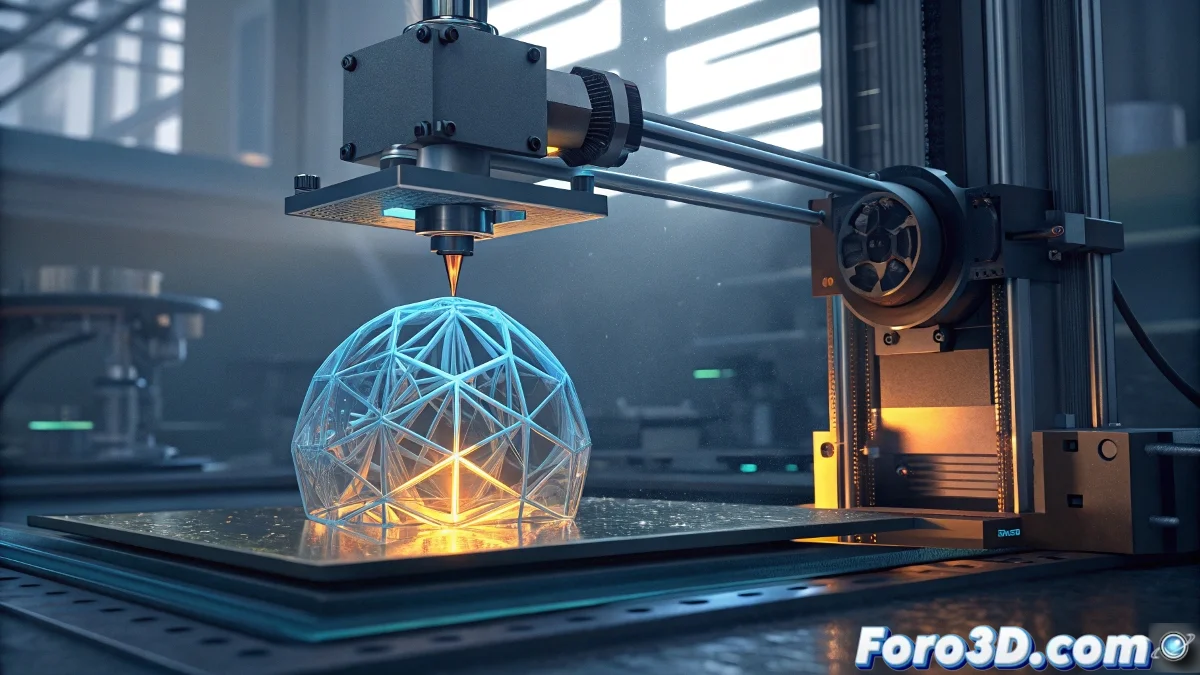

The Swiss Revolution in Three-Dimensional Printing

The École Polytechnique Fédérale de Lausanne, worldwide known as EPFL, has achieved a significant breakthrough in the field of additive manufacturing. Its new 3D printing method solves one of the most persistent problems in the industry: porosity in metal and ceramic parts. This innovation allows creating objects with a density close to the material's theoretical value, overcoming the limitations that have previously affected the mechanical properties of printed parts.

The technique developed by the Swiss researchers stands out for its focus on the post-printing densification process. While conventional methods struggle against pore formation during manufacturing, the EPFL team has optimized sintering parameters and developed a specific thermal treatment that virtually eliminates all residual porosity. The result is parts with mechanical properties equivalent to those manufactured by traditional methods.

Technical Advantages of the New Method

- Superior density over 99.5% of the material's theoretical value

- Mechanical properties equivalent to molded or forged parts

- Compatibility with multiple metal alloys and ceramic compositions

- Industrial scalability for series production of critical components

The Secret Behind Perfect Densification

The innovative process begins with conventional printing using additive manufacturing, but incorporates a crucial post-processing stage where the magic happens. The researchers discovered that by precisely controlling the sintering atmosphere and applying specific thermal cycles, they could achieve the necessary atomic migration to close all micropores. This densification does not compromise the complex geometry that 3D printing enables.

Perfect density is no longer an unattainable ideal in 3D printing

The key lies in understanding the kinetics of atomic diffusion processes during thermal treatment. EPFL scientists have developed computational models that predict exactly how temperature cycles should be applied for each specific material. This customization of the process ensures optimal results regardless of the alloy or ceramic composition used.

Potential Industrial Applications

- Aerospace components that require maximum strength and density

- Medical implants with improved mechanical properties and biocompatibility

- Cutting tools and components for the manufacturing industry

- Electronic devices that demand perfect hermetic sealing

The implications of this technology could transform numerous industrial sectors where porosity has been the Achilles' heel of 3D printing. From high-temperature turbines to prostheses that must withstand cyclic loads, the applications are as diverse as they are promising. The method also maintains the design freedom that characterizes additive manufacturing, allowing intricate geometries impossible to achieve with subtractive methods.

Those who still see 3D printing as a technology for prototypes might want to reconsider their prejudices 🔧