Process for Electrifying a Classic Vehicle and 3D Modeling of the Bodywork

The process of electrifying a classic vehicle not only involves adapting its mechanical and electrical systems, but also making use of advanced 3D modeling tools to ensure the proper integration of electrical and propulsion components. A crucial aspect in this type of project is the creation of a technical report that can be presented in competitions or when applying for subsidies. Below, the steps and recommendations for carrying out this type of reverse engineering using 3D modeling technology will be explored.

The Challenge of 3D Modeling for Classic Vehicles

One of the first stages in electrifying a classic vehicle is the analysis of the chassis, dimensions, and overall structure of the vehicle. In this case, technology plays a fundamental role, and the use of a 3D scanner is essential to obtain an accurate representation of the vehicle's bodywork. 3D scanners generate millions of triangular faces (also known as STL mesh faces) that represent the surface of the scanned object. However, this file may contain some imperfections that must be corrected to achieve a more accurate and usable model.

Converting the Mesh to a Solid Model

Once the file is in STL format, the next challenge is to convert the mesh into a solid model suitable for the vehicle's functional design. To do this, there are several methods that allow transforming a mesh into a three-dimensional solid model. However, precision is key in this step, as small details can affect the final result.

The process begins with mesh optimization. This includes reducing faces, smoothing surfaces, and eliminating imperfections. Tools like MeshMixer or Blender 3 are ideal for cleaning the mesh and preparing the STL file for import into Fusion 360 (currently known simply as Fusion).

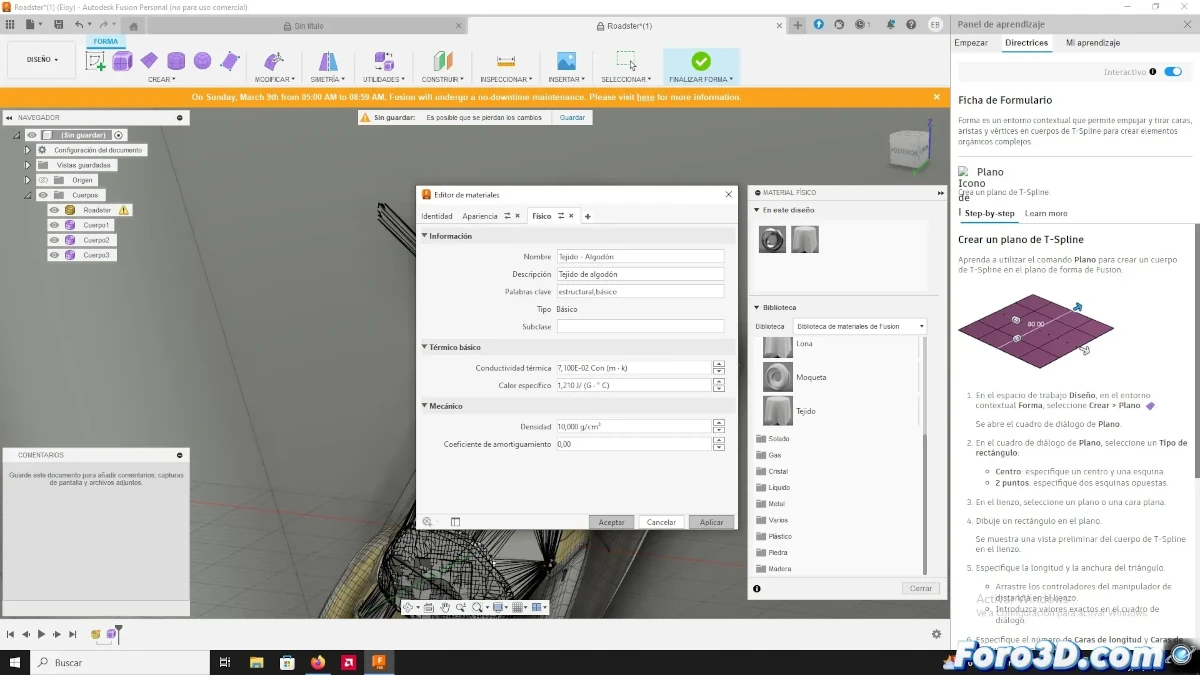

Once the mesh has been cleaned and the file optimized, it can be imported into Fusion 360 to continue creating the solid model. This is where the "create form from mesh" tool comes into play. This process can be complicated, as it is necessary to handle the mesh topology to ensure that all faces are correctly defined.

Recommendations for Modeling the Bodywork and Components

In this type of project, it is common to start by modeling the vehicle's bodywork, as it is the largest and most complex component. The idea is to give the bodywork an appropriate thickness, which involves working in millimeters to ensure precision in the dimensions. As modeling progresses, other techniques can be applied, such as creating components by revolution, which is especially useful for modeling parts like wheels or rims.

- STL file optimization: Reduce the number of faces and smooth the mesh.

- Mesh cleaning: Use tools like MeshMixer or Blender 3 to improve the file quality.

- Solid model creation: Use Fusion 360 to convert the mesh into a three-dimensional solid model.

- Documentation: Keep a detailed record of each step of the process for the technical report.

The Role of Reverse Engineering in Electrification

Reverse engineering is a key methodology when working with classic vehicles. By performing a 3D scan of the bodywork and other vehicle components, an accurate digital representation is obtained that can be manipulated to design the new parts or adaptations necessary for electrification. This process requires a meticulous approach to ensure that all modifications are compatible with the original chassis, without losing precision or functionality.

“The key to this type of project lies in optimizing each step of the process, from the initial scan to the creation of a solid model. Documenting each advance is crucial to maintaining control over the modifications made.”

As for recommendations for those carrying out similar projects, it is ideal to start with the right tools, such as a good 3D scanner, and then use specialized modeling software like Autodesk Fusion and SolidWorks to make functional adjustments. However, it is also important not to lose sight of precision in modeling and the quality of the files being worked with.

Conclusion: Preparation and Precision in Vehicle Electrification

Electrifying a classic vehicle is not only a technical challenge, but also a creative exercise. By combining reverse engineering, 3D modeling, and a precise approach to documentation, a successful project can be created that is not only functional but also innovative. As technology continues to advance, more tools and resources will be available to facilitate these projects, offering new possibilities to those who venture to transform classic vehicles into electric cars.