Continuum Powders Launches Copper and Nickel Alloys for Additive Manufacturing

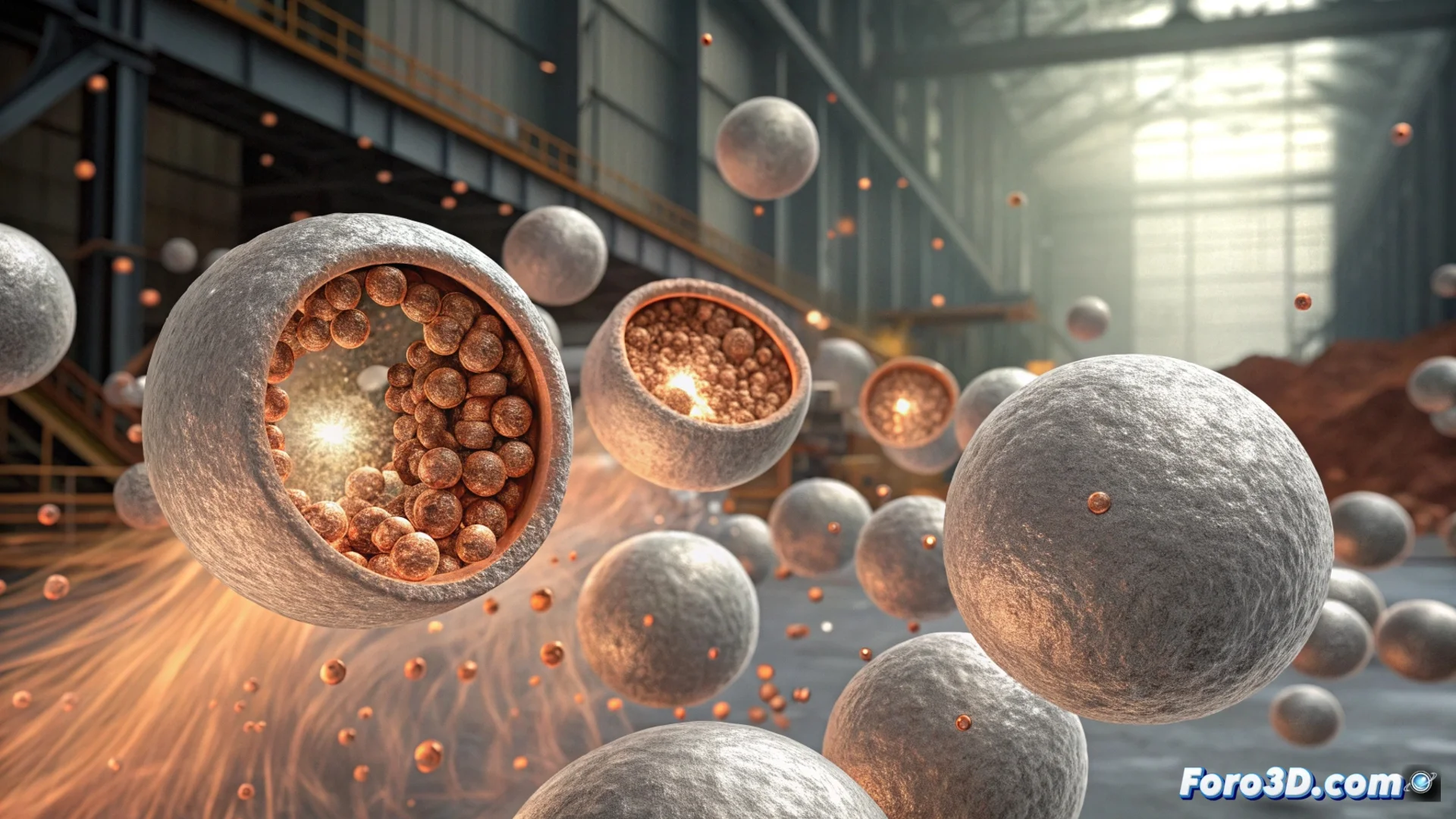

The company Continuum Powders expands its catalog with two innovative materials specifically designed for additive manufacturing. These are the metallic powders CuNi30 and CuNi10, formulated for processing with technologies such as DED (Directed Energy Deposition) and PBF (Powder Bed Fusion). These developments offer a viable alternative to traditional cobalt or pure nickel alloys, leveraging the inherent advantages of copper. 🔧

Technical Properties and Potential Applications

The two alloys differ in their composition and resulting properties. CuNi30, with 30% nickel, is characterized by its high corrosion resistance, especially in aggressive marine environments, and maintains good thermal conductivity. On the other hand, CuNi10, with 10% nickel, maximizes electrical and thermal conductivity. This combination of attributes enables the creation of complex and internal geometries that are unfeasible with subtractive manufacturing techniques.

Key Advantages of the New Alloys:- CuNi30: Ideal for components exposed to marine corrosion, such as parts in cooling systems or heat exchangers on ships.

- CuNi10: Optimized for applications where efficient heat and electricity transfer is critical, such as parts for renewable energy systems.

- Design Freedom: Both allow the manufacture of internal cooling channels or lightweight lattice structures that enhance the performance of the final component.

By using copper and nickel, more abundant materials, dependence on other more critical supply elements is reduced.

A Production Process with Lower Impact

Continuum Powders emphasizes that its method for producing these powders, based on gas atomization, requires less energy compared to conventional metallurgical processes. This approach, combined with the use of more accessible raw materials, aims to provide a more robust and less vulnerable supply chain.

Highlights of Sustainability:- Lower Energy Consumption: The atomization process to create the powder is more efficient than traditional production routes.

- Abundant Materials: Copper and nickel are prioritized over cobalt, a material often associated with geopolitical and supply challenges.

- Optimize the Value Chain: Industries can seek to manufacture more efficiently and reduce their resource footprint.

The Future Conductor of Additive Manufacturing

The launch of these alloys signals a clear trend in metallic additive manufacturing: not only creating impossible shapes, but also endowing components with superior functional properties. The ability to combine high conductivity with corrosion resistance in a single complex piece opens up a range of possibilities for sectors such as energy, aerospace automotive, and marine. The future of additive manufacturing not only shines, but conducts heat and electricity exceptionally well. ⚡