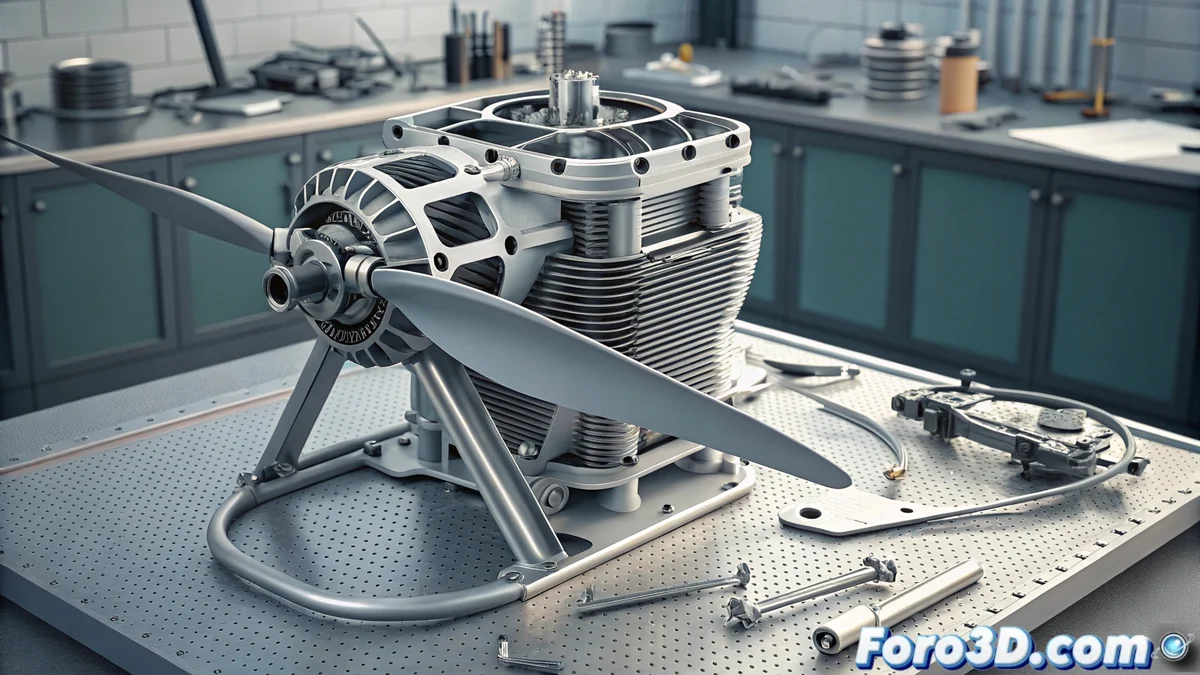

Beehive 3D Manufactures a Hydrogen Engine for Drones Using Metal 3D Printing

From Australia, the company Beehive 3D is developing an innovative alternative to conventional propulsion systems for unmanned aircraft. Its solution is a hydrogen engine manufactured entirely using metal 3D printing, which promises to overcome the limitations of current electric batteries. The goal is clear: extend the autonomy of drones and allow them to carry more weight. 🚁

Additive Manufacturing as a Key Advantage

The core of this technology lies in using 3D printing with aluminum alloy. This method allows for the creation of complex internal geometries that would be impossible or very costly to produce with traditional techniques. Instead of assembling multiple pieces, critical components such as the heat exchanger and the combustion chamber are manufactured as a single monolithic unit.

Benefits of integrating components:- Reduce the total number of parts, which simplifies the final assembly.

- Make the system lighter, by eliminating joints and superfluous materials.

- Increase overall robustness, as a single piece has fewer weak points than an assembled set.

The most productive hive is not that of the bees, but the one that prints engines so drones don't run out of energy.

Operation of the Hybrid Propulsion System

This engine does not operate by burning fuel in the traditional way. It is a hybrid system that combines high-pressure stored hydrogen with compressed air. The controlled reaction between these two elements generates the thrust necessary for flight. Additionally, a key aspect is that this process also produces electrical energy, which can power the drone's electronic and communication systems.

Main features of the engine:- Operates without combustion, which can make it more efficient and cleaner.

- Generates thrust and electricity simultaneously.

- Modular by design, to adapt it to different types and sizes of drones.

The Future of Drone Propulsion

Beehive 3D's project represents a strategic convergence between advanced additive manufacturing and alternative energies. By focusing on a compact and efficient design, they seek to solve two of the biggest challenges in unmanned aviation: limited autonomy and reduced payload. This technology could open new possibilities for long-duration missions in sectors such as logistics, precision agriculture, or surveillance. 🔋➡️💨