Airbus Manufactures OneWeb Satellite Components with Aluminum 3D Printing

To deploy the large OneWeb satellite constellation, Airbus has adopted additive manufacturing as the primary method. The company directly produces antenna panels and internal support structures using aluminum, achieving the manufacture of thousands of parts with a faster production cycle and lower final weight, a decisive factor in the space sector. 🛰️

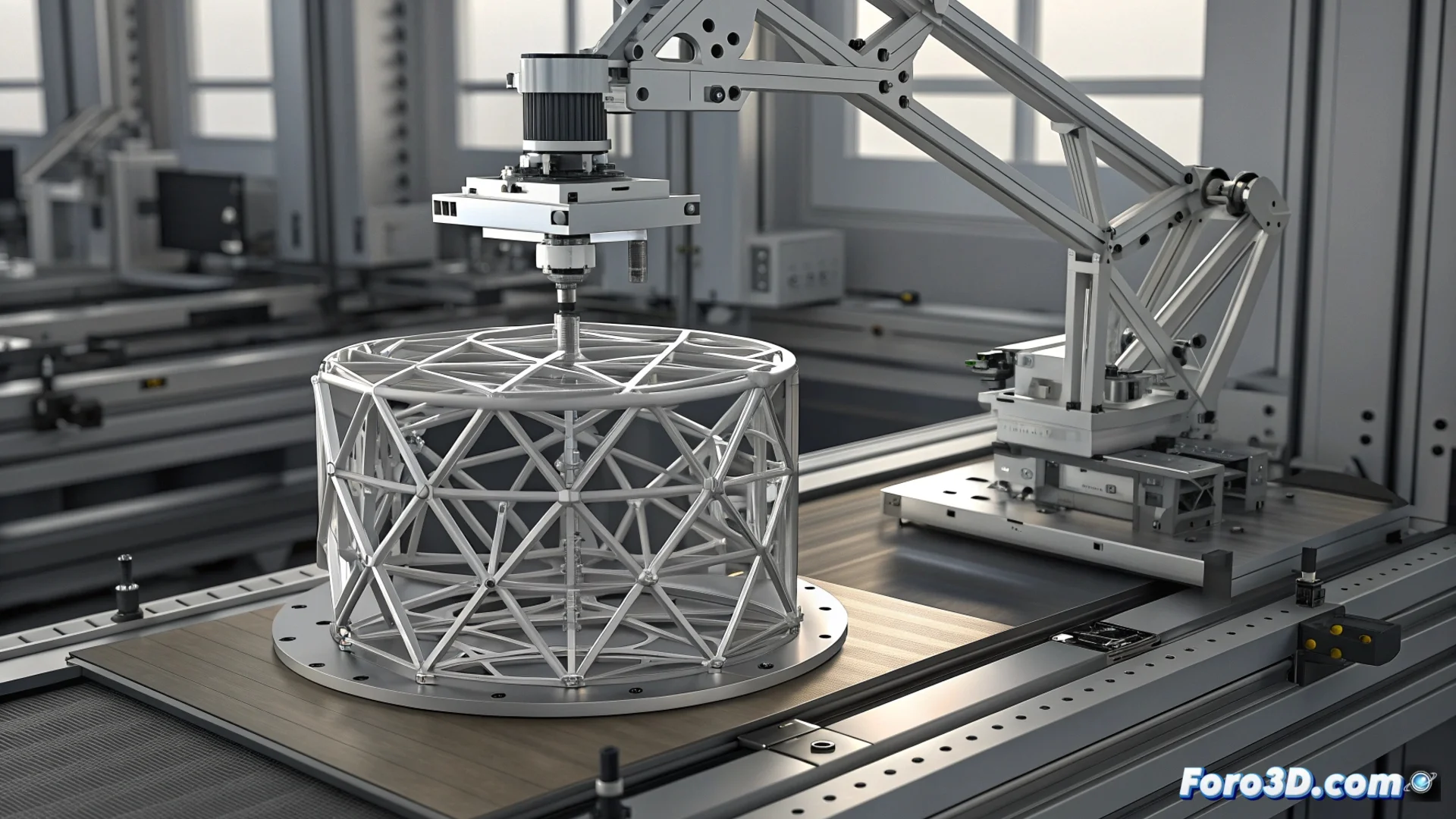

Additive Manufacturing Revolutionizes Satellite Production

Deploying hundreds of identical satellites requires manufacturing methods that are fast and easily scalable. Metal 3D printing addresses this challenge by combining multiple parts into a single complex component. This approach eliminates numerous assembly steps, reduces the necessary parts inventory, and shortens overall timelines. Additionally, the technology enables faster design iterations to meet specific technical requirements.

Key Advantages of Integrating Parts:- Reduce Assemblies: Multiple parts are joined into one, simplifying the assembly chain.

- Decrease Inventory: Fewer loose parts to manage and store.

- Speed Up Deliveries: Total time from design to final product is significantly shortened.

3D printing enables the manufacture of geometries impossible to achieve with traditional methods, optimizing the function and weight of each component.

Why Aluminum is the Chosen Material

Selecting aluminum for these parts seeks a precise balance between structural strength, reduced weight, and feasibility in the 3D printing process. The material must withstand the extreme conditions of launch and orbital operation. By manufacturing internal structures with optimized geometries, the necessary rigidity is achieved without adding superfluous mass, directly impacting the efficiency of the launch rocket and the satellite's operational life.

Aluminum Characteristics in This Context:- Strength-to-Weight Ratio: Offers good strength while maintaining low density.

- AM Compatibility: Processed reliably in metal 3D printers.

- Performance in Space Environment: Resists vibrations, loads, and extreme temperatures.

The Final Impact on Global Communications

This manufacturing approach not only optimizes production but is fundamental to the project's viability. Reducing the weight of each satellite allows launching more units per mission or using less powerful launchers, lowering costs. The ability to produce thousands of identical components quickly and precisely is what will make the complete constellation possible. The future of uninterrupted global streaming depends, in part, on these metal boxes being manufactured at a pace that far surpasses conventional assembly lines. 🚀