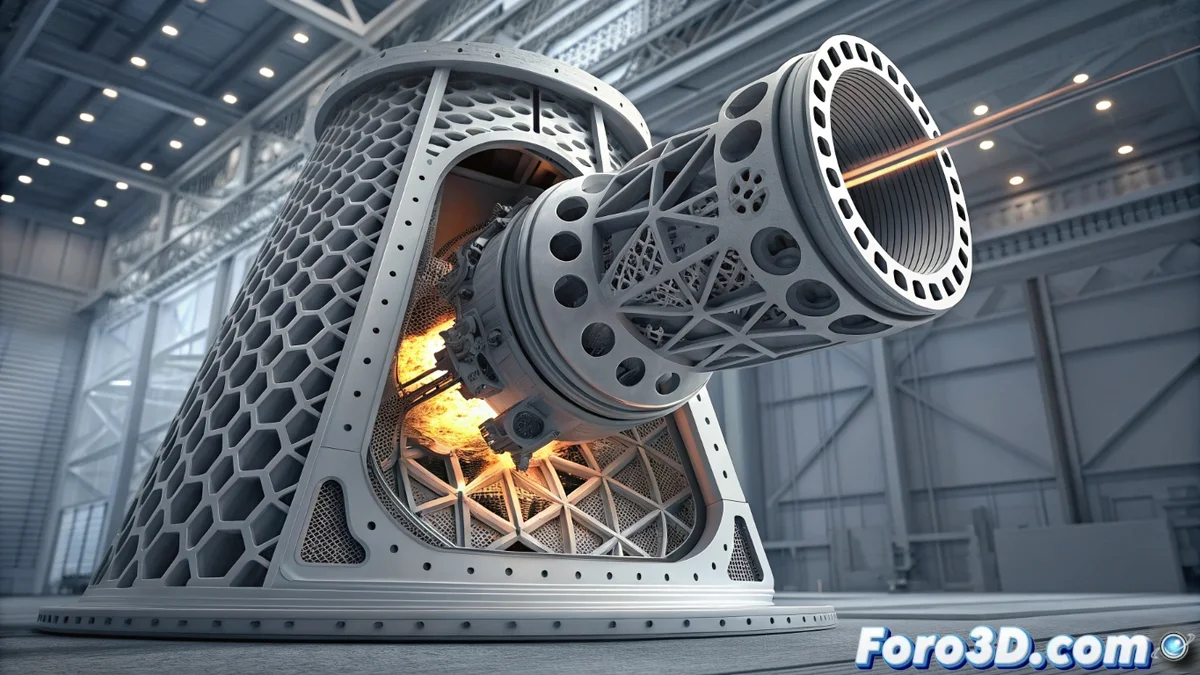

Aerojet Rocketdyne Manufactures Engine Housings for Drones Using 3D Printing

The company Aerojet Rocketdyne is applying additive manufacturing to create housings for its small-sized jet engines, intended to propel drones and missile systems. This technology enables the construction of internal geometries that would be unfeasible with conventional machining methods, consolidating functions that previously required many parts into a single component. 🚀

Redesigning the Engine Architecture with a Single Piece

The metal 3D printing process completely transforms how an engine is built. Instead of assembling dozens of components, a monolithic housing is manufactured in a single operation. This eliminates joints and seals between parts, increasing reliability and reducing potential failure points in the structure. Within this single piece, a network of channels through which fuel flows is integrated, serving to cool the engine before combustion.

Key Advantages of Monolithic Integration:- Reduce Parts: Transition from a complex assembly to a single manufactured unit.

- Improve Reliability: Eliminate potentially weak joints and seals.

- Optimize Cooling: Implement internal channels with complex shapes that enhance thermal management.

3D printing enables the creation of cooling channels with geometries impossible to machine, integrating the function directly into the housing wall.

Accelerate Development and Flexibilize Production

Using additive manufacturing provides great agility for developing and testing new designs. Engineers can modify digital files and have a functional prototype in a short time, accelerating innovation cycles. For serial production, this technique consolidates the supply chain, as it relies on fewer suppliers for specialized components.

Impact on the Product Cycle:- Iterate Designs Quickly: Test and modify functional prototypes in short timeframes.

- Simplify the Supply Chain: Reduce the number of suppliers and components to manage.

- Customize Engines: More easily adapt designs to the specific requirements of each mission or drone.

From the Office to the Sky: A Transformative Technology

Although the machine may resemble an office printer, it works with metallic powders and high-power lasers to fuse the material layer by layer. This method not only simplifies the mechanical architecture but redefines how advanced propulsion systems are designed and produced. The result is a more reliable, efficient, and faster-to-develop engine, demonstrating the potential of 3D printing in high-demand sectors such as aerospace and defense. ✈️