A Danish institute develops a 3D-printed heat sink for data centers

A consortium between the Danish Technological Institute and the company Heatflow is evaluating a new cooling component created with additive manufacturing, intended for server processors and graphics units. This initiative is part of the European research project AM2PC. The system is based on a two-phase passive cooling method, which enables dissipating thermal energy without using mechanical elements like fans. The main objective is to drastically reduce the electricity used by air conditioning equipment in data facilities. 🔥

Operation based on the thermosyphon principle

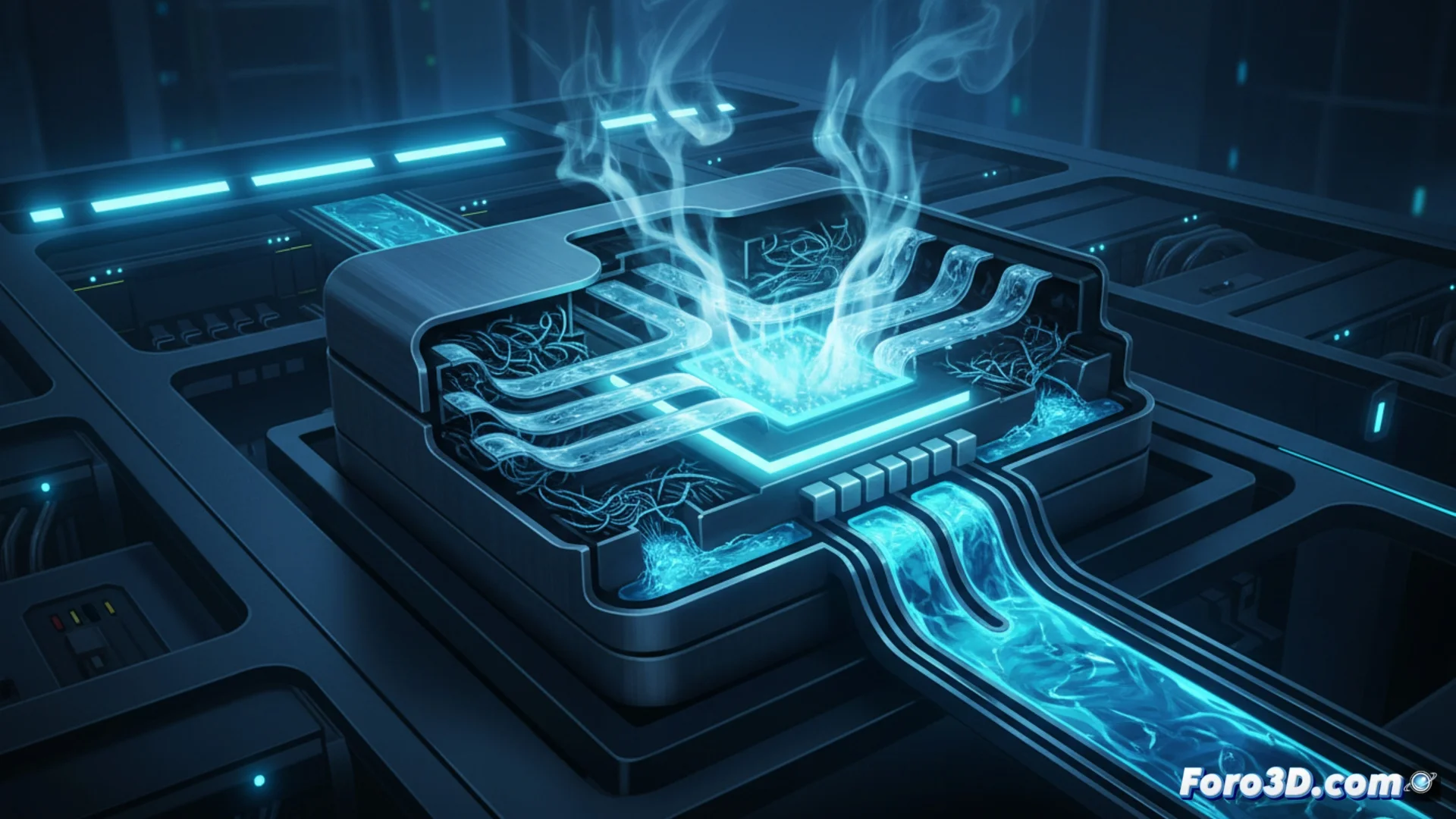

The device operates as a heat pipe. Inside, a refrigerant fluid vaporizes upon capturing heat from the electronic chip. This vapor rises to a section where it condenses, releases the thermal energy, and turns back into liquid. By the action of gravity, the liquid returns to the evaporation zone, establishing an automatic and perpetual cycle. Lacking moving parts, the design offers greater reliability and less noise compared to traditional air coolers.

Key advantages of the passive system:- Eliminates the need for fans or pumps, reducing direct electrical consumption.

- The autonomous cycle by gravity increases system reliability and lifespan.

- Operates significantly more quietly than air cooling solutions.

Additive manufacturing allows creating internal geometries that are unfeasible with conventional production techniques, optimizing heat flow.

Metal 3D printing enables innovative designs

Metal additive manufacturing was key to producing the heat sink's internal structure, which incorporates capillary channels and vapor chambers with optimized design. These complex shapes would be extremely difficult or impossible to achieve with standard manufacturing methods. This design freedom allows the component to fit precisely to the thermal profile of specific processors, improving efficiency in heat transfer. ⚙️

Contributions of the complex geometry:- Capillary channels that facilitate the return of the liquid refrigerant by capillarity.

- Vapor chambers designed to maximize the thermal transfer area.

- Precise adaptation to the thermal footprint of specific CPUs and GPUs.

Future prospects for efficient cooling

This advance suggests a change in how heat is managed in power electronics. Instead of relying on active systems that consume energy, the integration of passive cooling manufactured with 3D printing could mark a turning point. It represents significant progress in applied thermodynamics and a promising advancement for reducing operational costs in large-scale data centers. The combination of intelligent design and additive manufacturing opens a new path for cooling components in a more sustainable and effective way. 💡