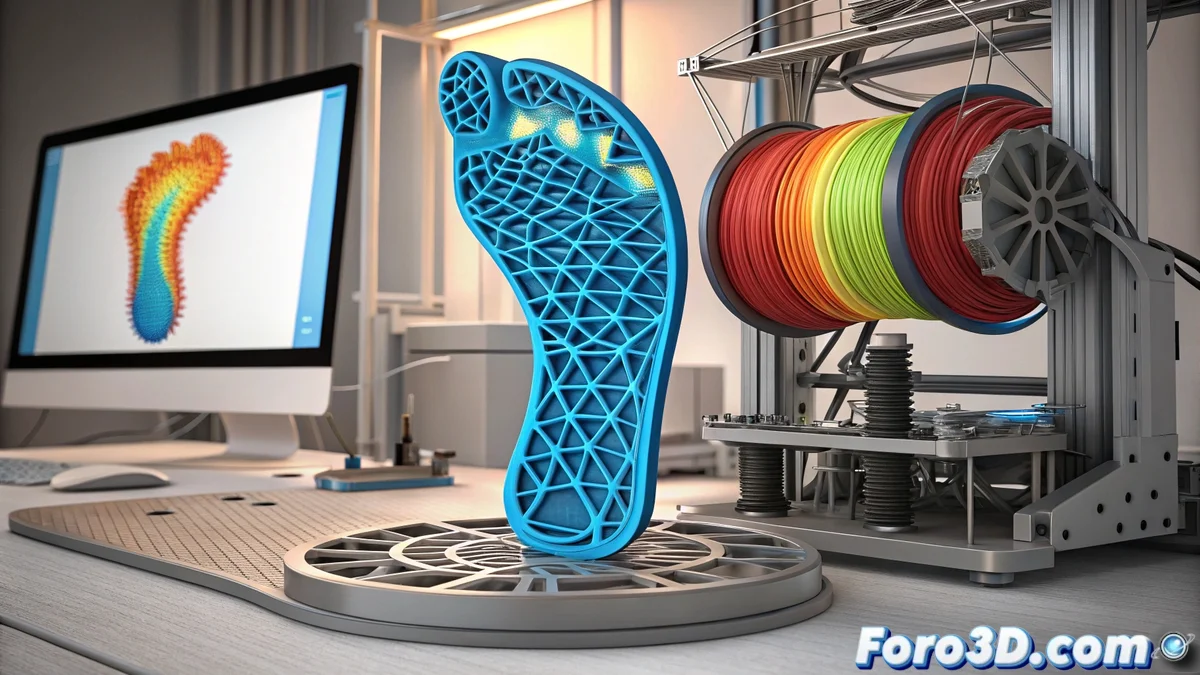

3D Printing to Customize Footwear with Anatomical Supports

Additive manufacturing opens a direct path to create footwear elements that fit the unique shape of each foot. This process begins by digitizing the user's anatomy using a scanner, generating a precise 3D model that serves as the basis for designing custom supports. 🦶

From Scanning to Customized Insole

Capturing the plantar footprint with a specialized scanner is the first step. This digital model allows designing an inner insole that provides exact support for the foot arch. The technology translates individual biomechanical needs into a physical object, starting from scratch for each person.

Key process for creating supports:- Digitalize the foot shape with a 3D scanner to obtain precise data.

- Use the 3D model to design a support geometry that adapts to the arch and pressure.

- Translate the user's unique biomechanical characteristics into a print-ready file.

The precision of the scan defines the final result: it faithfully captures the relief and unique character of your footprint.

Flexible Materials for Dynamic Components

For users seeking more than an insole, it is possible to manufacture complete midsoles. Flexible filaments such as TPU are used, which provide cushioning and a structure that behaves dynamically. This material allows the printed piece to adapt to walking or running, distributing loads and absorbing impacts in a personalized way.

Characteristics of printed midsoles:- Made with flexible filaments like TPU to achieve cushioning and movement.

- The piece behaves dynamically, adapting to the action of walking or running.

- The result is a component that distributes loads and absorbs impacts uniquely for the user.

Advantages of a Personalized Approach

This method solves comfort or performance problems starting from the unique shape of each foot. Unlike generic solutions, the support is generated specifically for an individual. Athletes can benefit from configured cushioning for their footprint pattern. 3D printing makes it feasible to produce complex internal geometries, difficult to achieve with traditional methods. 🏃♂️