3D Printing in Fusion Energy: Parts That Withstand 5 Million Atmospheres

The company First Light Fusion is revolutionizing fusion energy with an unexpected ally: 3D printing. Their new pressure amplifiers, made of tantalum, are capable of withstanding extreme conditions, as if you were trying to compress the ocean into a bottle. 🌊💥

It's not easy to contain the sun in a box, but at least now the box is 3D printed.

Designed to Withstand the Unimaginable

These parts are not just any decorative components: they must withstand 5 million atmospheres, a pressure that would shatter most materials. The amazing thing is that the 3D printed versions match the performance of those made with traditional methods, but with greater design flexibility. 🚀

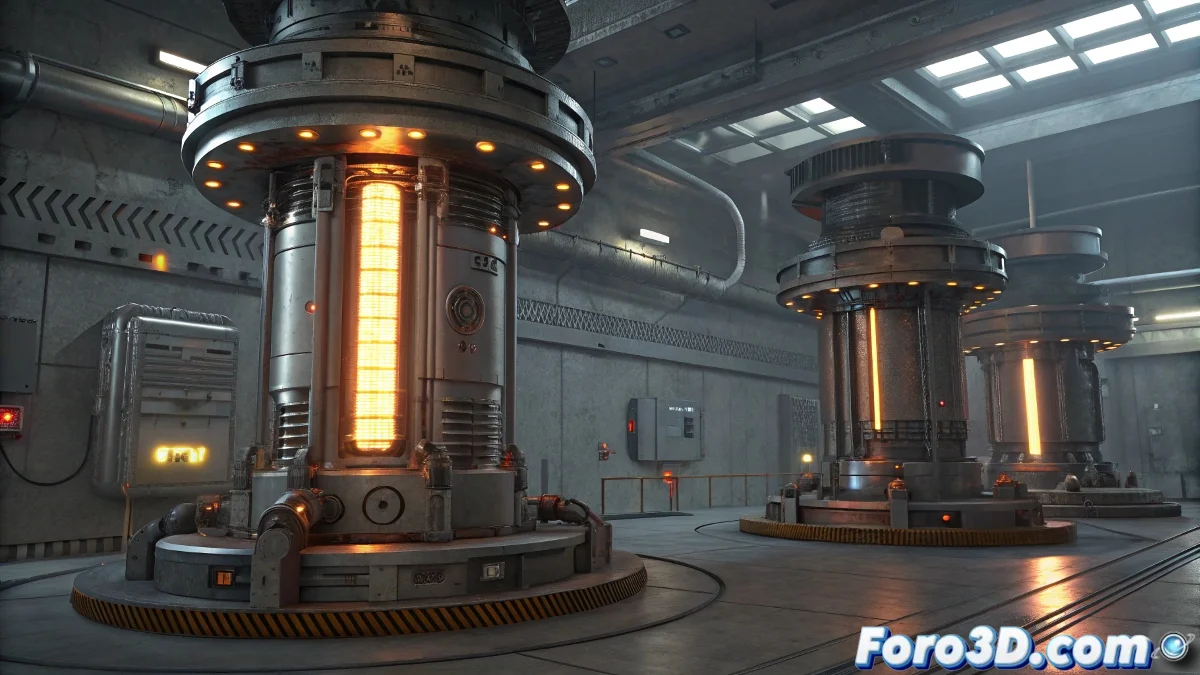

If you're a 3D artist, imagine recreating this challenge in software:

- Deformation simulations under extreme pressure

- Stressed metal textures with Displace

- Hyperrealistic rendering in Cycles or V-Ray

When 3D Printing Meets the Energy of the Future

This breakthrough is not just a technical achievement, but a sign that additive manufacturing is reaching sectors where the margin for error is zero. While some of us are still struggling with the topology of a model, others are already printing parts that could change the energy future. 😅

Among the advantages of this approach are:

- Greater speed in producing complex parts

- Possibility of customization for each experiment

- Reduction of costs in critical materials

So the next time your 3D printer fails with a simple keychain, remember: there are machines printing parts that contain mini-stars. And you thought PETG was complicated... ☀️🤖