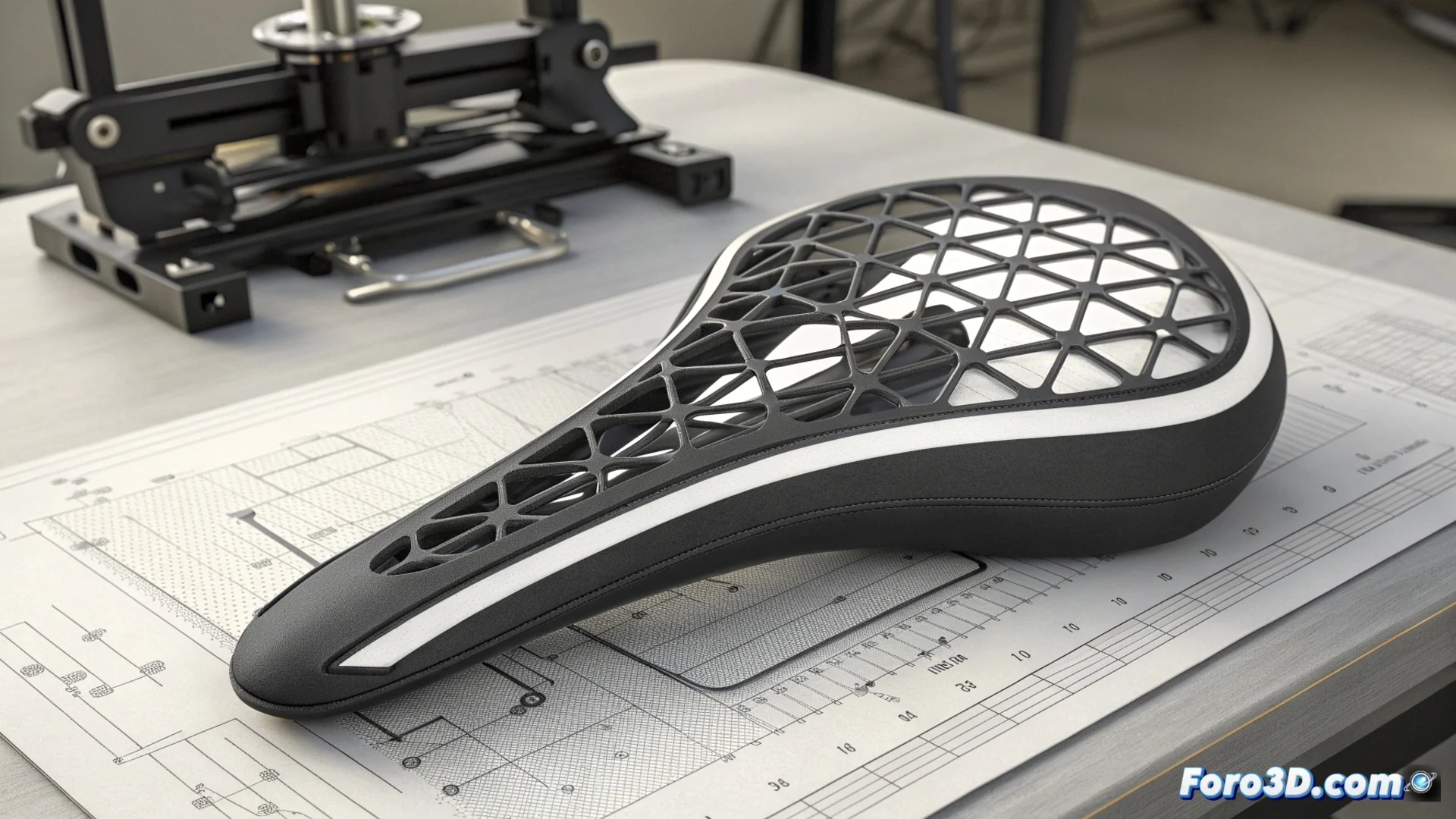

3D Printing Customizes the Stealth 3D Cycling Saddle

Additive manufacturing is consolidating its presence in the world of cycling, where brands are exploring how to create custom components with better performance. The Dutch company PRO presents its first saddle using parts made with 3D printing, the Stealth 3D. This method enables the creation of internal configurations that traditional processes could not achieve, directly influencing how the user perceives comfort and how forces are distributed over the seat. 🚴

An Internal Structure That Adapts

The Stealth 3D integrates a central zone produced in 3D with a lattice pattern. This internal mesh can be modified in terms of its density and shape in specific areas, in order to dampen terrain vibrations and adapt to each person's anatomy. The goal is to reduce high-pressure points and distribute weight more evenly, which can help reduce discomfort on long rides.

Key advantages of the additive process:- Allows iterating and testing complex designs faster than using conventional molds.

- Accelerates prototyping and enables the creation of custom internal geometries.

- Can reduce the amount of material used, as it is only deposited where strictly necessary.

The promise is that your butt, finally, can enjoy a customized experience without having to go to the saddle craftsman's workshop.

Impact on Design and Manufacturing

By 3D printing the component's core, engineers gain unprecedented design freedom. The final product combines this additively manufactured part with other common elements, such as the outer cover and mounting rails. This approach not only seeks to revolutionize comfort but also to demonstrate how technology can optimize the performance of sports equipment.

Features of the final result:- Core with lattice geometry 3D printed for pressure management.

- Process that accelerates development and refinement of the product.

- Approach that customizes the cyclist's experience through internal design.

The Future of Two-Wheeled Equipment

This launch underscores a clear trend: 3D printing is no longer just for prototypes, but for producing high-value end components. By allowing precise adjustment of internal parameters, it opens the door to a new generation of sports equipment where comfort and efficiency are designed digitally from the inside out. The race to optimize every gram and every point of contact with the athlete has a powerful new ally. 🔧