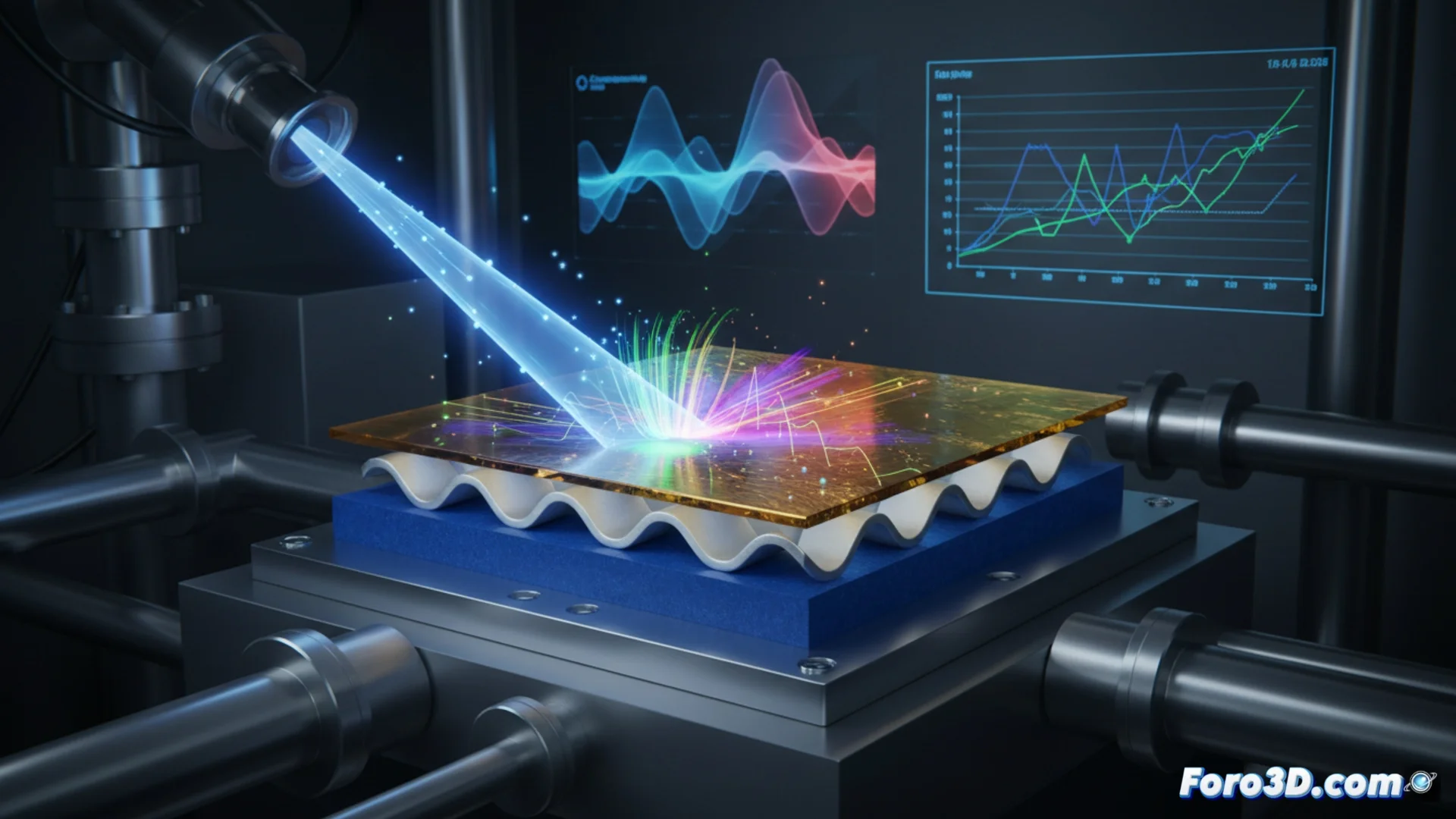

XPS Spectroscopy Accelerates the Development of Protective Layers for Superconductors

The X-ray photoelectron spectroscopy (XPS) technique positions itself as a key tool for analyzing coatings on niobium quickly and without damaging the material. This approach allows understanding how these barriers prevent oxygen from penetrating and forming oxides, a factor that degrades the performance of advanced quantum components. 🔬

Selecting the Most Robust Materials

The study subjects seventeen different compounds to common treatments in production, such as applying heat, removing photoresists, and cleaning with acidic agents. The goal is to identify which layers maintain their integrity and prevent the underlying metal from oxidizing, which is essential for manufacturing devices with stable and predictable electrical behavior.

Key Advantages of the Evaluation Process:- Allows testing many materials efficiently before integrating them into a complete device.

- Provides precise data on oxidation resistance after each manufacturing step.

- Layers that pass this test are later validated in real microwave resonators to measure their losses.

Sometimes, solving a complex quantum challenge starts by preventing the metal from darkening like an old teapot.

Accelerating the Path to Quantum Computing

Using XPS analysis in this way radically optimizes the design cycle for quantum computing. Instead of building and measuring each prototype exhaustively, the performance of the protective barrier can be predicted in advance. This allows exploring a wider range of options in less time.

Methodological Impact:- Saves time and resources by filtering promising materials in an early phase.

- Facilitates exploring new combinations of compounds for surface engineering.

- Constitutes a significant advance for improving the coherence of superconducting qubits.

From Characterization to Functional Device

The transition from surface analysis to practical validation is crucial. Protective layers that prove effective with XPS are later incorporated into superconducting resonators, where critical parameters such as dielectric losses are measured. This final step confirms that the material not only resists oxidation but also allows the system to operate with high efficiency, closing the cycle between materials development and real-world application. 🚀