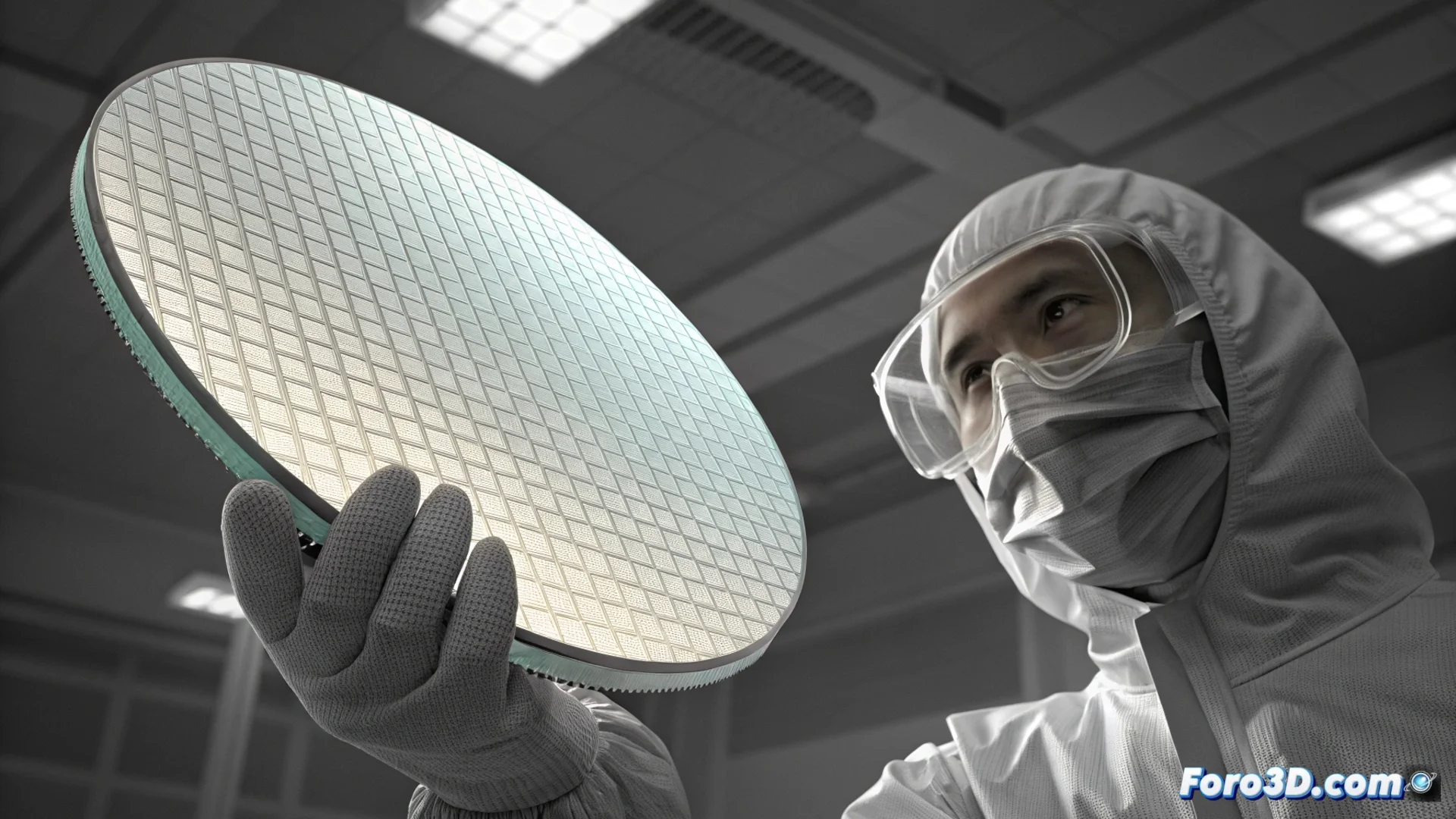

Wolfspeed Manufactures the First 300 mm Silicon Carbide Wafer

The power semiconductor industry has just overcome a key technical barrier. A team of engineers in the United States, led by the company Wolfspeed, has succeeded in creating the first monocrystalline silicon carbide (SiC) wafer with a diameter of 300 millimeters. This leap from the previous 200 mm standard is a crucial milestone for manufacturing more components per processing cycle. 🚀

Why Increasing Wafer Size Matters

Manufacturing on larger-diameter wafers radically optimizes the process. By expanding the usable area, many more power devices can be produced on a single wafer. This directly helps scale up the supply of SiC-based components, which are vital for growing sectors like electric vehicles and renewable energy infrastructure. These chips operate at higher frequencies and temperatures than traditional silicon, enabling more compact and efficient system designs.

Key Advantages of Silicon Carbide:- Wide Bandgap: Supports higher voltages and loses less energy as heat.

- Higher Efficiency: Allows power electronic devices to perform better.

- Extreme Temperatures: Operates in conditions where normal silicon would fail.

The transition to 300 mm wafers represents a monumental engineering challenge, as maintaining crystalline quality and uniformity at a larger diameter is extremely complex.

The Technological Challenge and Industrial Context

Achieving this breakthrough was not easy. The main challenge was maintaining monocrystalline quality and uniformity on a 300 mm substrate, a highly complex engineering process. This achievement positions Wolfspeed at the forefront, although other companies are also researching to achieve similar goals. The development responds to growing demand for more efficient power electronics.

Comparison with Silicon's Evolution:- This advance recalls the historic transition in the silicon industry, which moved from 200 mm to 300 mm wafers.

- That transition promised and achieved significant cost reductions.

- The question now is whether the SiC industry can adopt this new format with the same speed and success.