Why Electric Vehicle Battery Packs Are Not Modular

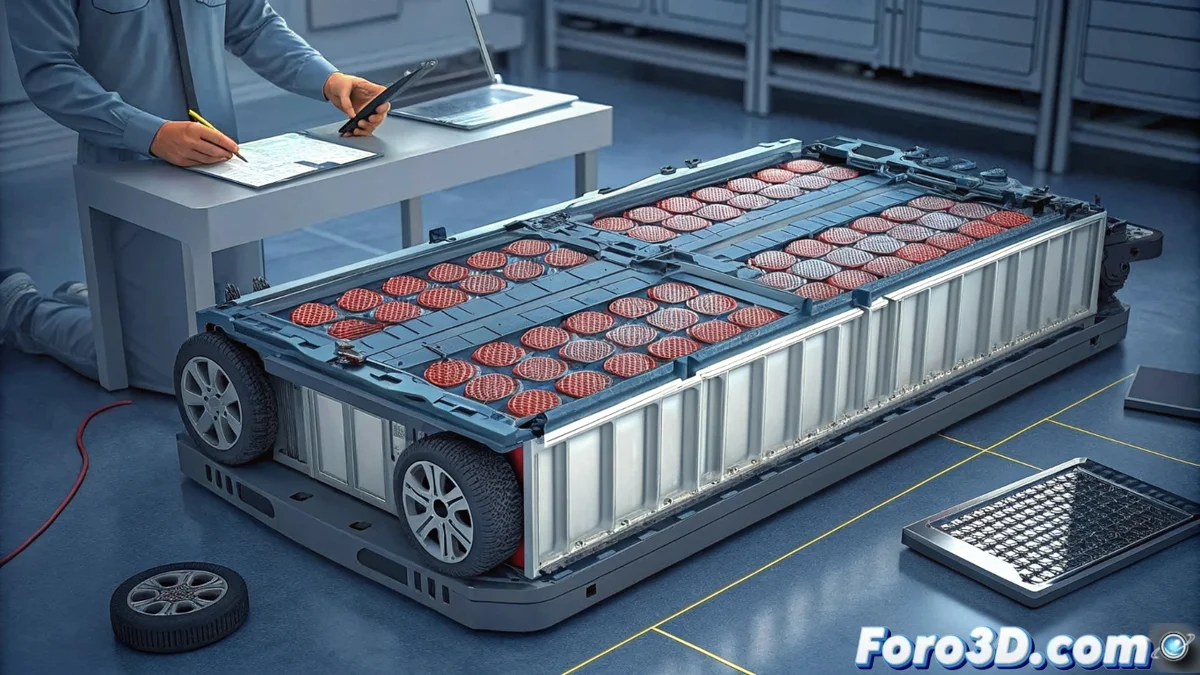

The heart of a modern electric vehicle is a complex assembly that can contain thousands of individual cells. These are organized in series and parallel configurations to achieve the necessary voltage and capacity. A critical component, the BMS (Battery Management System), monitors and protects this network. 🔋

The BMS Acts as an Inflexible Guardian

The main function of the BMS is to monitor each cell, balance its charge, and protect the entire pack. When certain cells degrade or fail, their internal resistance varies, creating a dangerous imbalance. To avoid risks such as overheating, the software system responds drastically.

The system's response to failures:- Detects cells with performance outside the parameters.

- Limits the vehicle's functionality or completely disables the affected battery module.

- Interprets a group of cells as an indivisible operational unit.

The software locks the entire pack if cells fail. There is no physical or software path to isolate and replace only the defective ones.

The Consequences of a Non-Modular Design

This architecture turns a localized failure into a major problem. Without being able to repair only the damaged part, the official solution involves replacing the entire battery pack. This operation has a very high cost, often exceeding ten thousand euros. 💸

Impact of this lack of modularity:- Exorbitant repair cost for the owner.

- A huge component is discarded where only a small percentage of its elements fail.

- Approach that contradicts basic principles of repairability and sustainability.

A Premature and Costly End

The result is that an electric vehicle can become unusable because a few of its thousands of cells fail. The system dictates that the entire battery must be removed, forcing a complete replacement with significant economic and environmental impact. This reality poses a crucial challenge for the industry on how to design more repairable and durable systems. ⚡