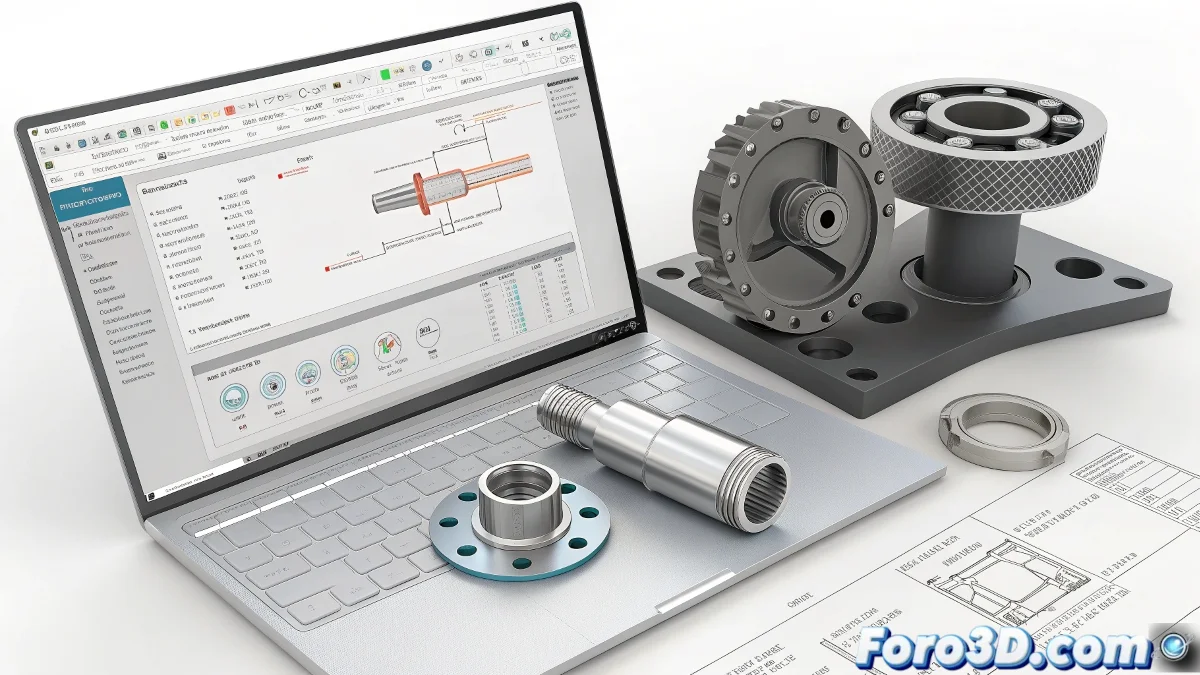

PTC Creo: the parametric ecosystem for serious engineering

In the universe of professional mechanical design, PTC Creo represents much more than just CAD software: it is a complete product development ecosystem built around a robust and proven parametric core. What began as Pro/ENGINEER—revolutionizing the industry with parametric modeling in the 90s—has evolved into a platform that governs the entire product lifecycle, from the initial concept to post-sale service. For companies designing complex products and requiring absolute control over their development, Creo is not just another option; it is the strategic choice. 🏭

Parametric core: the DNA of absolute control

The heart of Creo beats in its feature-based parametric engine, where every modeling operation is recorded in a fully editable historical tree. This approach is not just a working methodology; it is a design philosophy based on intent that captures not only the geometry, but the reason behind each design decision. Parameters and relationships allow creating intelligent models that adapt automatically to changes in requirements, maintaining design integrity even in complex modifications. For products with multiple variants or that constantly evolve, this capability is invaluable. 🔧

Features of the parametric core:- fully parametric feature tree

- management of design relationships and dependencies

- interconnected global and local parameters

- capture of design intent in every operation

Design of complex systems: beyond loose parts

Where Creo truly demonstrates its power is in complex systems and massive assemblies design. Top-down design tools allow defining product architectures at the schematic level, then propagating these definitions to all system components. Cross-reference management, interfaces, and shared workspaces facilitate distributed teams collaborating on the same product without conflicts. For aeronautics, automotive, or industrial machinery—where a product can have thousands of components—this capability is not a luxury, it is an absolute necessity. ✈️

Creo does not model geometry, it models design intent that becomes geometry

Integrated simulation: validation from the first sketch

Creo integrates simulation capabilities that previously required specialized software. Finite element analysis (FEA), mechanism dynamics, and fluid dynamics (CFD) are available directly in the design environment, allowing validating products while designing them. This integration eliminates export/import cycles and ensures analyses always use the current geometry. Engineers can explore "what if" scenarios in real time, optimizing designs before committing resources to physical prototypes. 📊 Integrated simulation modules:

- static and dynamic structural analysis

- thermal and heat transfer simulation

- mechanism and kinematics analysis

- fatigue and durability studies

Manufacturing and production: from model to reality

The Creo ecosystem extends its parametric capabilities beyond design into computer-aided manufacturing. Mold, sheet metal, and machining tools maintain associativity with the master model, so design changes propagate automatically to manufacturing. Technical documentation generation—drawings, specifications, bills of materials—is fully parametric, eliminating inconsistency errors between design and production. This bidirectional connection significantly accelerates time-to-market. 🏗️

Integration with the PTC ecosystem: IoT and augmented reality

As part of the PTC ecosystem, Creo benefits from unique integrations with ThingWorx for IoT and Vuforia for augmented reality. Field product sensor data can be fed directly into parametric models, enabling designs based on real usage data. Augmented reality assembly and maintenance instructions are generated automatically from parametric 3D models. This connection between the digital and physical worlds represents the natural evolution of parametric into the Industry 4.0 era. 🌐

Main industrial applications:- industrial machinery and heavy equipment design

- development of complex consumer products

- aerospace and defense engineering

- medical equipment and precision devices

PTC Creo represents the mature evolution of parametric modeling into a complete product development ecosystem. It is not simply a tool for creating 3D geometry, but a system for capturing, managing, and executing design intent throughout the entire product lifecycle. For companies that need absolute control over complex products, value design knowledge reuse, and operate in industries where precision and traceability are critical, Creo has no equal. It is the choice for those who take engineering as seriously as the products they create. 💡