Industrial Additive Manufacturing Takes a Quantum Leap

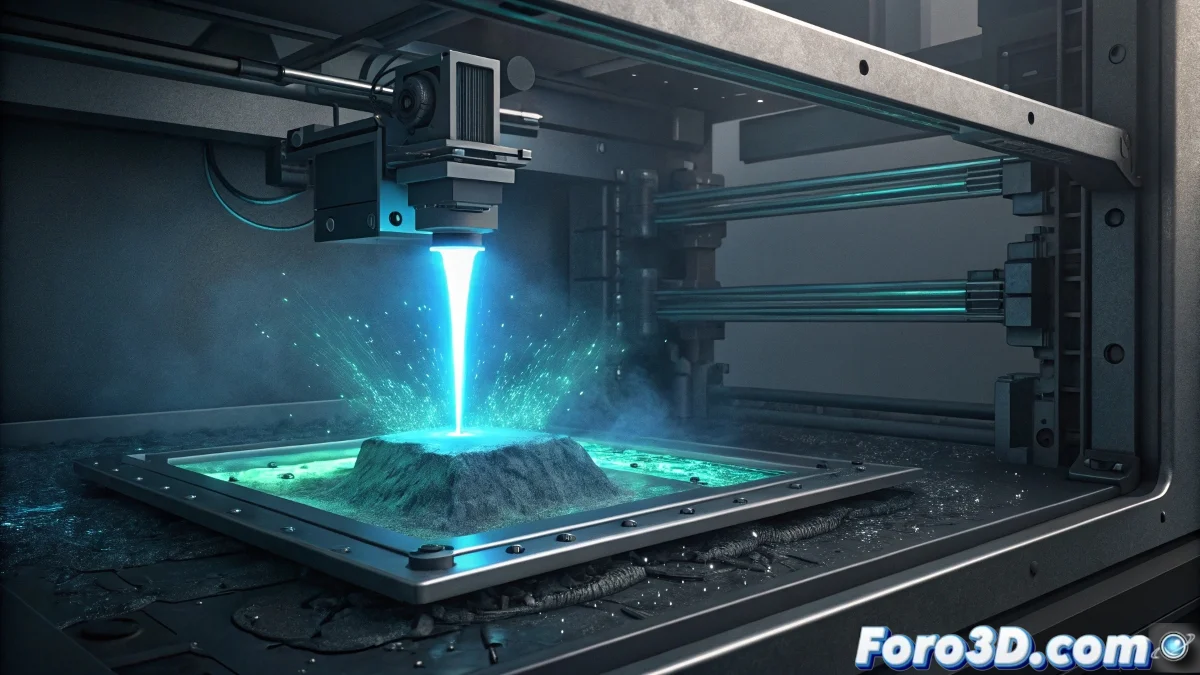

Vulcan, a company specialized in advanced additive manufacturing solutions, has officially launched its MX series of metal 3D printers, representing a significant advancement in the evolution of digital manufacturing. This new line is specifically designed for large-scale industrial production environments, incorporating Directed Energy Deposition (DED) technology with multi-material capabilities and advanced automation that challenge the traditional limits of metal 3D printing.

What sets the MX series apart is its focus on real industrial productivity, not just prototyping capability. These machines are built to operate continuously in demanding manufacturing environments, with automated material handling systems, real-time process monitoring, and the ability to produce large-format parts at speeds up to 5 times faster than conventional metal printing systems.

When 3D printing leaves the lab and enters the production line, the industrial revolution truly begins

Revolutionary Multi-Head Architecture

The technological heart of the MX series is its independent multi-print-head system that can operate simultaneously on the same part or on different projects independently. Each print head uses advanced DED technology with precise atmosphere control and real-time thermal monitoring systems that ensure consistent quality throughout the manufacturing process.

The multi-head configuration is not merely redundant—it is designed to work cooperatively on complex parts, allowing different heads to specialize in different geometric features or materials. One head can be dedicated to building support structures with economical material, while another works simultaneously on the critical features of the final part with high-performance alloys.

- Independent DED heads operating simultaneously

- Advanced atmosphere control for different materials

- Real-time thermal monitoring

- Cooperative work between specialized heads

DED Technology Optimized for Production

The MX series uses an advanced variant of DED technology (Directed Energy Deposition) that combines high-power lasers with optimized metal powder feeding. Unlike traditional DED systems, Vulcan's implementation incorporates dynamic powder flow control that automatically adjusts parameters based on the geometry being built, resulting in higher material efficiency and better surface quality.

The system is compatible with a wide range of metal alloys, from stainless steels and tool steels to nickel-based superalloys and aerospace titanium. The ability to change materials on the fly enables the creation of multi-material parts with gradual transitions—a feature particularly valuable for components requiring different properties in different sections.

In additive manufacturing, the real magic happens when the material meets the energy at the perfect point

- DED with high-power lasers and powder feeding

- Dynamic flow control for material efficiency

- Wide range of compatible alloys

- Multi-material transitions in the same part

Automation and Industrial Workflow

The MX series is designed from the ground up for seamless integration into existing production lines. It incorporates automated material handling systems that can feed different metal powders according to the requirements of the current job. Automatic material changes reduce downtime between jobs, while gas filtration and recirculation systems maintain optimal process conditions continuously.

The job preparation software includes intelligent nesting algorithms that maximize the use of build volume, and process simulation tools that predict and compensate for thermal distortions before they occur. Integration with MES (Manufacturing Execution System) enables complete tracking of the manufacturing process from design to finished part.

Scalable Build Volumes

The MX series is available in four volume configurations designed for different production needs. The MX-400 model offers a 400x400x400 mm volume ideal for medium-sized parts and small batch production. The MX-800 doubles these dimensions for larger components or more efficient production. The MX-1200 and MX-1600 models provide large-format capabilities for industries like aerospace, energy, and automotive that require substantial-sized parts.

Each model maintains the same process precision and quality regardless of volume, thanks to automatic calibration systems and thermal compensation that ensure consistency across all areas of the build volume. Larger systems incorporate multiple processing stations that can operate independently or coordinate for particularly large parts.

- MX-400 for medium parts and small batches

- MX-800 for larger components

- MX-1200 for large-format applications

- MX-1600 for the largest parts

Specific Industrial Applications

The MX series is finding immediate application in industries where geometric complexity combines with high-performance requirements. In the aerospace sector, it enables the manufacture of turbine components with internal cooling channels that would be impossible to produce with traditional methods. In the medical industry, it facilitates the creation of custom implants with optimized porous structures for osseointegration.

The molds and tooling sector particularly benefits from the ability to incorporate conformal cooling channels that dramatically improve molding process efficiency. Spare parts manufacturing for industrial machinery and heavy vehicles can be done on demand without the need for costly inventories.

The true advantage of additive manufacturing is not doing the same thing faster, but doing what was previously impossible

Economic Considerations and Return on Investment

Vulcan has designed the MX series with a clear focus on ROI for manufacturers. Although the initial investment is substantial, the near 95% material efficiency combined with reduced manufacturing times results in typical payback periods of 12-18 months for continuous production applications. The ability to consolidate multiple components into a single part eliminates assembly costs and improves reliability.

The service model includes predictive maintenance based on continuous machine condition monitoring, and regular software updates that extend equipment life and continuously improve capabilities. Guaranteed performance contracts assure manufacturers that the machines will meet specified productivity levels.

The Future of Industrial Additive Manufacturing

With the launch of the MX series, Vulcan is not just introducing new machines—it is defining a new standard for what additive manufacturing can achieve in industrial production environments. These printers represent the mature convergence of multiple technologies—robotics, materials science, artificial intelligence, and digital manufacturing—in integrated platforms that finally fulfill the promise of additive manufacturing as a viable alternative to traditional manufacturing processes.

For the global manufacturing industry, the MX series means that metal 3D printing has officially come of age, transitioning from prototyping technology to a legitimate production solution capable of competing with—and often surpassing—established manufacturing methods.

It seems that in the world of additive manufacturing, the only thing that doesn't need to be 3D printed is the enthusiasm for what's next 🔥