Virtual Simulation in Tinkercad: Design Verification Before Manufacturing

Tinkercad's Sim Lab provides a digital space where creators can analyze the behavior of their projects under realistic conditions before materializing them. This platform integrates elements such as gravity, motion systems, and mechanical connections to observe interactions between components under various scenarios. Designers adjust configurations and anticipate potential failures without building physical prototypes, saving time and resources during development. 🚀

Components Available in the Simulation Environment

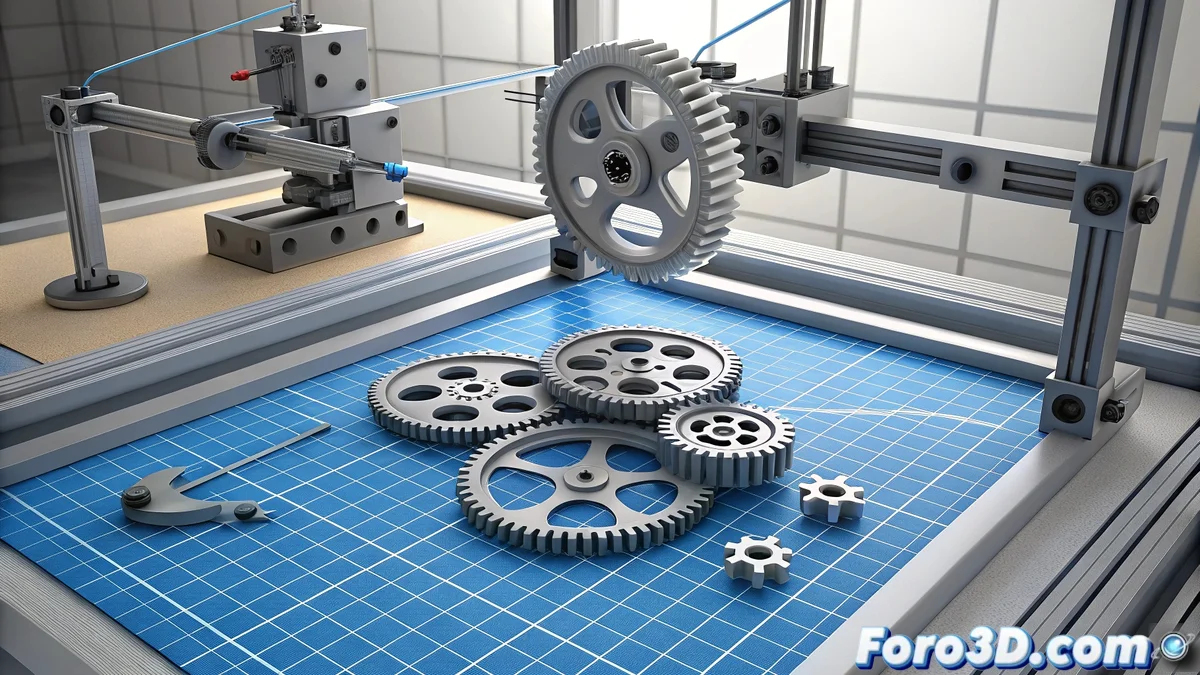

Within the Sim Lab, users access tools like rotating shafts, electric motors, gears, and various types of joints that mimic real mechanical behaviors. Gravity can be enabled or disabled depending on the project, allowing simulation from terrestrial mechanisms to devices for microgravity environments. Each element is parametrizable individually, offering control over speed, force, direction, and other key physical variables. 🔧

Highlighted Elements of the Sim Lab:- Rotation shafts and electric motors for realistic movement

- Gear systems that replicate power transmissions

- Adjustable mechanical joints for precise connections

Simulation sometimes reveals that our brightest designs behave like a flan in a centrifuge, humbly reminding us that the laws of physics are indifferent to our overflowing creativity.

Practical Applications for Creators and Students

This functionality is especially valuable for makers and students working on robotics, engineering, or mechanics projects. It allows validating complex concepts such as power transmissions, lever systems, or articulated mechanisms before investing in materials and manufacturing time. Users identify weak points, interferences between parts, or balance issues that might go unnoticed in static models, facilitating rapid iterations and continuous improvements. 💡

Key Advantages of Virtual Simulation:- Early detection of structural and motion failures

- Resource optimization by avoiding unnecessary physical prototypes

- Ability to test designs in extreme conditions or microgravity

Impact on the Creative Design Process

The ability to simulate behaviors before manufacturing transforms the workflow, allowing safe and efficient experimentation. Designers can explore multiple variants, adjust physical parameters, and refine their creations without costly risks. This tool not only accelerates development but also fosters innovation by enabling bold tests that would otherwise be prohibitive. ✨