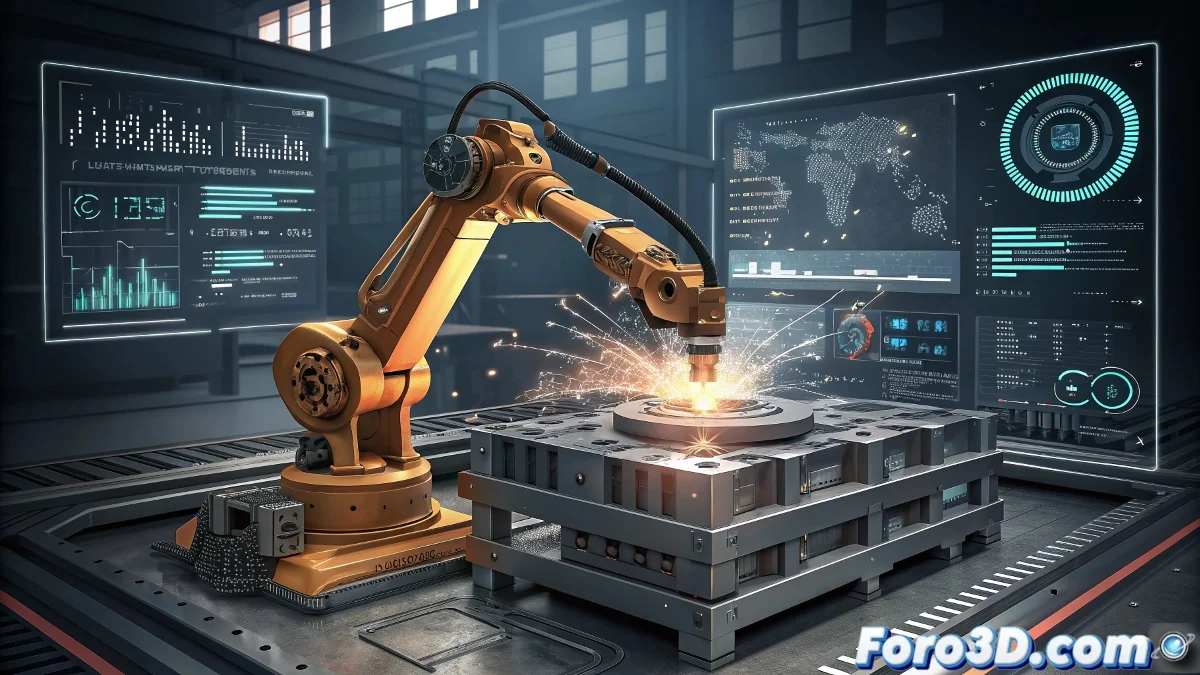

Virginia Tech Combines AI with Wire-Arc Additive Manufacturing to Revolutionize Metal Production

Researchers at Virginia Tech are pioneering a transformative integration between artificial intelligence and wire-arc additive manufacturing (Wire-Arc AM) that is redefining the boundaries of metal parts production. This advanced metal 3D printing technique, powered by sophisticated AI algorithms, enables real-time optimization of manufacturing parameters with unprecedented precision and adaptability. The approach is demonstrating extraordinary capabilities for reducing critical defects and improving structural properties in high-demand components, marking a significant milestone in the evolution of advanced manufacturing. 🔧

Wire-Arc AM: Fundamentals of Metal Additive Manufacturing

Wire-arc additive manufacturing represents a disruptive technology in the production of large-format metal components. Unlike powder-based methods, Wire-Arc AM uses metal wire as feedstock and an electric arc as energy source to deposit molten metal in a controlled manner, layer by layer.

Fundamental Characteristics of Wire-Arc AM:- High deposition rate enabling rapid manufacturing of large parts

- Use of standard metallic materials in wire form, reducing costs

- Ability to produce near-net-shape components with minimal waste

- Compatibility with engineering alloys such as steels, aluminum, and titanium

- Controllable grain structure through precise thermal management

- Scalability for components from several kilos to multiple tons

The synergy between AI and Wire-Arc AM is not just an incremental improvement; it represents a fundamental shift in how we conceive and execute the manufacturing of critical metal components.

AI Integration: Real-Time Process Optimization

The incorporation of artificial intelligence transforms the Wire-Arc AM process from static operation to an adaptive intelligent system. Machine learning algorithms analyze multiple variables simultaneously and perform automatic real-time adjustments to maintain optimal manufacturing conditions.

Parameters Optimized by AI:- Deposition speed dynamically adjusted based on geometry and material

- Electric arc temperature controlled for consistent microstructure

- Nozzle trajectory optimized for uniform and efficient coverage

- Oscillation pattern adapted to specific geometric features

- Shielding gas flow regulated according to environmental conditions

- Thermal management strategies for residual stress control

Defect Reduction and Structural Quality Improvement

The AI-Wire-Arc AM system addresses chronic problems in metal additive manufacturing through early detection and automatic correction of anomalies. The ability to intervene during the process rather than afterward represents a fundamental competitive advantage. 🛠️

Defects Mitigated by AI:- Porosity detected and corrected through energy parameter adjustment

- Internal stresses managed through adaptive scanning strategies

- Cracks avoided through precise thermal cycle control

- Distorted geometries compensated with intelligent toolpath trajectories

- Non-metallic inclusions minimized with optimized gas purging

- Microstructural anisotropy reduced with active thermal management

Prediction of Metallurgical Behavior

The AI algorithms developed at Virginia Tech incorporate advanced predictive models that anticipate metal behavior during critical phases of cooling and solidification. This capability enables proactive interventions rather than reactive ones.

Predictive Aspects of the System:- Resulting microstructure modeling based on thermal history

- Prediction of residual stresses and post-manufacturing distortion

- Optimization of mechanical properties through grain control

- Anticipation of segregation phenomena and phase formation

- Management of phase transformations in complex alloys

- Adaptation to variations in material chemical composition

Industrial Applications and Benefited Sectors

The AI-Wire-Arc AM technology is demonstrating exceptional value in multiple high-demand industrial sectors, particularly where complex metal components are critical for performance and safety.

Highlighted Applications:- Aerospace components: structural brackets, engine supports

- Energy: turbines, components for nuclear and renewable plants

- Automotive: chassis, transmission components, and suspension systems

- Infrastructure: bridge elements, offshore structures

- Defense: armor, components for vehicles and weapon systems

- Medicine: customized implants, specialized surgical instruments

Competitive Advantages and Economic Benefits

The implementation of AI in Wire-Arc AM generates substantial economic benefits through reduction of operating costs, minimization of waste, and optimization of material usage.

Economic and Operational Advantages:- Reduction of up to 40% in manufacturing time through optimized parameters

- Decrease of 60% in wasted material due to reprocessing and rejects

- Improvement of 30% in mechanical properties of manufactured components

- Elimination of 80% of post-production inspections through consistent quality

- Reduction of 50% in energy consumption through process efficiency

- Rapid investment payback through improved productivity

Implications for Manufacturing Sustainability

The Virginia Tech approach contributes significantly to the transition toward sustainable manufacturing through reduction of environmental footprint and resource optimization in metal component production.

Contributions to Sustainability:- Minimization of material waste through additive manufacturing

- Reduction of energy consumed per manufactured component

- Elimination of intermediate processes and additional heat treatments

- Possibility of using recycled materials as feedstock

- Extension of component lifespan through improved structural quality

- Localized production reducing associated transportation and logistics

Conclusion: The Future of Intelligent Metal Manufacturing

The Virginia Tech research on AI and Wire-Arc AM represents a paradigmatic advance in the evolution of metal component manufacturing. By demonstrating that the synergistic integration between artificial intelligence and advanced additive manufacturing technologies can overcome fundamental limitations of traditional processes, it is establishing a new standard for 21st-century manufacturing industry. This technology not only accelerates production and improves quality, but also democratizes access to manufacturing capabilities that were previously reserved for industries with massive resources. As this approach scales and is more widely adopted, it promises to catalyze a fundamental transformation in how we design, manufacture, and use metal components in virtually all sectors of the global economy, laying the foundations for an era of smarter, more efficient, and sustainable manufacturing. 🚀