University of Cádiz boosts industrial repair with 3D printing and digital scanning

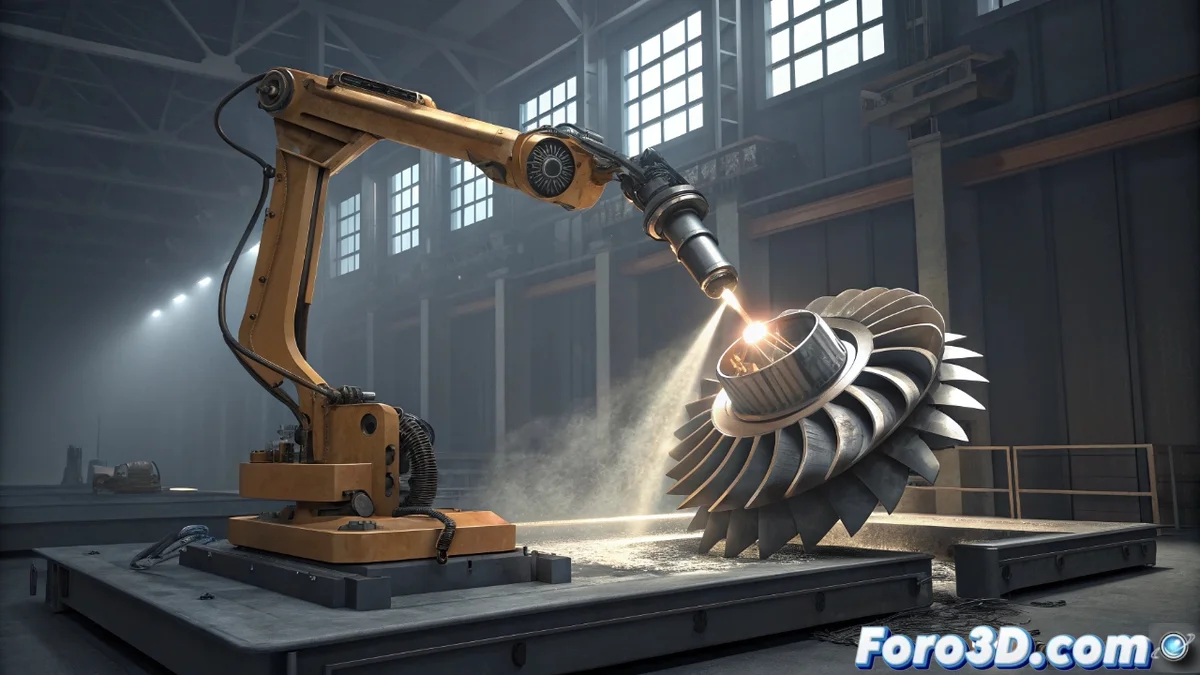

The University of Cádiz has launched a pioneering initiative that integrates cutting-edge technologies such as 3D printing and digital scanning to optimize the repair of metallic components in the industrial sector. This advance in additive manufacturing allows restoring damaged parts with superior precision and efficiency compared to conventional methods, addressing the need for more sustainable practices in industrial maintenance, where total replacement involves high economic and environmental costs. 🚀

Key technologies in the repair process

The system employs high-resolution 3D scanners that capture the exact geometry of the affected components, creating a detailed digital model. Then, using specialized metal 3D printers, material is applied layer by layer to the damaged areas, reconstructing the part to its original specifications. This methodology is compatible with various metal alloys and adapts to sectors such as aeronautics and naval, demonstrating exceptional versatility in real environments.

Main features of the system:- Integration of digital scanning for precise modeling of complex geometries

- Use of metallic 3D printing for controlled material deposition

- Compatibility with multiple alloys and varied industrial applications

This technology not only accelerates repairs but redefines sustainability standards in the manufacturing industry.

Benefits and applications in the industrial sector

Among the most notable advantages is the reduction in repair times by up to 60% compared to traditional techniques, along with significant savings in material costs by avoiding complete replacement. The process ensures uniform quality in interventions and facilitates work with intricately designed parts that would be difficult to restore with old methods. The university is already collaborating with local companies to implement this technology in predictive and corrective maintenance, expanding opportunities for regional manufacturing.

Practical applications:- Quick repair of components in aeronautical and naval industries

- Implementation in preventive maintenance programs to extend equipment lifespan

- Reduction of waste and costs associated with part replacement

Future of industrial repairs

With this advance, it seems that archaic repair methods, based on manual adjustments and excessive welding, will become obsolete. Although some traditionalists may cling to rudimentary techniques, the efficiency and precision of 3D printing and digital scanning mark a turning point in the industry, promoting smart and environmentally friendly solutions. 🌟