Triastek Applies 3D Printing to Manufacture Medications

The traditional pharmaceutical industry produces tablets using standardized methods that restrict how a medication acts in the body. The Chinese company Triastek breaks this paradigm by implementing 3D printing to design and manufacture drugs. This innovation enables more precise management and prediction of the oral release of an active ingredient, marking an evolution in how therapies are conceived. 🧪

Design Drug Release with Precision

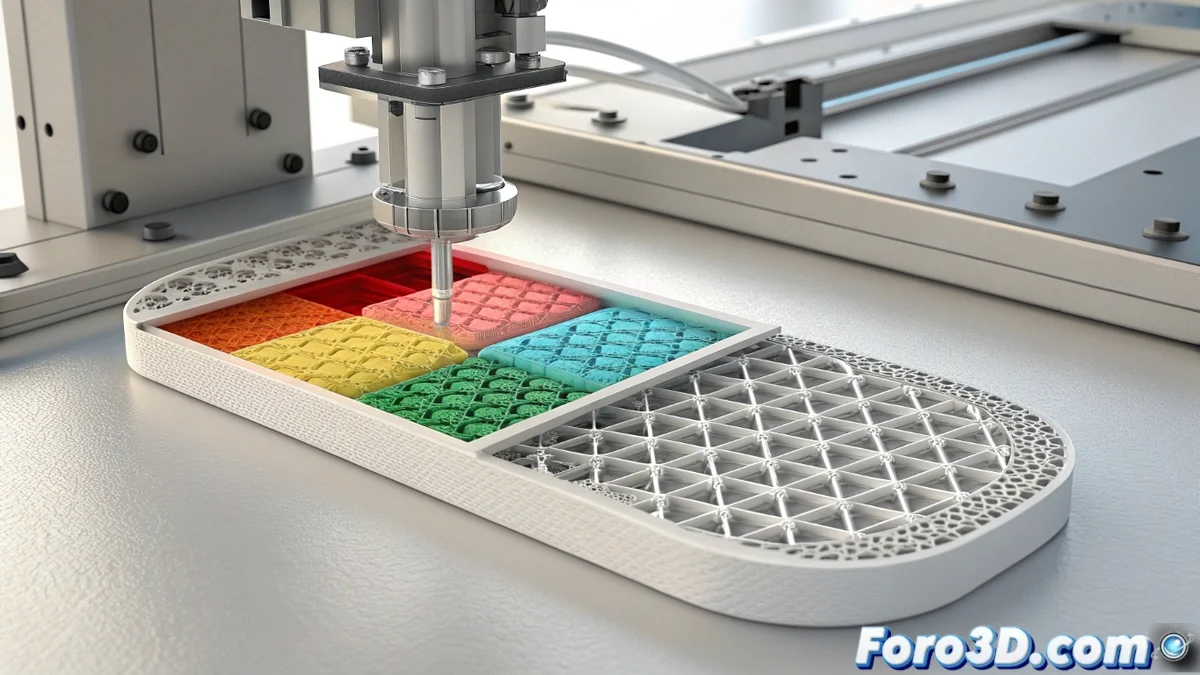

Triastek's technology, called MED, manufactures sophisticated internal architectures within a single pill. This enables programming when and where the medication is released along the gastrointestinal tract. A tablet can be produced that administers multiple doses throughout the day or protects a drug vulnerable to gastric acid. Achieving this level of control was complicated with conventional compression techniques.

Key Advantages of Pharmaceutical 3D Printing:- Allows creating complex internal structures in a single pill.

- Enables programming drug release at specific sites and times.

- Facilitates protecting ingredients sensitive to the gastrointestinal environment.

3D printing is redefining the limits of galenics, allowing unprecedented control over the pharmacokinetics of oral medications.

Accelerate and Optimize Therapy Development

By printing medications, scientists can quickly evaluate and modify different release patterns. This speeds up the process to find the most effective formulation. The method also simplifies manufacturing small batches for clinical trials or personalized treatments. Triastek collaborates with various international pharmaceutical companies to use its technology, which has already received fast-track designations from regulatory agencies in the United States and China.

Current Applications and Collaborations:- Test and adjust release formulations agilely.

- Manufacture small batches for studies or personalized medication.

- Collaborate with global pharmaceutical companies.

The Future of Printed Medication

Of course, this does not mean you will soon print your pills at home; regulations and industrial scaling remain significant obstacles. However, the path to custom-made tablets with tailored release properties appears more achievable than ever, thanks to innovations like Triastek's. 🚀