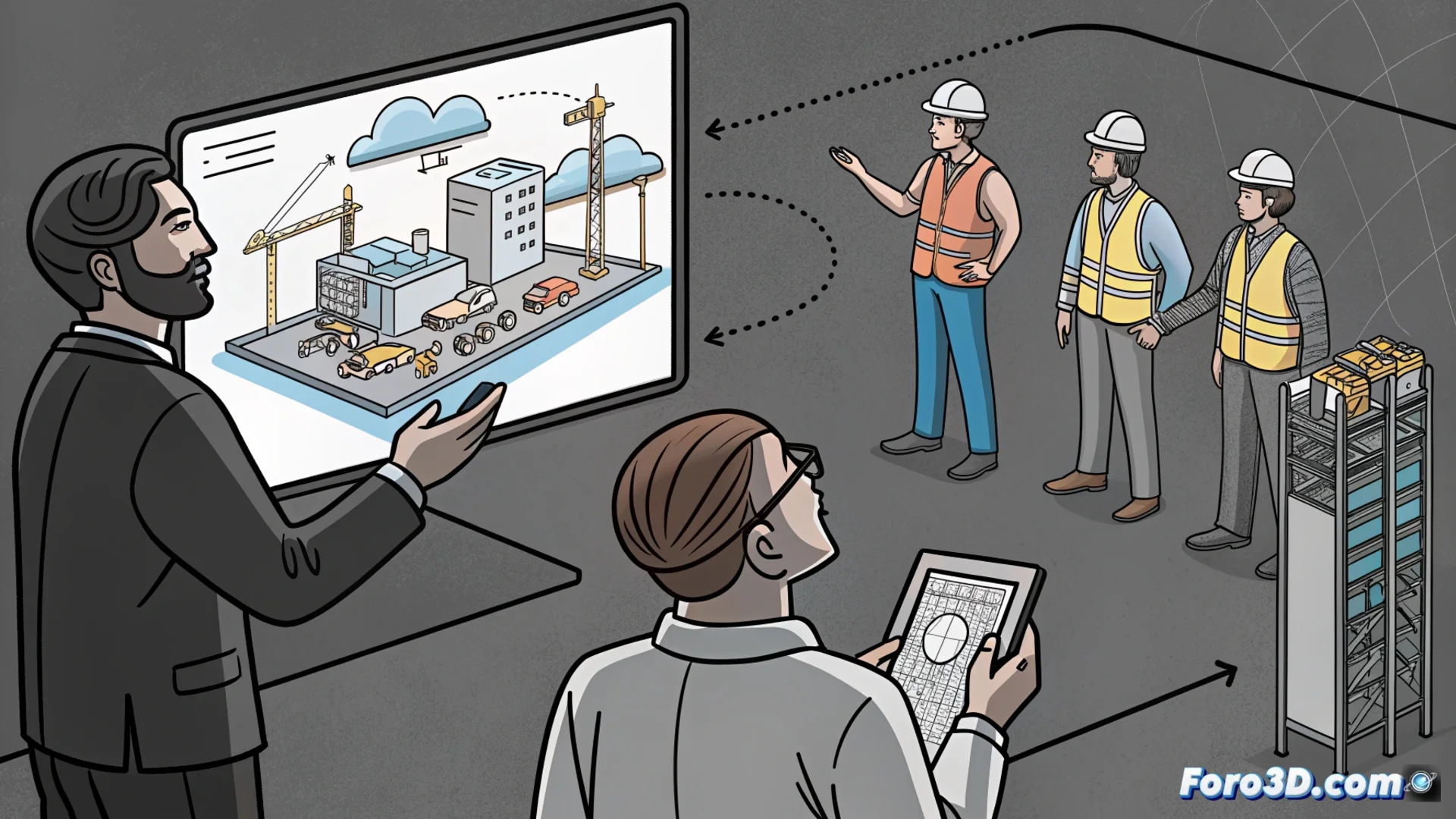

Transform Communication and Document Production with 3D Technology

The 3D digital transformation is redefining traditional methods. Companies now use virtual environments and three-dimensional models to present complex information directly. This approach replaces static documents with experiences where users can explore and understand intuitively. The result is a clearer message and faster review cycles, reducing errors and delays in projects. 🚀

Communicate with Clients Using Interactive 3D Models

To engage with clients, interactive 3D models are essential. Real-time configurators, virtual tours, or operational simulations are implemented. This allows the client to perceive the product in its real context, interact with it, and suggest modifications before any physical manufacturing. Specialized web platforms facilitate sharing these assets, transforming technical presentations into collaborative sessions. The key is selecting the right format and level of detail for each audience, without overwhelming with superfluous data.

Key Tools for Interaction:- Real-time Configurators: Allow customizing products and seeing changes instantly.

- Virtual Tours: Offer immersive walkthroughs of facilities or prototypes.

- Operational Simulations: Show how a product or system operates under specific conditions.

A 200-page PDF user manual can be condensed into an interactive 3D experience. The client avoids deciphering complex diagrams, and technical support reduces calls to clarify confusing instructions.

Optimize Workflows for Producing Technical Documentation

In the field of documentation, 3D technology centralizes and automates processes. A master 3D model acts as the single source of truth for generating drawings, bills of materials, animated assembly instructions, or manuals that use augmented reality. This method eliminates inconsistencies between different documents and saves time, as only the central model needs to be updated. Specialized software connects design with document management, ensuring all derived information is consistent and always up to date.

Advantages of Centralizing with a Master 3D Model:- Data Consistency: All technical documents are generated from the same source, avoiding errors.

- Efficient Updates: Modifying the master model automatically updates all linked documentation.

- Diverse Formats: From traditional 2D drawings to animated guides for augmented reality.

The Tangible Impact on Efficiency and Clarity

Adopting this methodology has a measurable impact. Not only are approval and review processes streamlined, but the end client's understanding is also radically improved. The ability to interact with a virtual product before physical manufacturing prevents costly misunderstandings. Internally, technical teams spend less time correcting documents and more on innovating. Immersive documentation becomes a competitive advantage, transforming a tedious requirement into a value-added tool. 💡