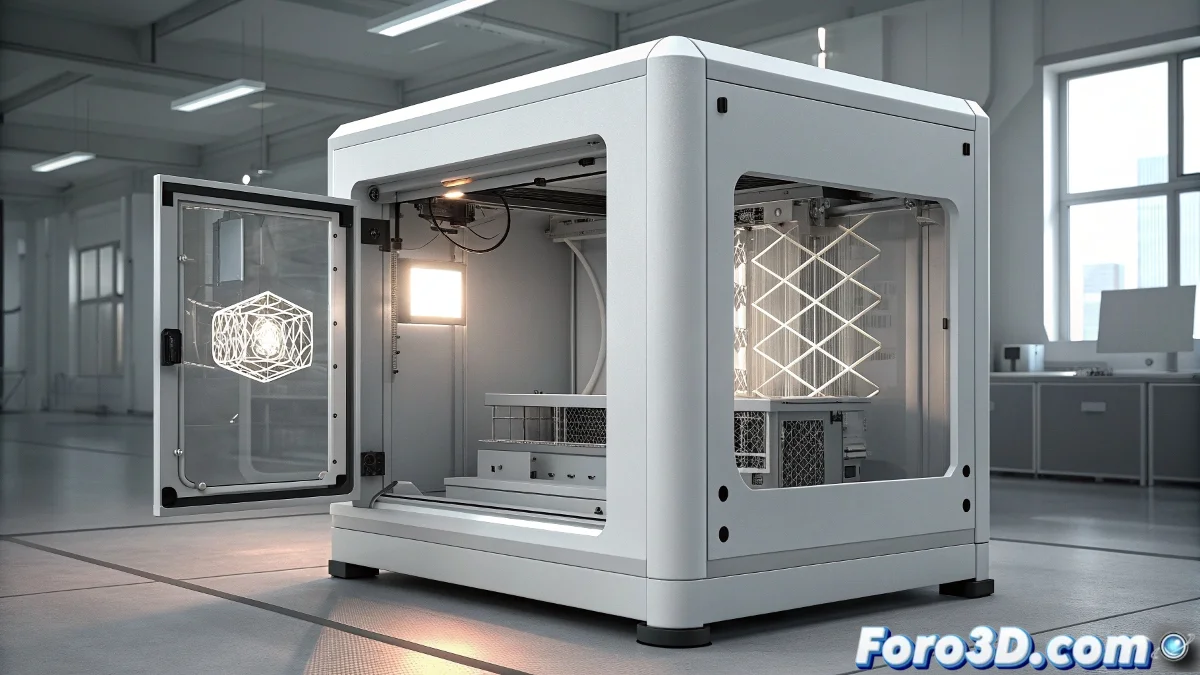

TPM3D S260: when powder turns into perfect industrial parts

3DZ has officially presented in a webinar the industrial 3D printer TPM3D S260, an additive manufacturing solution based on powder bed technology that is redefining the production of functional parts in sectors such as aeronautics, automotive, and medical. This machine, specifically designed for industrial environments, allows the creation of components with geometries impossible to achieve through traditional manufacturing methods, while maintaining the mechanical properties required for critical applications. The S260 represents the maturity of industrial 3D printing, offering repeatability, reliability, and scalability. 🏭

Powder technology for absolute design freedom

What differentiates the TPM3D S260 is not simply its ability to print in powder, but how this technology has been optimized for series production rather than just prototyping. Using the SLS (Selective Laser Sintering) process, the machine fuses powder particles with a high-precision laser, creating fully dense parts without the need for support structures. This allows complex internal geometries, pre-assembled assemblies, and lattice structures that optimize weight without compromising strength. For engineers and designers, this freedom means being able to optimize parts for function rather than for manufacturability.

State-of-the-art technical features

Every aspect of the S260 has been designed with continuous industrial production in mind, from the material handling system to the build environment control.

Manufacturing system and precision

The S260 features a build volume of 260x260x400mm, dimensions optimized for most industrial applications while maintaining excellent dimensional precision. The 100W fiber laser offers balanced speed and resolution, with the ability to achieve layer thicknesses from 0.06mm to 0.15mm depending on the material and application requirements. The double-piston powder recoating system ensures consistent distributions, critical for uniform mechanical properties in production parts.

Key specifications:- build volume: 260x260x400mm

- 100W fiber laser with high-speed scanner

- layer thickness: 0.06-0.15mm

- dimensional accuracy: ±0.1% (minimum ±0.1mm)

Materials and industrial applications

The machine is compatible with a wide range of engineering thermoplastics including Nylon 12, Nylon 11, TPU, and composites with glass, aluminum, or carbon fiber loading. Each material has been optimized to offer specific properties: from rigid, impact-resistant parts to flexible and durable components. The material management system includes mixing and recycling stations that allow reuse of unsintered powder, significantly reducing operating costs in continuous production.

The TPM3D S260 doesn't print prototypes, but end-use parts that fly, drive, and save lives.

Automation and industrial workflow

Designed for integration into production lines, the S260 includes automation features such as automated powder loading and unloading, integrated post-processing system, and Industry 4.0 connectivity for remote monitoring and control. The build preparation software allows automatic nesting of multiple parts, optimizing build volume usage and reducing cost per part. Integrated sensors continuously monitor critical parameters such as chamber temperature, oxygen levels, and powder quality, ensuring lot-to-lot consistency.

Automation features:- automated material loading and unloading

- precise build environment control

- continuous monitoring of critical parameters

- Industry 4.0 integration

Applications in high-value sectors

In the aeronautical sector, the S260 produces lightweight components with optimized structures that reduce weight and fuel consumption. In medical, it creates customized implants and surgical guides with geometries adapted to each patient. In automotive, it manufactures manufacturing tools, customization components, and competition vehicle parts. The ability to produce small batches or unique units economically viable is transforming traditional supply chains. ✈️

Application sectors:- aeronautics: lightweight and optimized components

- medical: customized implants and instrumentation

- automotive: customization and tools

- consumer goods: customized products

In the end, the TPM3D S260 demonstrates that additive manufacturing has reached industrial maturity, though it will probably make traditional manufacturing methods wonder why they didn't think of this before. 🔩