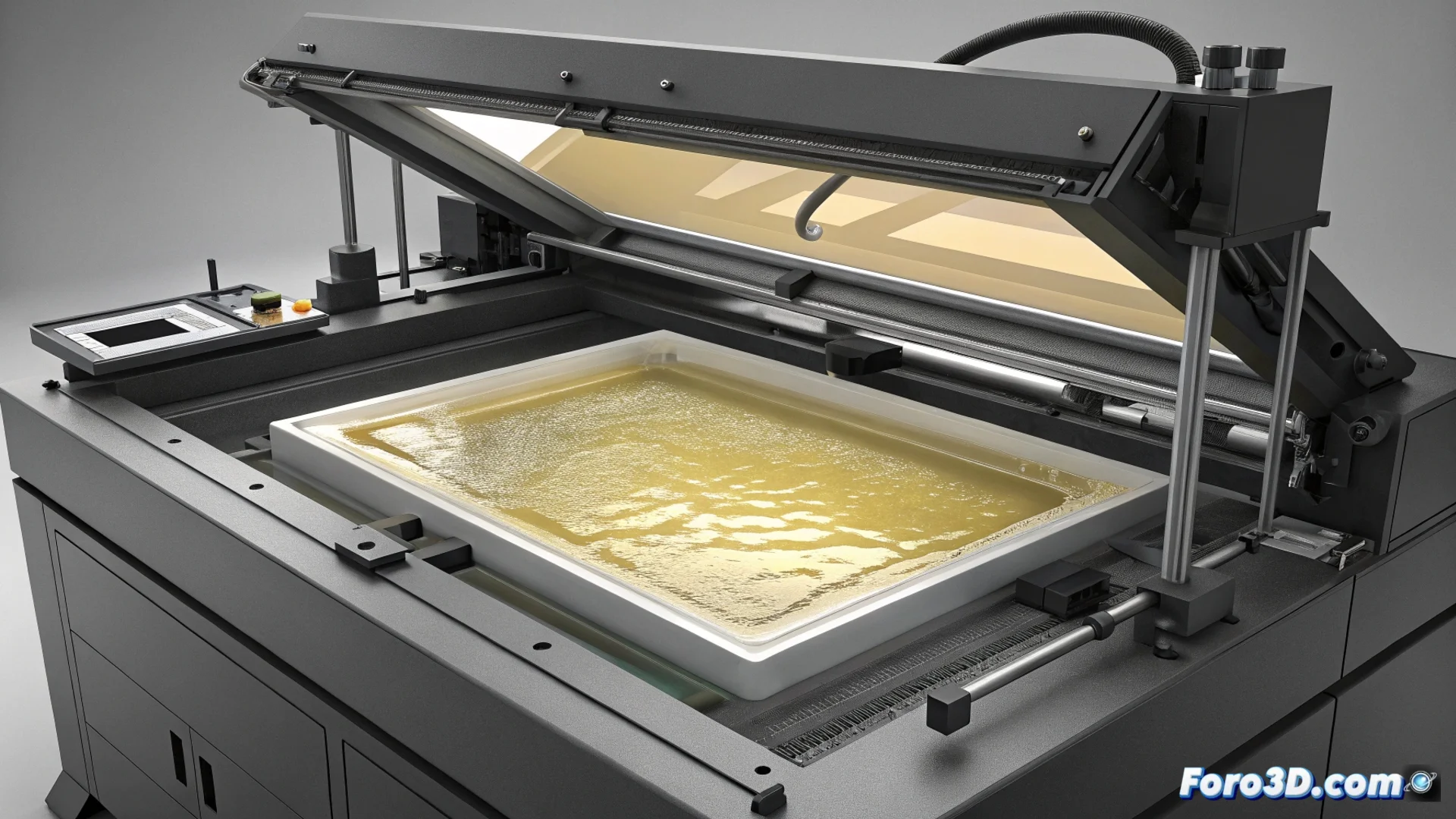

The Weight of the Resin Deforms the Film in Large Printing Tanks

In the field of resin 3D printing, large-volume tanks present a unique physics challenge. The mass of liquid resin they contain generates constant pressure on the membrane, whether FEP or ACF. This force can cause the center of the film to yield, creating a slight concavity that is critical for the process's precision. 🧪

The Direct Impact on the Printing Process

This deformation, although often imperceptible to the naked eye, modifies the working plane. The surface ceases to be completely flat, altering the uniform distance essential between the LCD screen (or light source) and the build platform during the initial layers. This change is the origin of several adhesion and quality issues.

Main consequences of a sagging film:- Compromised leveling: If you calibrate the platform against a taut and empty film, when filling the tank, the actual distance in the center will be greater, causing the first layer not to adhere well in that area.

- Variable separation force: When peeling each layer, the film must flex more in the depressed area, increasing mechanical tension on the model and potentially causing it to detach.

- Inconsistent adhesion: The lack of uniformity in the first layer height makes adherence to the build plate uneven between the center and the edges.

A small physics challenge in the world of millimeter precision: the building material, in its liquid state, complicates the start of the process.

Methods to Mitigate Film Sagging

To counteract this phenomenon, there are approaches both at the hardware design level and user configuration adjustments. The goal is to restore uniformity or compensate for its effects to achieve successful prints.

Practical Compensation Strategies:- Structural Reinforcement of the Tank: Some manufacturers incorporate a more rigid base or use thicker, more resistant films to minimize flexing under load.

- Leveling Under Real Conditions: An effective method is to calibrate the platform with the tank already filled with resin, thus simulating the pressure that will exist throughout the print.

- Adjusting Base Layer Exposure: Slightly increasing the exposure time for the first layers can help ensure they adhere correctly in the affected central area.

- Respecting the Recommended Layer Thickness: Using