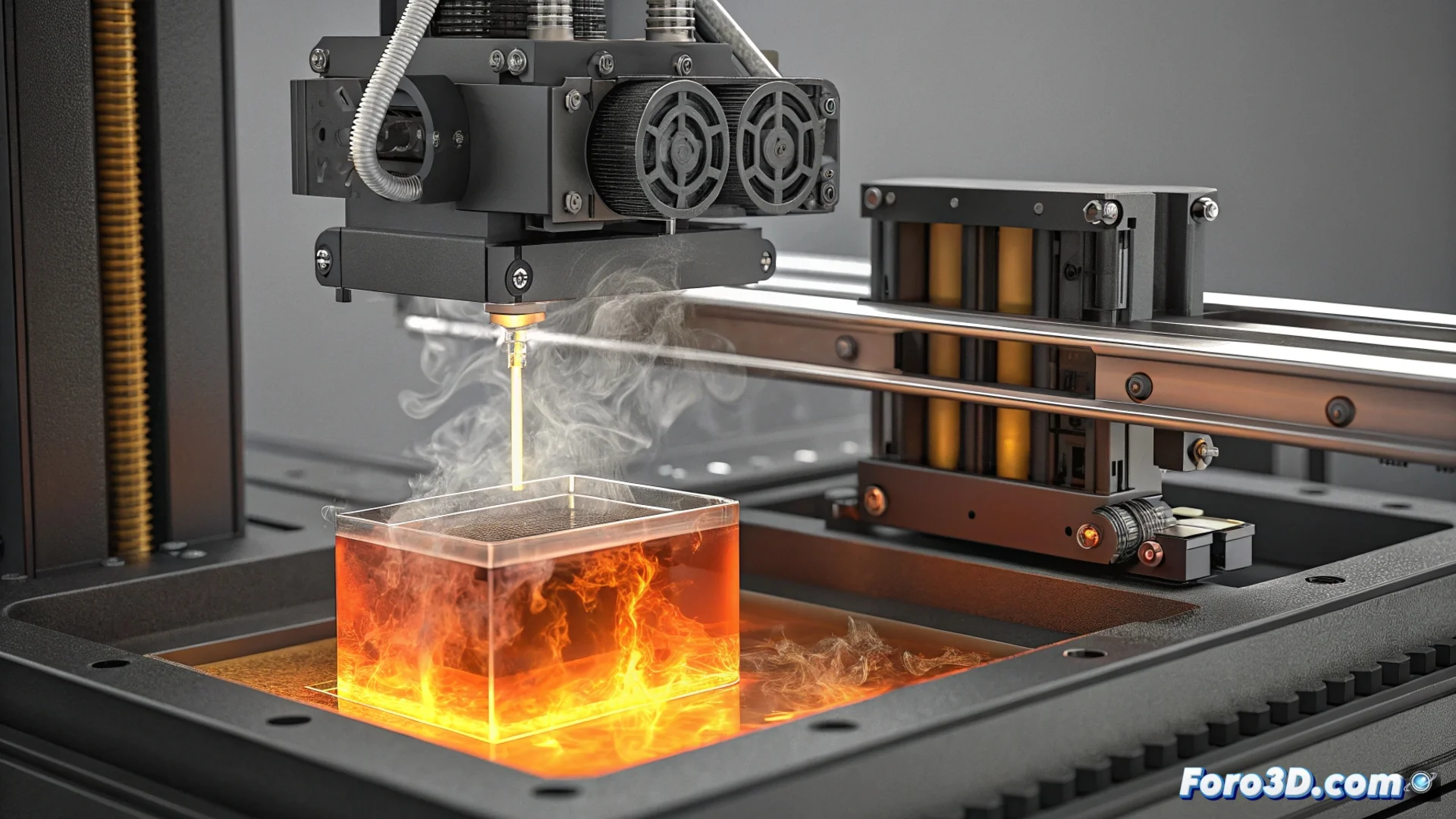

The Uniformation GKTWO Printer and Its Risk of Leaks in the Resin Heater

The Uniformation GKTWO 3D printer integrates a system that heats the resin tank to optimize the printing process. This mechanism aims to make the resin flow better by reducing its viscosity. However, a problem reported by users involves the resin leaking into the interior of the heating module. 🚨

The Origin of the Problem: Sealing and Handling

The leak generally occurs due to two main reasons. The first is an imperfect seal between the tank and the heating base. The second arises from handling or cleaning the tank incorrectly, which can compromise the sealing gasket. Any small gap is enough for the liquid resin to begin leaking.

Consequences of an Active Leak:- The resin invades the heating elements and nearby electrical circuits.

- It can damage the machine's temperature control.

- There is a high risk of short circuit that can permanently damage the electronics.

An electrical failure due to spilled resin not only renders the printer unusable but also poses a danger to the operator.

How to Prevent Resin Leaks

To avoid this mishap, it is essential to adopt proactive maintenance habits. Regular visual inspection is the first line of defense.

Key Prevention Steps:- Frequently check the perimeter seal of the tank and the coupling surface to the heater.

- Ensure there are no cured resin residues or dirt that prevent a perfect hermetic seal.

- Handle the tank carefully during its removal, cleaning, and reinstallation.

What to Do If You Detect a Leak

If you observe moisture, dripping, or resin accumulation outside the tank limits, you must act quickly and cautiously. The priority is to stop any ongoing print immediately.

Leak Response Protocol:- Disconnect the printer from the power grid to eliminate all risk.

- Clean the affected area with isopropyl alcohol and lint-free cloths, with great care.

- Do not use the machine again until verifying that the leak source is completely sealed and the components are dry.

- If there is any doubt about the extent of the damage, contacting official technical support is the safest option.

Innovating in resin heating brings new technical challenges. In the case of the GKTWO, monitoring the seal integrity becomes a crucial part of routine maintenance to protect the investment and ensure safety. 🔧