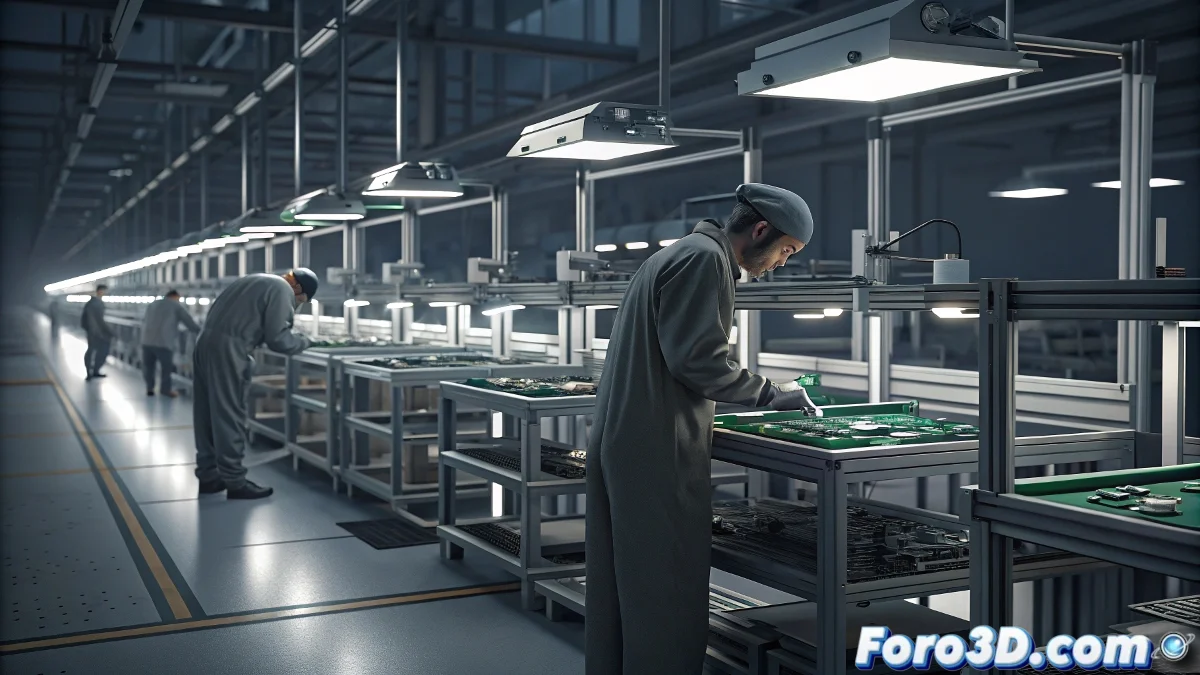

The Semiconductor Crisis Paralyzing the 3D Printing Industry

The 3D printing sector is currently in a critical situation due to the global shortage of electronic components, a problem that is keeping costs high and delivery times extraordinarily long for most equipment available on the market. 🚨

Direct Impact on Manufacturers and Consumers

Leading brands like Creality, Prusa Research, and Ultimaker have had to completely restructure their manufacturing schedules, while distributors are managing waiting lists that are now measured in months instead of weeks. This reality equally affects enthusiasts looking for their first printer and corporations that urgently need to expand their digital manufacturing capacity.

Immediate Consequences:- Average price increase of 25-40% for mid-range and high-end equipment

- Delays of between 3 and 6 months in deliveries of new orders

- Limited availability of models with more advanced technology

"The paradox is evident: just when 3D printing promised to democratize manufacturing, tiny components like 2x2 cm chips are putting an entire decentralized industrial revolution on hold"

Effects on Innovation and Technological Development

The most significant advances in 3D printing technology are experiencing the greatest consequences, as new generations of printers require more powerful processors and specialized components for advanced functions. The shortage of STM32 microcontrollers, Raspberry Pi chips, and graphics processing units is especially slowing the evolution of resin printers and dual extrusion systems, where computational performance is fundamental to the final quality of the produced parts. 💻

Affected Functionalities:- Automatic bed leveling correction systems

- Intelligent real-time failure monitoring mechanisms

- Advanced connectivity and remote control capabilities

Adaptation Strategies and Emerging Solutions

Faced with this prolonged situation, various companies are implementing creative strategies to mitigate the impact. Some manufacturers are redesigning their motherboards to use available alternative components, although this involves reprogramming firmware and conducting exhaustive compatibility tests. Other approaches include creating strategic chip reserves, diversifying suppliers globally, and establishing direct partnerships with semiconductor manufacturers. 🤝

Alternatives for Consumers:- Wait for the specific desired model, accepting long wait times

- Opt for available alternatives with reduced technical specifications

- Pay significant premiums on the secondary market to obtain equipment

Future Outlook and Conclusions

The semiconductor crisis represents a structural challenge for the 3D printing industry, forcing all players in the ecosystem to develop new resilience strategies. While manufacturers seek technical and logistical solutions, end users face complex decisions that affect their projects and operations. This situation underscores the global interdependence of supply chains and the vulnerability of advanced technologies to the shortage of seemingly simple but critical components. 🔄