The Revolution of Industrial Robotic Arms: KUKA, FANUC, and ABB Leading Automation

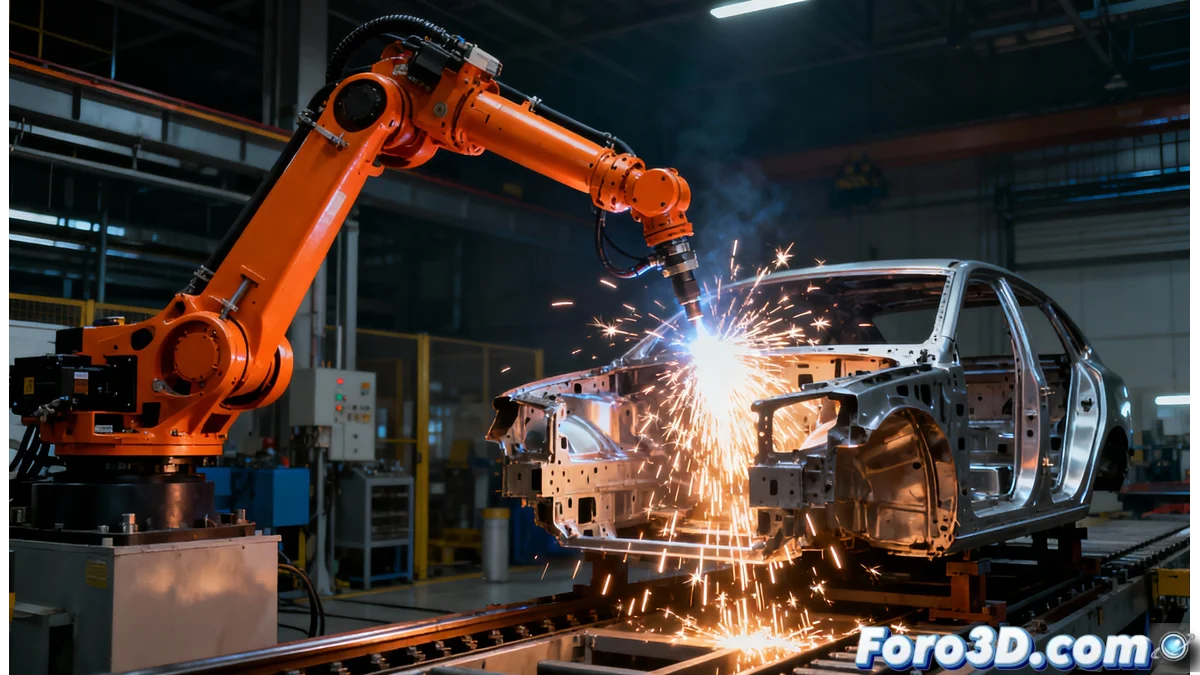

Industrial automation has undergone a paradigm shift thanks to the massive integration of articulated robotic arms. These machines, from elite manufacturers like KUKA, FANUC, and ABB, have ceased to be a luxury and have become the backbone of modern manufacturing. Their ability to execute complex movements with supernatural speed and accuracy has not only increased productivity but has also completely reconfigured the dynamics and safety in plants around the world. 🤖

The Three Giants of Robotics and Their Fields of Application

The market for industrial robots is clearly led by a trio of giants, each with its own philosophy and distinctive strengths. KUKA, of German origin, is praised for its exceptional adaptability and seamless integration into complex and dynamic manufacturing systems. For its part, the Japanese FANUC has earned a legendary reputation for building machines with almost indestructible robustness, designed to operate in mass production environments with unwavering reliability and minimal maintenance requirements. The Swiss ABB meets the demand for absolute precision and is a pioneer in the development of collaborative robotics (cobots), where humans and machines work side by side. Their main fields of action are fundamental for industry:

Key Automated Processes:- Robotic Welding: Whether by arc or spot, they guarantee perfect, repeatable, and high-strength joints, essential in sectors like automotive. 🔧

- Painting and Coating Application: They achieve uniform layers, minimizing material waste and exposing zero workers to toxic fumes.

- Precision Assembly: From placing microchips on a motherboard to assembling complete engines, their dexterity is irreplaceable in electronics and automotive.

- Palletizing and Material Handling: They move boxes, bags, or heavy components at a constant and tireless pace, optimizing internal logistics.

The paradox of intelligent automation: machines capable of superhuman tasks that still depend on human ingenuity for initial guidance and programming.

The Undeniable Advantages That Justify the Investment

The global adoption of these systems is not a fad, but a strategic decision based on quantifiable benefits. Sub-millimeter precision eliminates errors due to fatigue or distraction, ensuring consistent and superior product quality. Their operational cycle speed allows achieving production volumes that challenge any manual limit. Additionally, they are the perfect employees for endless shifts: they operate 24/7 without rest, maximizing the return on investment in machinery and factory space. The programming flexibility, often through intuitive demonstration-based learning interfaces, allows quick reassignment to new tasks, an invaluable value in the era of mass customization. 💡

Key Competitiveness Factors:- Maximized Efficiency and Productivity: Reduction of cycle times and increase in output.

- Improved Workplace Safety: They free personnel from monotonous, dangerous, or ergonomically harmful tasks.

- Guaranteed Consistency and Quality: Every piece or process is identical to the previous one, reducing scrap and rework.

- Operational Flexibility: Ability for quick reconfiguration to adapt to new products or market demands.

The Future is Collaborative: Beyond Pure Automation

The horizon is not limited to cages with robots performing isolated tasks. The true evolution lies in the synergy between humans and machines. The latest generation of cobots are designed to work safely alongside operators, combining the robot's strength, precision, and endurance with human contextual intelligence, adaptability, and decision-making. This symbiosis is redefining roles in the factory, where the worker becomes a supervisor and programmer of intelligent systems, focusing on higher value-added tasks. The robotic revolution, far from replacing us, is elevating us to a new level of industrial capability. 🚀