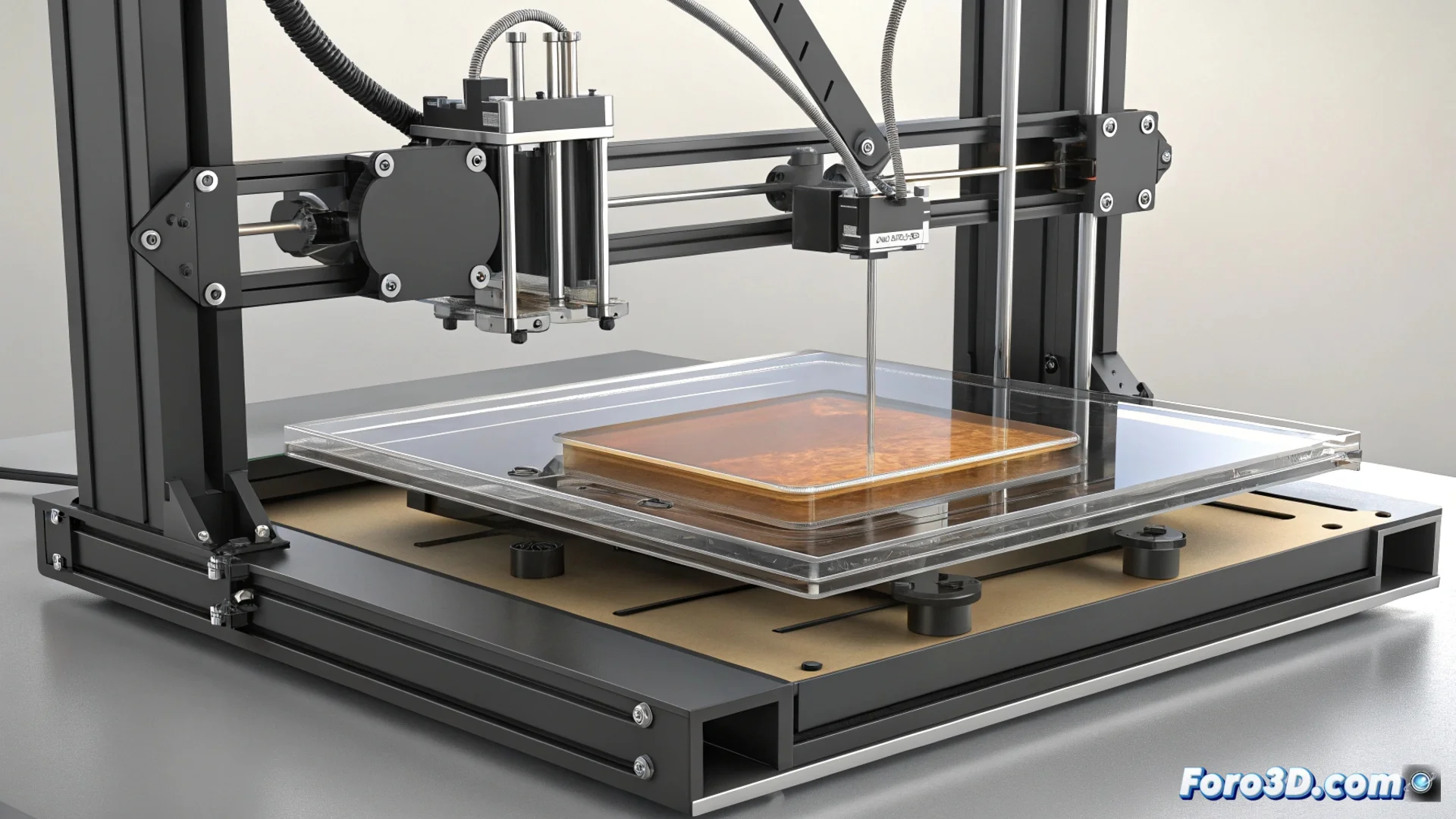

The Phrozen Sonic Mega 8K and Its Tilting Mechanism for Peeling Off Layers

Large-screen resin printers, like the Phrozen Sonic Mega 8K, face an engineering challenge: the enormous suction force generated between the build plate and the FEP. To overcome it without damaging the models, this machine implements a precise peel-off movement that tilts the tank. 🛠️

A Key Movement That Defines Speed

The process is not limited to lifting the plate. In each layer, the resin tank tilts at a controlled angle to separate the FEP film from the freshly cured part. This mechanical step adds seconds per cycle, which multiply in prints with thousands of layers. That's why the high exposure speed of its 8K screen does not directly translate into fast prints; it's a balance between reliability and raw speed.

Parameters that the user can adjust to optimize:- Increase layer thickness: Reduces the total number of layers needed to complete the model.

- Set higher movement speeds: Speeds up the time it takes for the plate to rise and descend, if the resin allows it.

- Use fluid resins: Resins with low viscosity generate less suction force, making peeling easier.

The tilting mechanism is the price to pay for reliability in large-format prints. A successful print that takes a little longer is preferable to a failed one that requires cleaning the tank.

The Inherent Trade-Off in the Design

This system prioritizes protecting the print and ensuring its success, especially in large volumes where a failure is more costly. It introduces an operational pause in each layer, a time invested in executing the peeling movement in a controlled and uniform manner.

Comparison with other systems:- Simple linear mechanisms: Can offer greater pure speed, but with a higher risk of damaging the model on large screens.

- Tilting mechanism: Adds time per layer, but minimizes failures due to abrupt peeling, ideal for those who value consistency.

- User choice: Depends on whether absolute speed or success rate in large parts is prioritized.

Maximizing the Machine's Potential

Although the tilting movement is a constant in the operation of the Sonic Mega 8K, fine-tuning the parameters in the slicing software allows mitigating its impact on total time. The user has in their hands the ability to optimize the process, choosing suitable resins and adjusting settings to get the most out of the hardware. In the end, understanding this design trade-off is key to managing expectations and obtaining the best results. ✅