The Memjet DuraLink Printhead Prints Circuits for AI Hardware

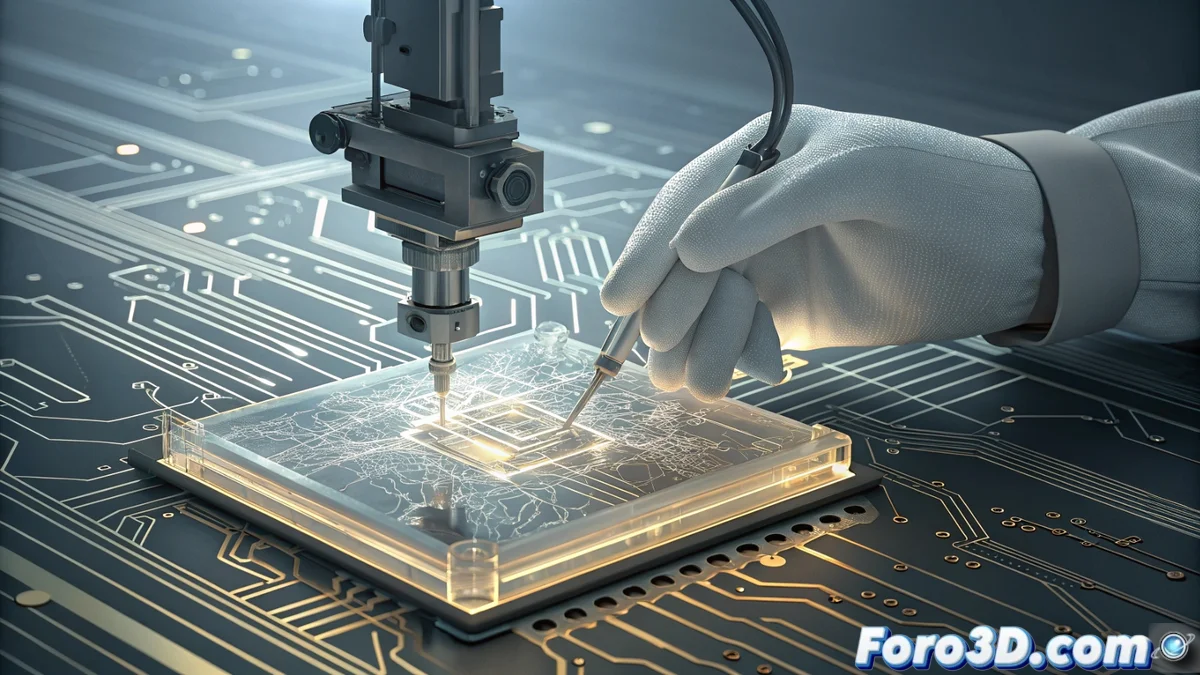

The Memjet DuraLink printhead is a key component in additive manufacturing that deposits functional materials. Its main purpose is to print layers of conductive ink and dielectric ink directly onto flexible materials, enabling the creation of complete electronic circuits. This technique goes beyond graphic printing to venture into advanced fields such as research in artificial intelligence. 🚀

Accelerating the Development of Neuromorphic Hardware

In the field of AI, this system is useful because researchers can use it to manufacture experimental neuromorphic substrates. These substrates seek to imitate the structure and functioning of biological neural networks. The ability to print complex circuit patterns and integrated sensors directly facilitates the exploration of new hardware architectures. Thus, the time needed to go from a concept to a functional physical prototype is reduced, accelerating iterations in designs.

Key advantages of this approach:- Allows for rapid prototyping and customizing designs without using traditional processes that are slower.

- Facilitates exploring innovative hardware architectures for artificial intelligence.

- Significantly reduces the cycle from conceptual design to having a functional device.

Functional printing customizes sensors and devices, integrating sensing and processing functions into a single piece.

Customizing Sensors and Smart Devices

This technology enables the manufacture of smart sensors and flexible circuits that adapt to unconventional shapes. This is fundamental for developing embedded AI devices in wearables, soft robotics, or human-machine interfaces. By printing the electronic components directly, sensing and processing functions are integrated into a single piece. This approach opens the door to creating more specialized and efficient artificial intelligence hardware for specific tasks.

Main applications:- Develop wearables with integrated and flexible electronics.

- Create advanced interfaces for soft robotics.

- Manufacture specialized AI hardware for specific tasks.

A Persistent Technical Challenge

Of course, the biggest challenge is not printing the circuit, but preventing the conductive ink from turning into an impossible-to-debug scribble when the design is complex. Maintaining the precision and integrity of the conductive tracks in intricate patterns is crucial for neuromorphic hardware prototypes to work correctly on the first try. 🧠