The magnetic bed of FDM printers loses strength over time

A common problem in many Fused Deposition Modeling (FDM) 3D printers is that the magnetic field that holds the flexible steel sheet in place weakens progressively. This deterioration accelerates significantly when the bed is repeatedly subjected to high temperatures above 100°C. The direct consequence is that the print sheet no longer holds firmly, which can ruin hours of work. 🧲

Signs indicating a weak magnet

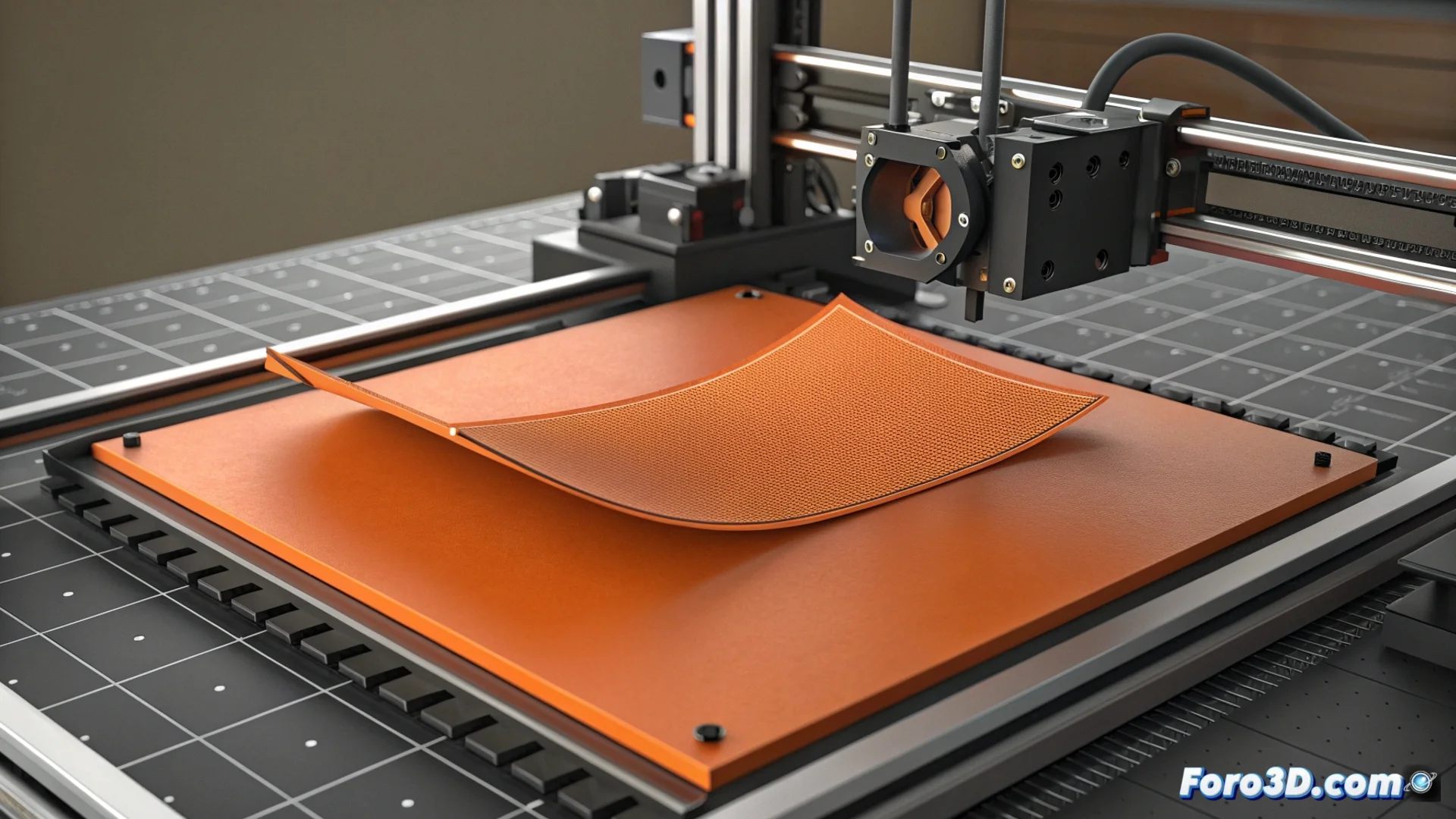

Identifying that the magnetic bed has lost power is key to avoiding failures. It's not just that the sheet doesn't adhere well at the start; the problem usually manifests during the printing itself. If the sheet shifts with a light touch or if the corners lift while printing, these are clear symptoms. Even a small bump when removing a part can be enough to completely misalign it, compromising the essential flatness of the work surface.

Main indicators of wear:- The steel sheet slides or moves with minimal pressure.

- The corners of the sheet lift during the printing process, especially on large parts.

- The sheet does not lie completely flat and firm after placement, with noticeable play.

This is the moment when your printer decides it prefers abstract art and moves the sheet to create a unique sculpture, even if you didn't ask for it.

Options to solve the adhesion problem

When the magnetic strength decreases noticeably, action is necessary. Thoroughly cleaning both the bed and the back of the sheet can help by removing dust particles or residues that act as a barrier. Adjusting the bed temperature to not exceed the limits recommended by the manufacturer can slow future wear. However, these are temporary solutions for very mild cases.

Effective and lasting solutions:- Replace the component: The most direct and reliable option is to replace the entire magnetic bed with a new one.

- Keep the bed within a safe temperature range to preserve the magnet's properties.

- Ensure periodic cleaning of both surfaces to maximize contact and adhesion.

Conclusion to keep your prints under control

The loss of magnetism in the print bed is normal wear,