The LCD screen of the Elegoo Mars 4 Ultra printer is a consumable component

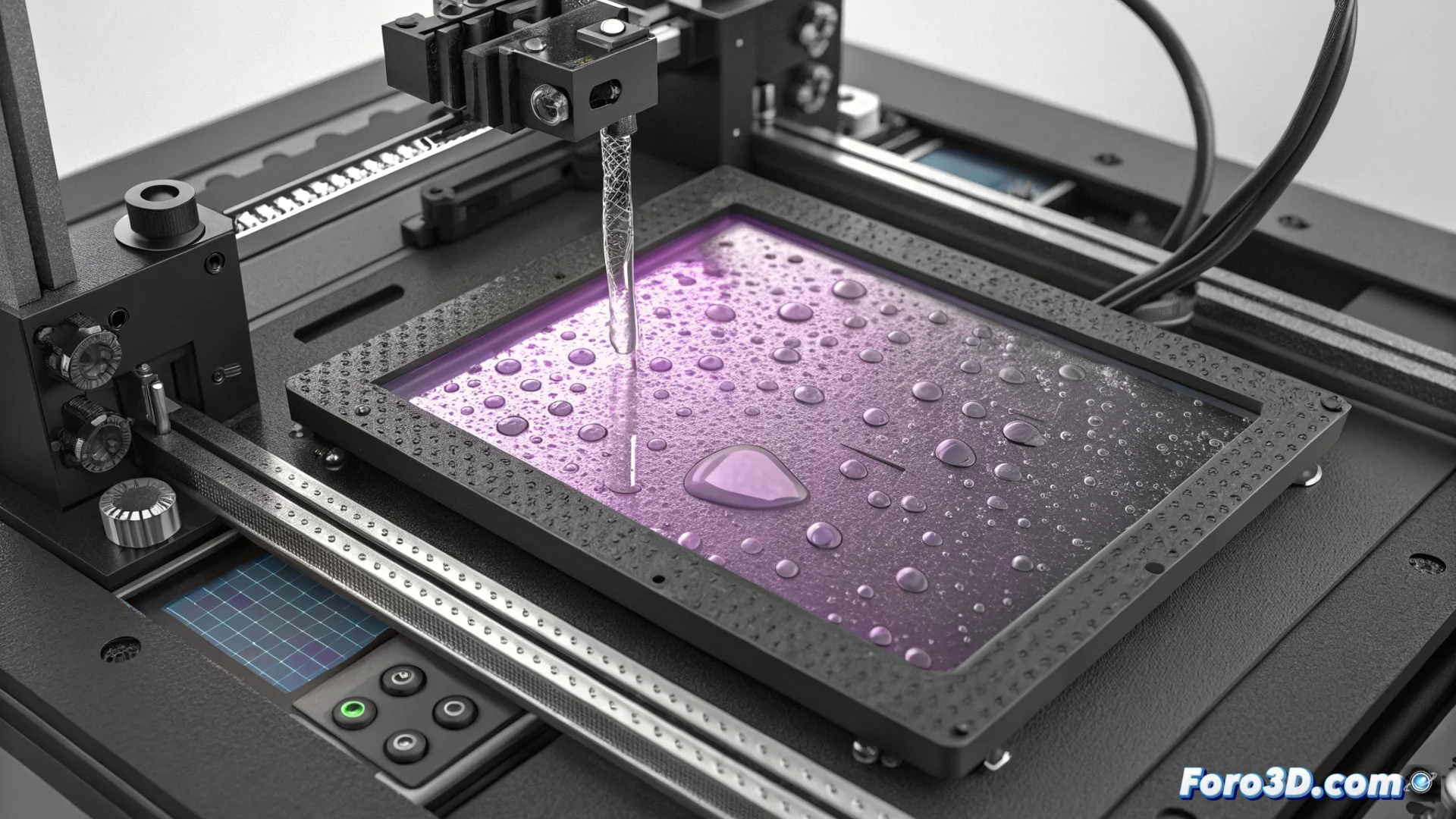

In resin 3D printing, the LCD screen acts as a UV light mask. Over time, this component suffers wear and can fail, directly affecting the quality of your models. It is crucial to understand that its lifespan is limited. 🖥️

Understanding pixel failures on the screen

A dead pixel remains off, constantly letting UV light through and creating a hole in every layer. A stuck pixel stays always on, solidifying the resin at a precise point and forming an unwanted solid column. These defects, whether from use or manufacturing, are irreparable and require replacing the entire screen.

How to detect defective pixels:- Access the printer's maintenance menu and run the screen exposure function.

- A functional screen displays a rectangle of light uniform and without anomalies.

- Fixed black spots indicate dead pixels; fixed white light spots or lines indicate stuck pixels.

Any defect in the screen is precisely replicated in every layer of all your prints, compromising the final result.

Procedure for replacing the LCD screen

When you identify a failure, the only solution is to install a specific replacement module for the Mars 4 Ultra model. The process is delicate but systematic.

Key steps for replacement:- Unplug the printer and carefully open the bottom casing to access the electronics.

- Disconnect the flat cable from the damaged screen and remove the old module.

- Install the new screen, firmly connect its cable, and secure the unit in place.

Final adjustment after the change

After installing the new screen, it is essential to calibrate the build platform. This step compensates for possible minimal differences in the thickness of the new LCD panel and ensures that the first layer adheres correctly. The irony of this technology is that the component that projects the light, essential for building, can fail without warning, reminding us of its fundamental role in the process. 🔧