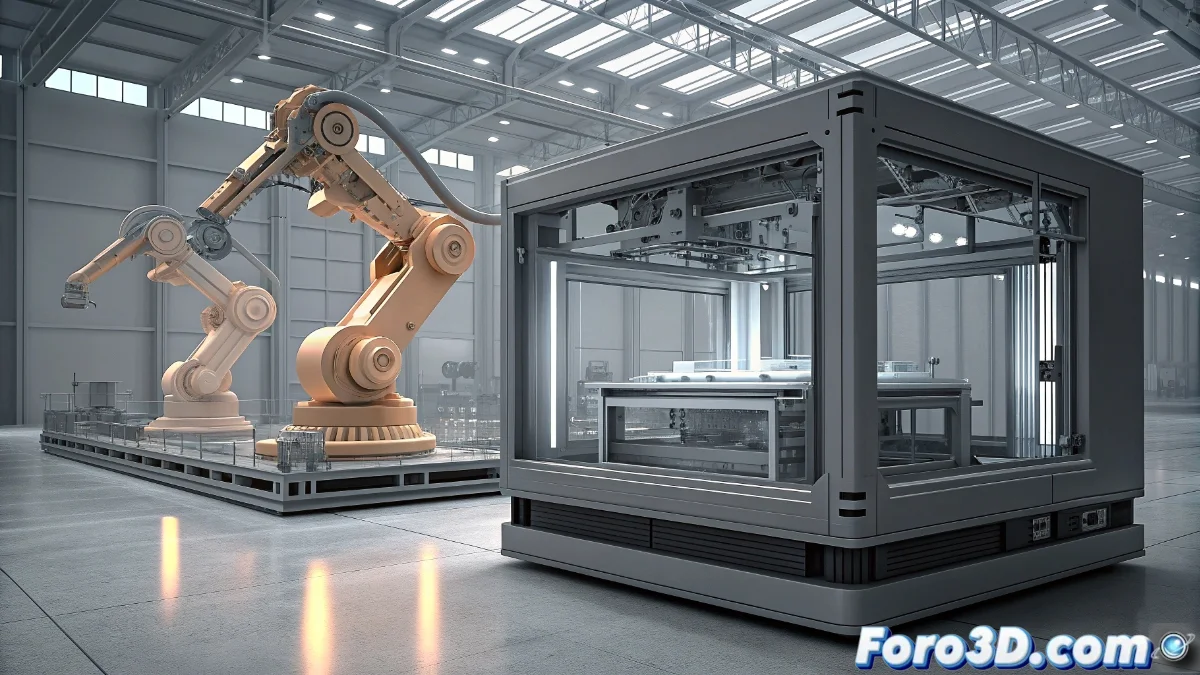

The Industrial Revolution Arrives with 3D Systems' SLA 825 Dual

Additive manufacturing takes a qualitative leap with the new standard set by 3D Systems through its SLA 825 Dual system, specifically designed for high-demand production environments where millimeter precision and repeatability are fundamental requirements. This innovative solution combines stereolithography technology with an innovative dual-laser system that dramatically increases production speed without sacrificing excellence in the finish of large-format parts, positioning itself as ideal for industries such as aeronautics, automotive, and consumer goods where consistency in results is determinant 🚀

Revolutionary Technical Specifications

The heart of the SLA 825 Dual beats with two high-power lasers operating synchronously on the same platform, achieving a substantial reduction in manufacturing times while preserving the most demanding resolution standards. It features an extraordinary print capacity of 1500x750x550 mm, facilitating the creation of large-sized components or multiple parts in a single process. It employs cutting-edge materials such as high-temperature resistant resins and advanced composites that guarantee superior mechanical properties and optimal dimensional stability, expanding its applicability from accelerated prototyping to final component production 🔧

Key Features of the System:- Two high-power lasers working simultaneously for maximum efficiency

- Build volume of 1500x750x550 mm for large-sized parts

- Compatibility with specialized high-temperature resins and advanced composites

The implementation of dual-laser technology marks a before and after in industrial additive manufacturing, establishing new productivity parameters without compromising quality

Competitive Advantages in the Industrial Landscape

This equipment stands out as a comprehensive solution for corporations seeking to optimize their production processes, integrating advanced build management software and automated post-processing options. Its ability to produce parts with polished surfaces and extremely fine details makes it ideal for molds, tooling, and functional elements that traditionally required slower and more expensive conventional methods. Additionally, its robust construction and operational reliability ensure uninterrupted operation in 24/7 manufacturing environments, backed by 3D Systems' global technical support 💼

Main Operational Benefits:- Enhanced build management software and automated post-processing

- Capability to produce parts with exceptional surface finishes

- Proven reliability for continuous operation in 24/7 environments

Investment with Guaranteed Return

Although the initial investment may represent a challenge for some budgets, the value provided more than justifies the acquisition when considering the system's enviable precision and production capabilities. The tears of initial outlay will dry quickly in the face of evidence of components manufactured with exceptional quality and optimized production times that will revolutionize any industrial workflow 💎